Method for preparing intermediate and long infrared undercut type optical waveguides based on silicon on insulator (SOI) materials

A long-infrared and optical waveguide technology, applied in light guides, optics, optical components, etc., can solve the problems of mode leakage, high silicon dioxide loss, and limited light field, etc., and achieve low transmission loss, easy purchase, and flexible design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0029] 1. Cleavage the SOI sheet into the desired size, clean and dry according to the standard cleaning process, and clean the photolithography plate at the same time;

[0030] 2. Put the SOI sheet into the thermal oxidation furnace, alternately perform dry oxygen and wet oxygen twice, so that it grows a dense oxide layer with a thickness of about 600nm;

[0031] 3. Spin-coat the photoresist with a coating machine and pre-bake it for 30 minutes, then use a photolithography machine to transfer the waveguide pattern on the photoresist board to the SOI sheet, develop, shape, post-bake, and harden the film;

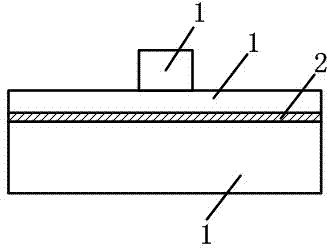

[0032] 4. Etch the waveguide on the upper surface silicon 1 by dry etching or wet etching process, such as figure 1 , figure 2 shown;

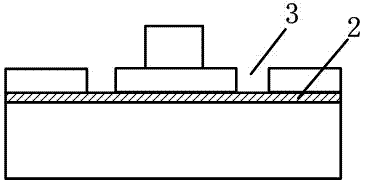

[0033] 5. Clean the SOI sheet again, put it into a thermal oxidation furnace for secondary oxidation to prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com