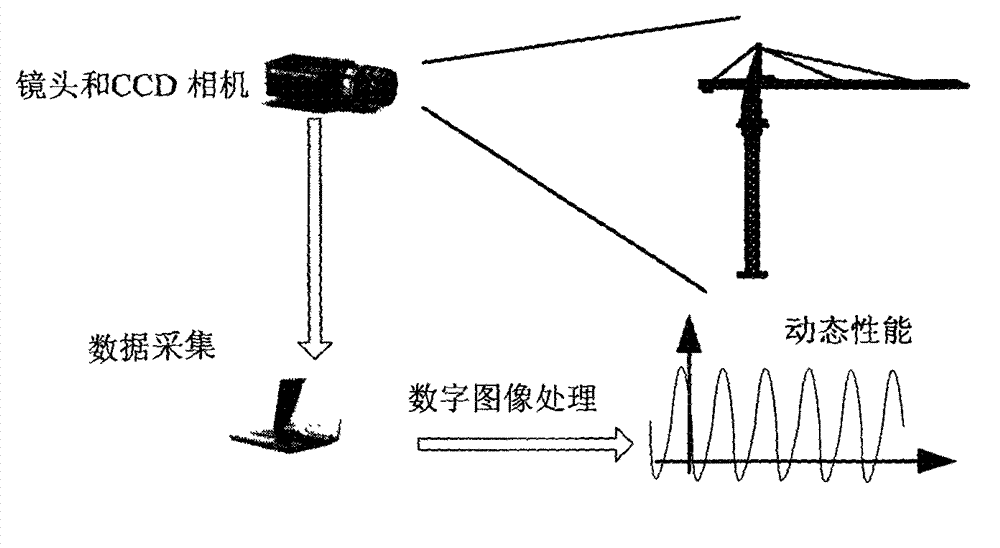

Non-contact vibration detecting method of tower crane structure

A tower crane and vibration detection technology, applied in the field of detection, can solve problems such as powerlessness, complicated installation and use, and limited number of measurement points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

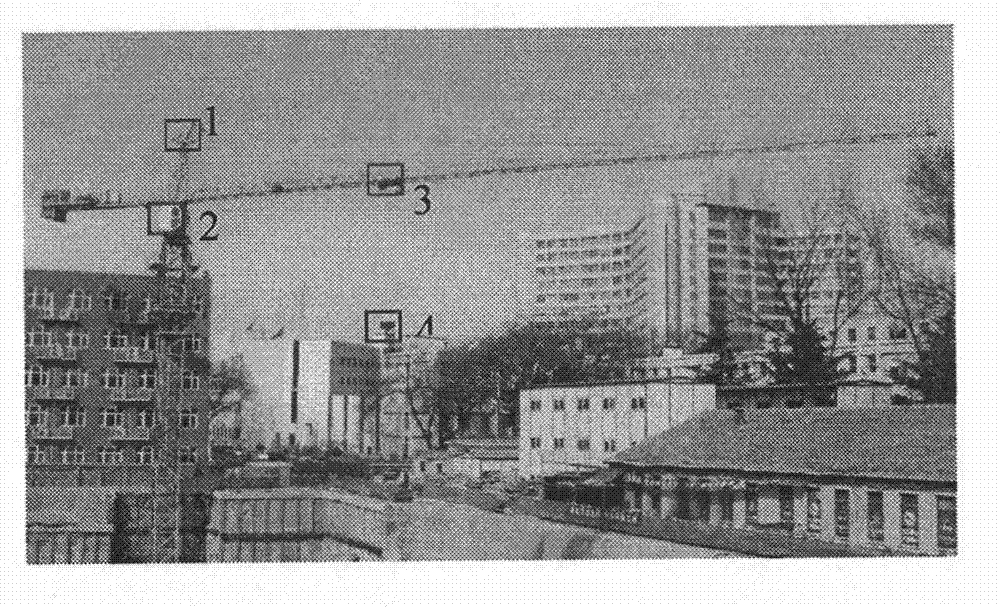

[0064] In order to better illustrate the purpose and advantages of the present invention, the technical solution will be further described below in conjunction with the accompanying drawings and embodiments.

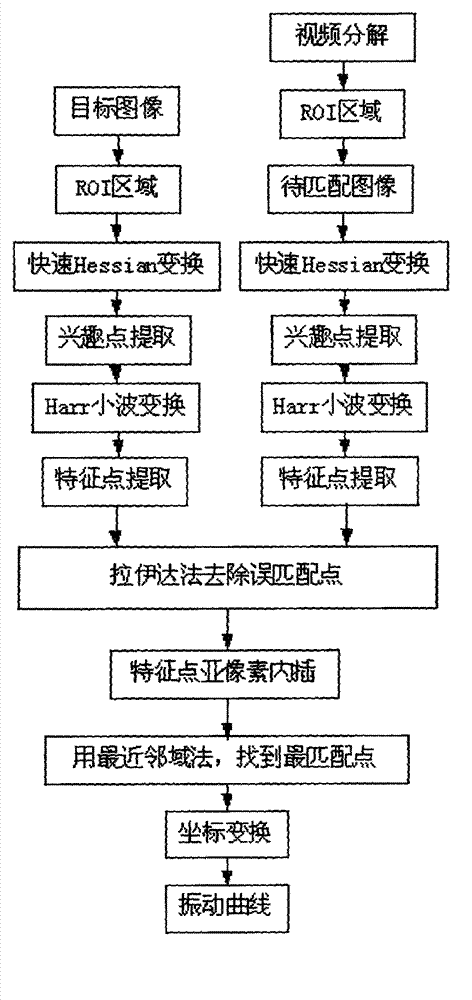

[0065] ●Algorithms for image processing

[0066]The method of the present invention uses a SURF algorithm based on ROI (Regions of Interest) technology, which can reduce the image tracking area and reduce the amount of calculation, and can also achieve higher sub-pixel precision. Secondly, fast Hessian transformation is performed on the ROI image decomposed from the video and the ROI area of the target image, and then the obtained interest points are matched.

[0067] The SURF feature matching algorithm uses the nearest neighbor vector matching algorithm. This algorithm uses the Euclidean distance of the key point feature vector as the similarity measure. Let N 1 and N 2 are the SURF feature point sets of images P and Q respectively, for N 1 Any feature point p in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com