Method for managing drilling components such as drill pipes, drilling tools, drilling casings

A technology of drilling tools and components, which is applied to drill pipes, casings, and automatic control systems for drilling, and can solve problems such as time increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

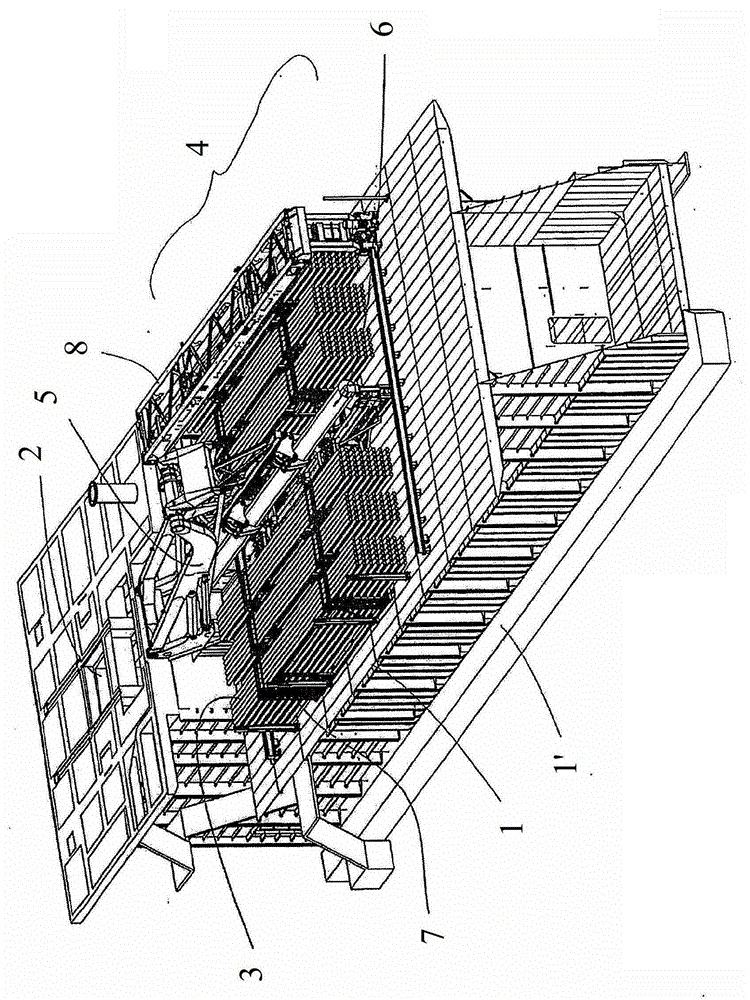

[0042] figure 1 is a perspective view of part of an offshore drilling platform. It consists of two cover plates 1, 1' of a drilling platform provided with openings 2 for (not shown) drill pipes through which drilling is carried out vertically downwards through the water . For this, a drilling mast (not shown) with support and guide elements and a drive for the drill rods are used via the opening 2 . On the upper cover plate 1 of the drilling platform, a plurality of drill pipes 3 are placed in an automatic storage rack 4 . In the storage rack 4, the drill pipe 3 is placed in a horizontal orientation. The drill pipe manipulator 5 is used to adjust the drill pipe 3 one by one from the horizontal ready position 6 to a vertical position above the opening 2 so that it can be fed by the borehole to another (not shown) of the device. The element is lowered into the borehole through the opening 2 .

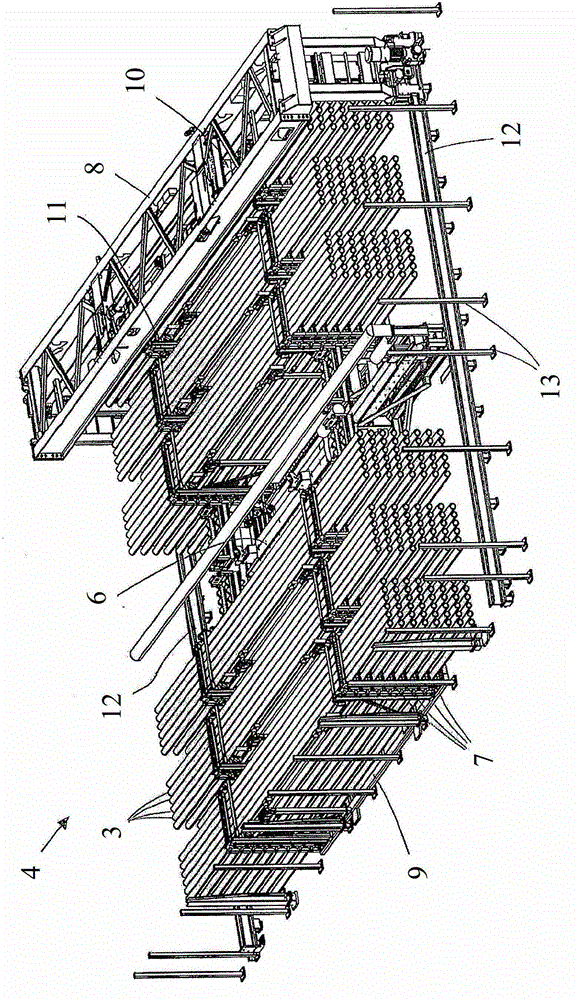

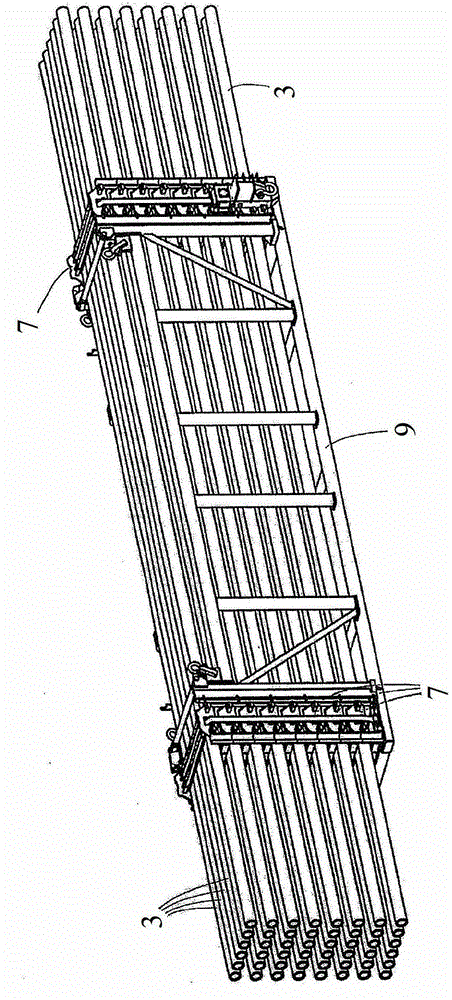

[0043] exist figure 2 The storage rack 4 used as a storage, introduction and p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap