Catalytic conversion catalyst regenerator

A catalytic conversion and catalyst technology, applied in the direction of catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of pressure fluctuation, too low dense phase bed, uneven distribution of main air, etc. To achieve the effect of uniform temperature distribution, not easy to dilute phase over-temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

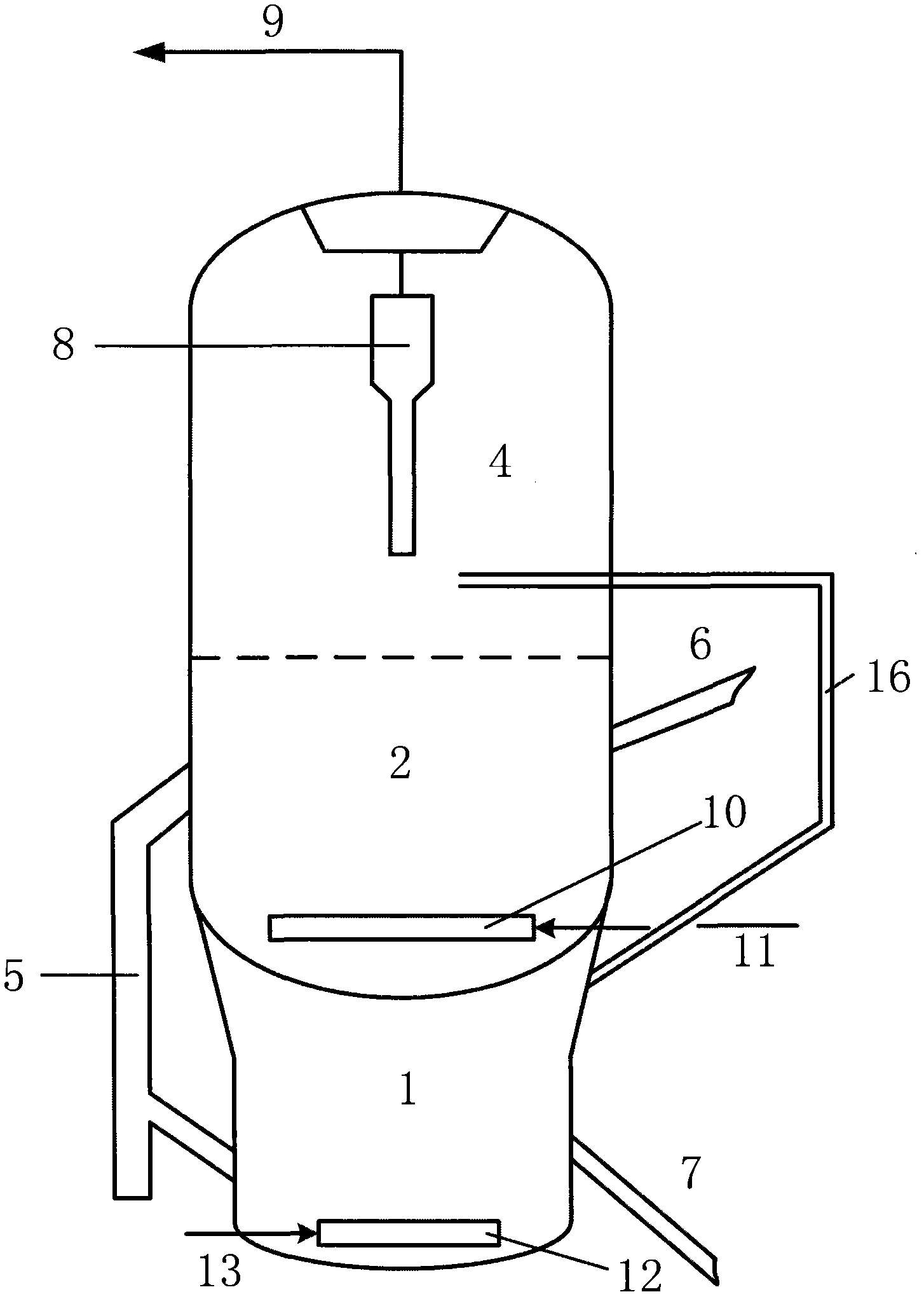

[0036] figure 1 It is a schematic diagram of the basic equipment of Embodiment 1 provided by the present invention.

[0037] Such as figure 1 As shown, the buffer zone 1, the regeneration zone 2 and the settlement zone 4 are arranged vertically from bottom to top. The cooling zone 5 is juxtaposed between the regeneration zone 2 and the buffer zone 1. The regeneration zone 3 is a single-stage regeneration method, and the regeneration zone 2 and the settlement zone Zone 4 adopts direct connection to the vessel wall. The standby catalyst from the reactor enters the regeneration zone 2 through the standby inclined pipe 6 and is evenly distributed on the upper part of the dense phase bed through the distributor. The main air enters from the bottom of the regeneration zone 2 through the pipeline 11 from the main air distribution plate 10 and flows upward. It comes into contact with the spent catalyst flowing downward by gravity in countercurrent and the coke combustion reaction occurs,...

