High-precision silver grid line screen production method for crystalline silicon solar cells

A solar cell and manufacturing method technology, which is applied to circuits, electrical components, photolithography process exposure devices, etc., can solve the problems of the decline of cell quality and electrical properties, incomplete development, network blocking, etc., and achieve high aspect ratio. Fine line printing, eliminating the network knot in the ink penetration area, and avoiding the effect of low ink penetration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

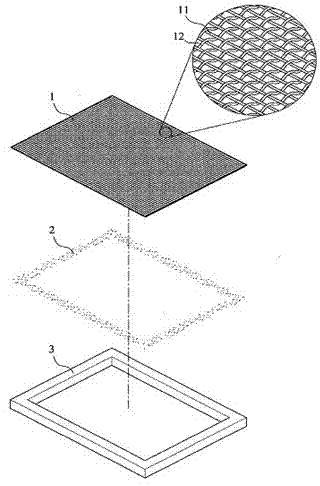

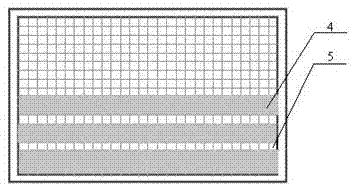

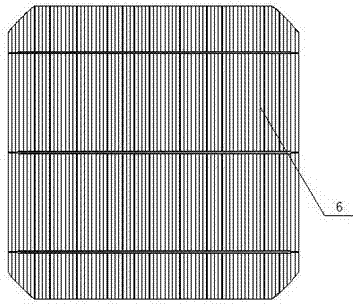

[0019] Such as figure 1 As shown, the screen plate of this high-definition positive silver grid line screen production method for crystalline silicon solar cells consists of a screen cloth 1, an adhesive 2, a screen frame 3, a photosensitive adhesive 4, an ink-permeable area 5, a grid line 6, and a warp line 11 And these components of weft 12 are formed.

[0020] The manufacturing steps of the method for manufacturing the high-definition front-side silver screen for crystalline silicon solar cells are as follows:

[0021] In the first step, a mesh cloth 1 is formed by weaving a plurality of warp threads 11 and weft threads 12, each warp thread and weft thread are respectively parallel to or perpendicular to the screen frame 3, and an adhesive 2 is applied to the surrounding area of the mesh cloth 1 to tighten the mesh cloth 1 Finally, it is fixed on the inner side of the screen frame 3 to form a screen;

[0022] In the second step, degreasing treatment and roughening treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com