Laser gyroscope offset frequency method based on external cavity feedback

A laser gyro and frequency bias technology, applied in the field of laser gyro, can solve the problems of increasing cavity loss, coating, and too harsh cavity adjustment, and achieve the effects of eliminating mechanical noise, reducing system complexity, and improving measurement bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation will be described below in conjunction with the accompanying drawings.

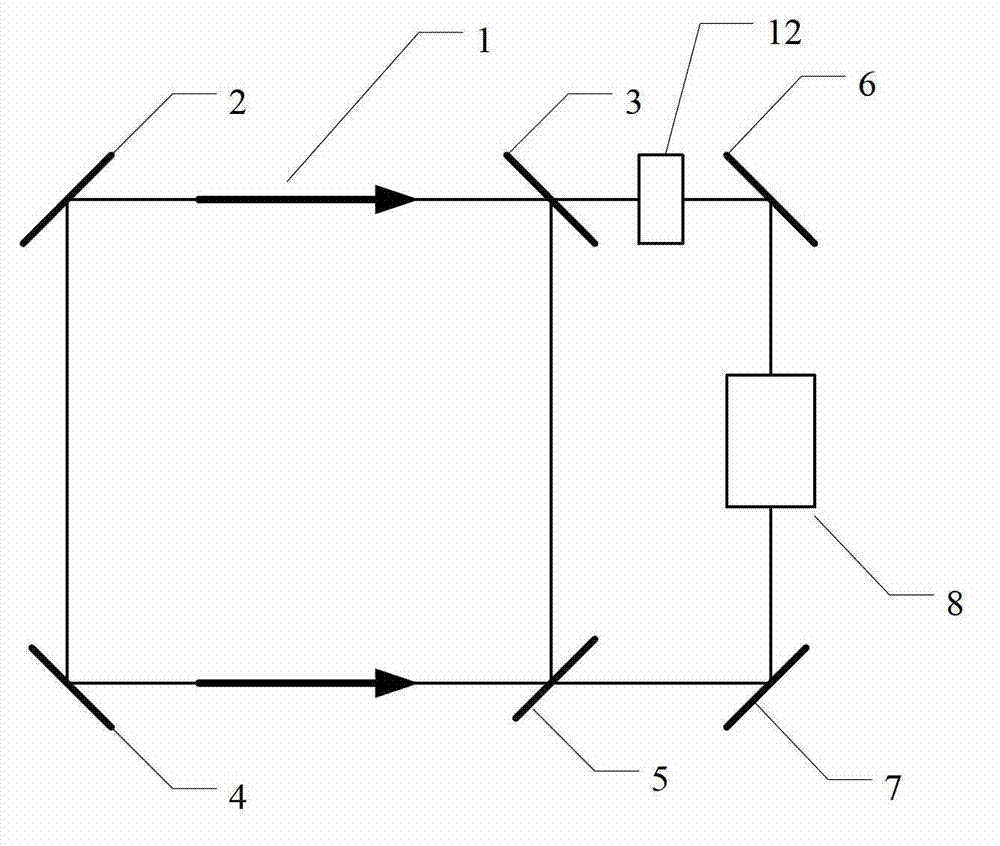

[0030] figure 1 It is a schematic diagram of laser gyro frequency bias based on external cavity feedback, which includes a laser gyro 1 and a fifth mirror 6, a sixth mirror 7, a path length modulation device 12, a non-reciprocal optical device 8, a mirror II 3 and a mirror Feedback external cavity composed of IV5, wherein the laser gyro 1 is composed of reflector I2, reflector II3, reflector III4, and reflector IV5. The laser light transmitted from the reflector II3 is redirected by the fifth reflector 6 and the sixth reflector 7 in the external cavity, and enters the laser gyro resonator from the reflector IV5 again. Similarly, the laser light transmitted from the reflector IV5 passes through the Ⅱ3 re-enters the laser gyro cavity. Due to the feedback of the external cavity, a frequency difference is added between the clockwise and counterclockwise light waves in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com