Tension type magneto-rheological buffer,

A magnetorheological buffer and magnetorheological technology, applied in the field of buffering, can solve the problems of small damping force adjustment range, small damping force, and short effective length of damping channel, so as to achieve the effect of increasing the effective length and meeting the buffering requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

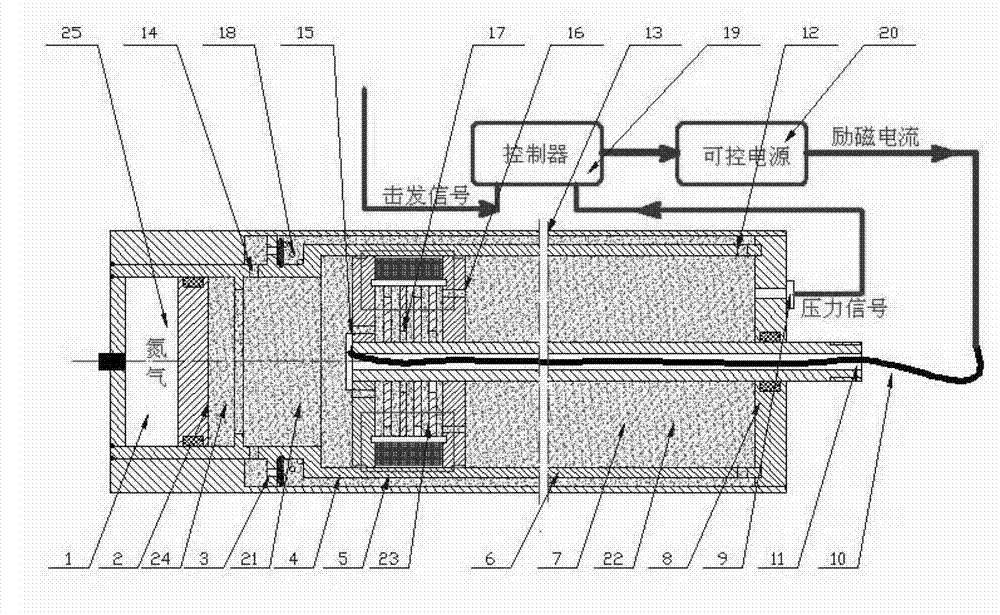

[0021] Please refer to figure 1 , is a schematic structural view of an embodiment of the stretched magneto-rheological damper of the present invention. It includes: working cylinder I6, piston I4 and piston rod 11.

[0022] Wherein, the piston I4 is arranged in the working cylinder I6, and the working cylinder I6 is divided into a chamber I21 and a chamber II22. One end of the piston rod 11 is fixed on the piston I4, and the other end passes through the chamber II22 and extends out of the working cylinder I6.

[0023] In the above structure, the excitation coil 5 and the multi-stage radial damping channels 23 are arranged on the piston I4. Specifically, there is an oil chamber inside the piston I4, and the two ends of the oil chamber communicate with the chamber I21 and the chamber II22 through the oil outlet holes (left oil outlet 15, right oil outlet 16), and the inside of the oil chamber is covered by multiple pieces. The separation plate 17 is divided into multi-stage ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com