Embodiment approach 2

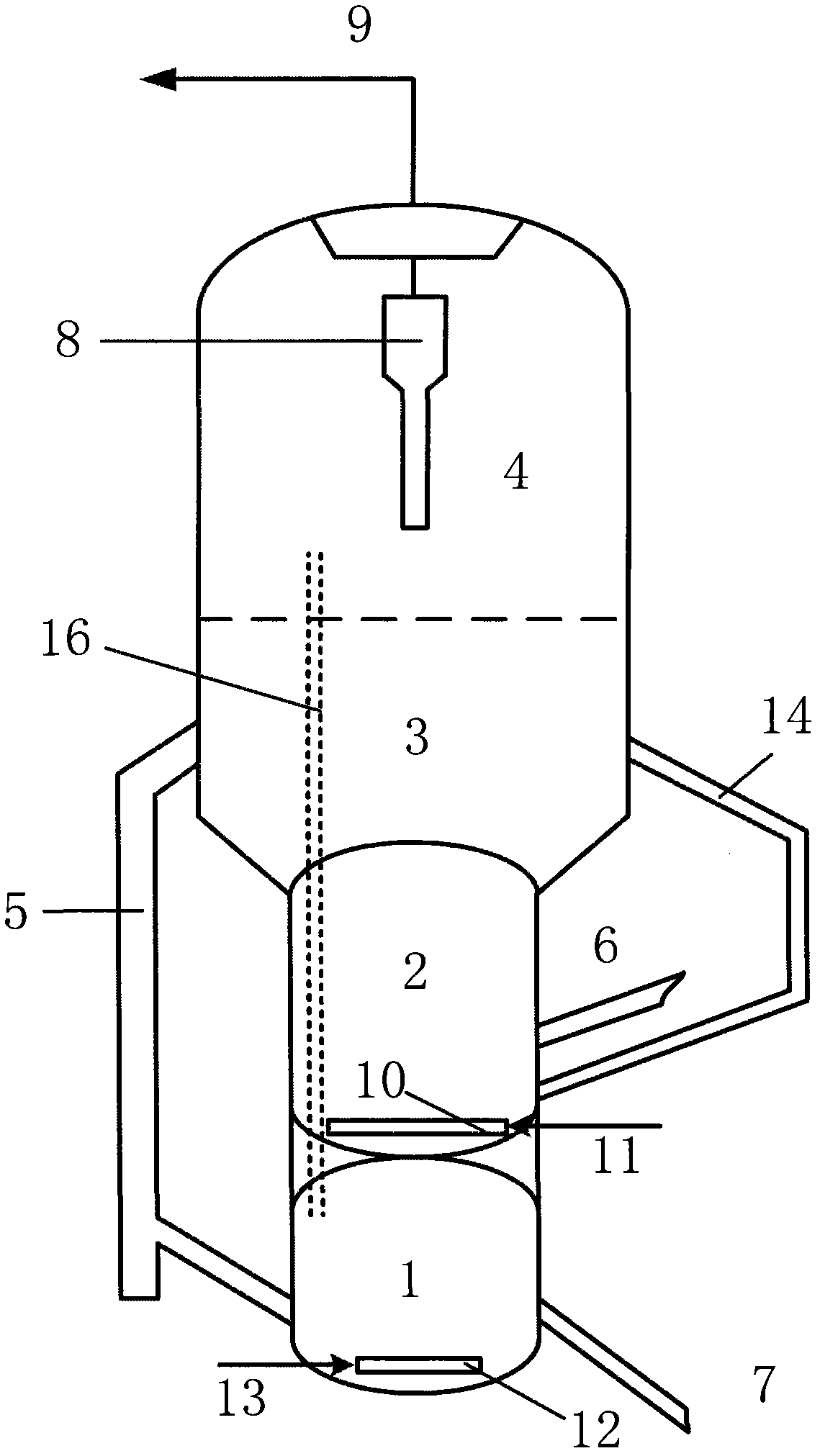

[0039] figure 2 It is a schematic diagram of the basic equipment of the second embodiment provided by the present invention.

[0040] Such as figure 2 As shown, the buffer zone 1, the regeneration zone 2, the regeneration zone 3, and the settlement zone 4 are arranged vertically from bottom to top. The cooling zone 5 is juxtaposed between the regeneration zone 2, the regeneration zone 3 and the buffer zone 1. The regeneration zones 2 and 3 are With the coke tank regeneration method, the regeneration zone 3 and the settlement zone 4 adopt the method of direct connection to the wall. The spent catalyst from the reactor enters the bottom of the coke-tank regeneration zone 2 through the spent inclined pipe 6 and is mixed with the high temperature catalyst returned by the circulating pipe 14 to increase the temperature of the spent catalyst. The main air flows from the main air distribution plate 10 through the pipeline 11 The bottom of the coking tank regeneration zone 2 enters. Af...

