Grinding fixture for diamond drilling tools

A diamond drill and knife grinding technology, which is applied in the field of mechanical processing fixtures, can solve the problems of inconvenient grinding amount, inaccurate indexing, eccentricity of tool tip, etc., and achieve the effects of high processing production efficiency, improved product quality, and improved concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

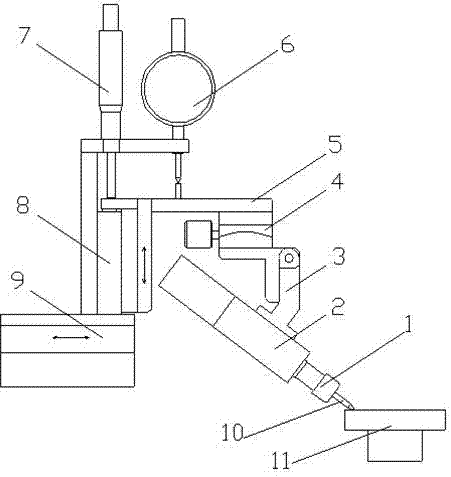

[0012] A diamond drill grinding jig, which includes a spring chuck 1, a stepping motor 2, a connecting rod 3, an arc-shaped slide rail 4, a slider cylinder 8, a dial indicator 6, a feed screw 7 and a slide table 9 , the collet 1 holding the diamond drill bit 10 to be ground is fixed at one end of the stepper motor 2 of its driving device, and the stepper motor 2 is connected below the curved slide rail 4 through the connecting rod 3, forming a collet In the inclined position with the end facing down, the curved slide rail 3 is installed under the extended end of the cantilever 5 of the slider cylinder, and the feed screw 7 is installed above the slider cylinder 8, and the feed screw 7 is connected to the slider cylinder 8. Cooperate to adjust the height of the diamond drill bit 10 to be ground, the slide block cylinder 8 is fixed on the slide table 9, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com