Distribution transformer cover plate

A distribution transformer and cover plate technology, which is applied in the manufacture of inductors/transformers/magnets, transformer/inductor shells, circuits, etc., can solve the problems of large ship shape and wave deformation of the cover plate, increased plate thickness, and oil leakage. , to achieve the effect of small deformation of ship shape and wave, increase the thickness of steel plate, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

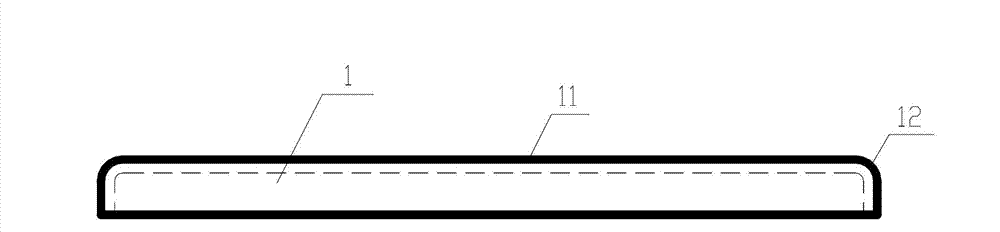

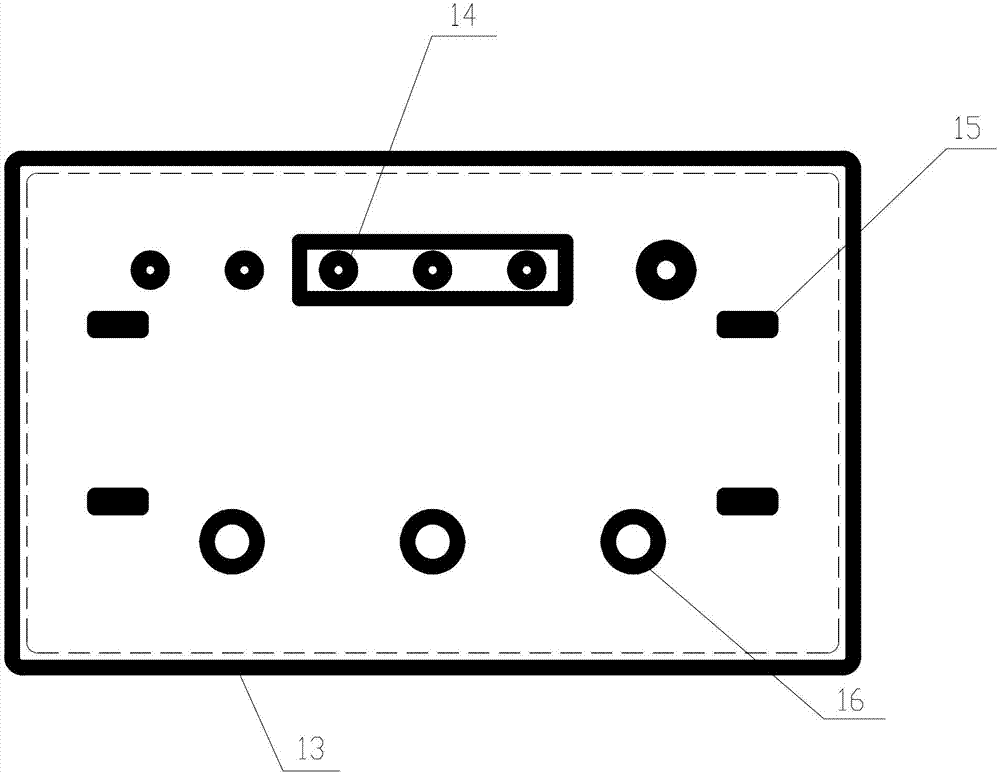

[0018] Such as figure 1 , figure 2 As shown, a distribution transformer cover plate includes a square cover plate body 1, the upper cover surface 11 of the cover plate body 1 is a flat end surface, and each of the four sides of the cover plate body 1 is extended by 60 mm as ribs 13. The four corners of the side 13 are respectively provided with a gap 12, and the front 30mm of the four ribs 13 are bent inwardly to 90° to form an edge, and the gap 12 is a gap of 30mm×30mm.

[0019] The process steps of preparing the cover plate of the present invention are as follows,

[0020] First, prepare the main body 1 of the cover plate by cutting the material according to the size of the cover plate drawing ----- punch out 30mm×30mm gaps at the four corn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com