Winding and switching control system for wide lead tape production line

A control system and production line technology, applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of shortened service life of winding device devices, irregular lead coils, deformation, etc., to improve production efficiency , Eliminate the effect of accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

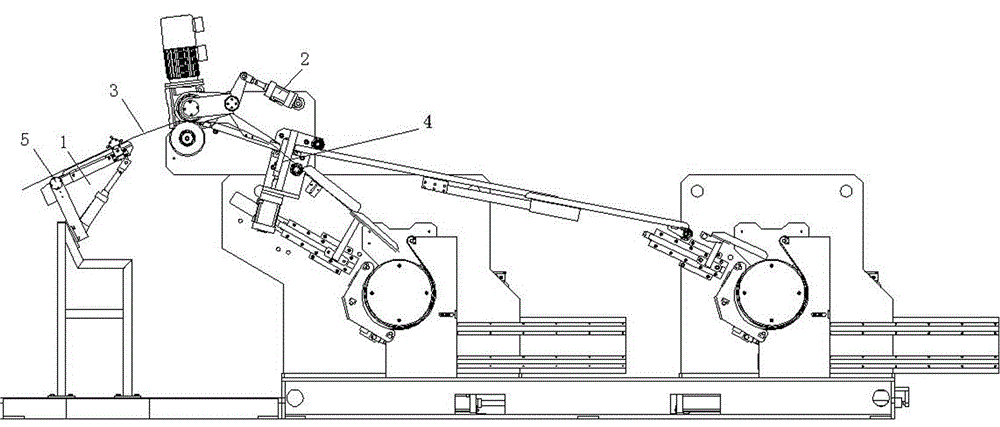

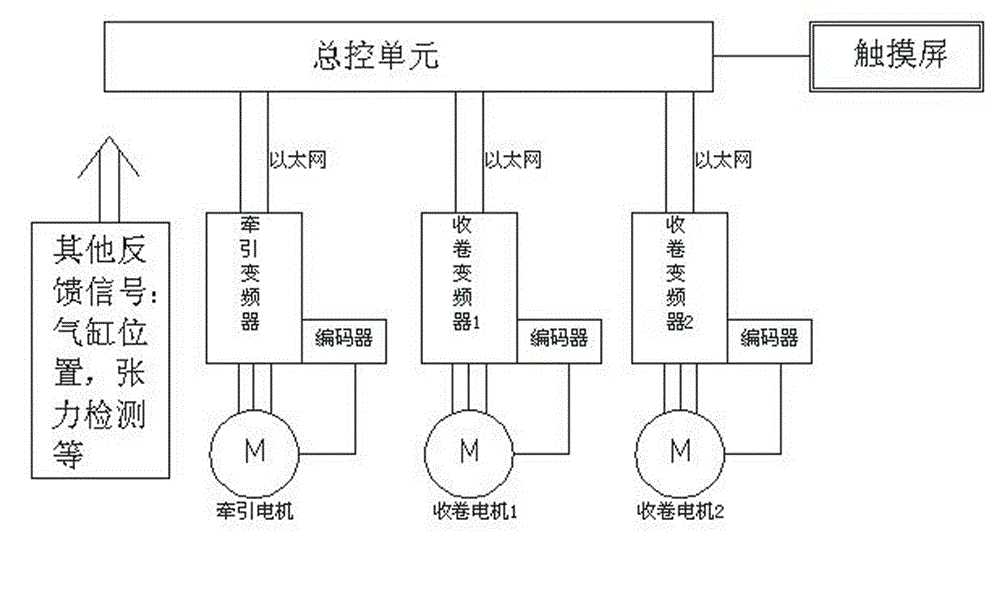

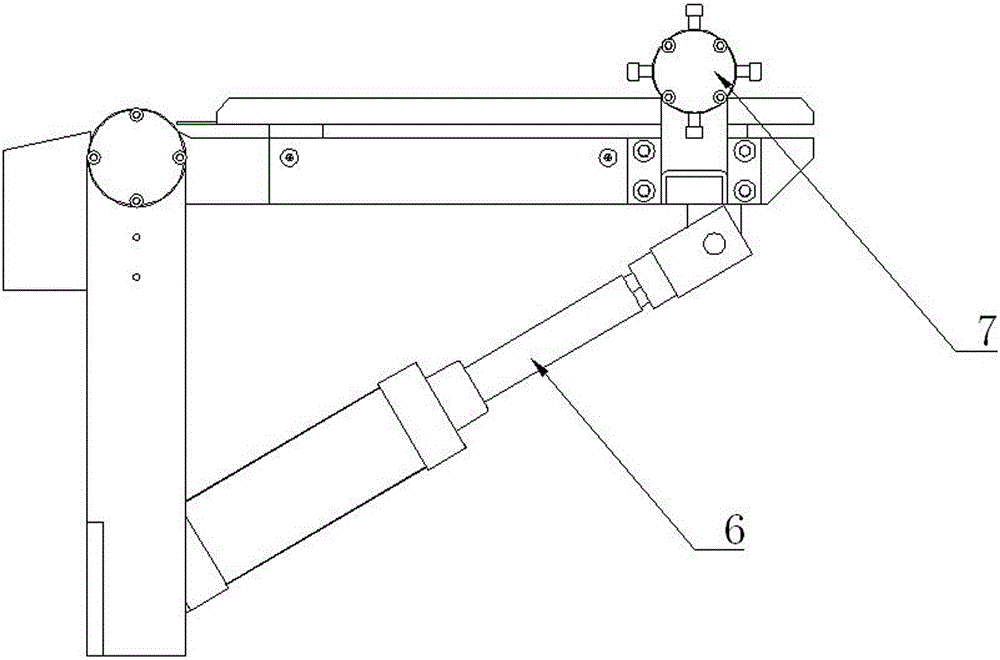

[0023] Such as figure 1 -Shown in -5, a kind of wide lead strip production line rewinding switch control system of the present invention is arranged after the tape feeding device, including PLC control system, tape cutting and lane changing device, for receiving the winding of the tape feeding device conveying the lead tape device, the rewinding device includes two rewinding passages, two rewinding rollers connected with their respective rewinding passages and two rewinding motors respectively connected with their respective rewinding rollers, and the rewinding switching control of the wide lead strip production line The system also includes a buffer mechanism 1 arranged between the tape feeding device and the winding device. The buffer mechanism 1 includes an angle sensor 5, a cylinder 6, a first pallet, a second pallet and a pinch shaft 7. The buffer mechanism 1 as a whole is Triangular, two supporting plates respectively constitute the two sides of the triangle, the cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com