Embodiment approach 3

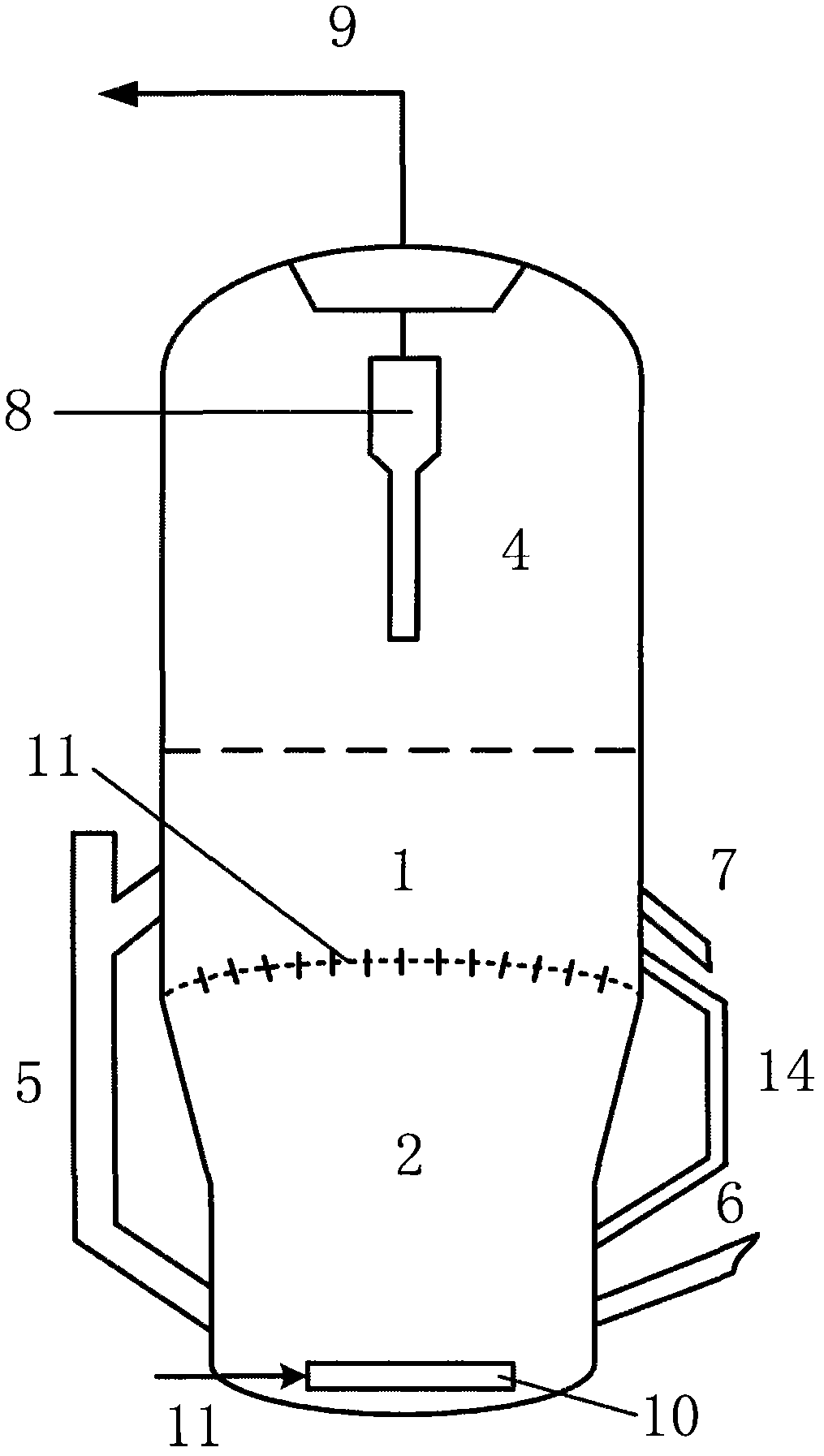

[0042] image 3 It is a schematic diagram of the basic equipment of the third embodiment of the present invention.

[0043] Such as image 3 As shown, the regeneration zone 2, the buffer zone 1 and the settlement zone 4 are arranged vertically from bottom to top. The cooling zone 4 is juxtaposed between the regeneration zone 2 and the buffer zone 1. The regeneration zone 2 is a single-stage regeneration method, and the buffer zone 1 and the settlement zone Zone 4 adopts direct connection to the vessel wall. The standby catalyst from the reactor enters the regeneration zone 2 through the standby inclined pipe 6 and is evenly distributed on the upper part of the dense phase bed through the distributor. The main air enters from the bottom of the regeneration zone 2 through the pipeline 11 from the main air distribution plate 10 and flows upward. The coke combustion reaction occurs when the catalyst is in countercurrent contact with the spent catalyst flowing downward by gravity. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com