Method for preparing mineral wool

A mineral wool and silk-making technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of polluting the environment, increasing the production cost of rock wool, consuming large coke, etc., and achieve good quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

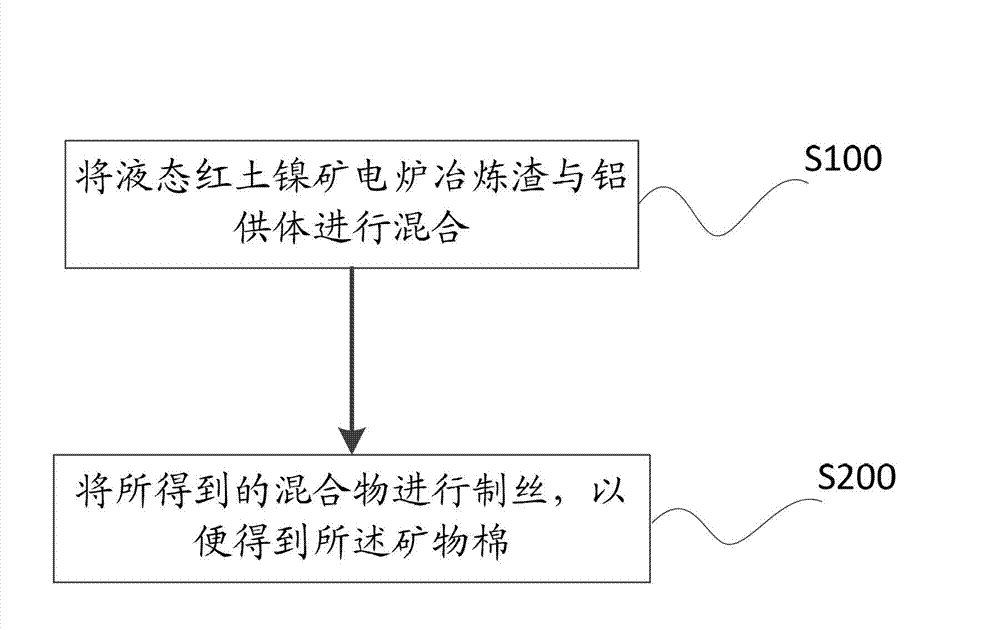

Method used

Image

Examples

Embodiment

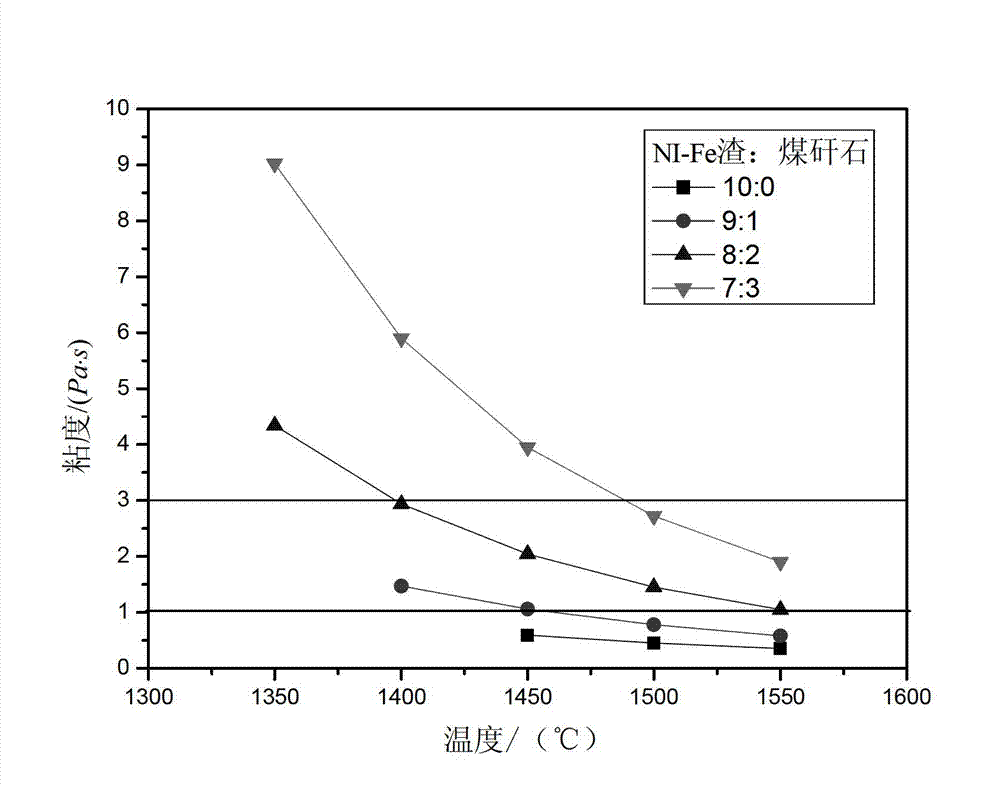

[0034] Table 1 Calculation results of ingredients

[0035] Ratio of ferronickel slag

CaO

MgO

SiO 2

al 2 o 3

Na 2 o

FeO

Fe 2 o 3

100.00

0.63

30.50

52.70

2.79

0.08

7.62

5.69

90.00

0.97

27.55

54.11

5.03

0.16

6.86

5.32

80.00

1.30

24.59

55.53

7.27

0.25

6.10

4.96

70.00

1.64

21.64

56.94

9.51

0.34

5.33

4.60

60.00

1.98

18.69

58.35

11.75

0.43

4.57

4.23

50.00

2.31

15.73

59.76

13.99

0.52

3.81

3.87

40.00

2.65

12.78

61.18

16.22

0.61

3.05

3.51

30.00

2.99

9.83

62.59

18.46

0.70

2.29

3.15

20.00

3.32

6.87

64.00

20.70

0.79

1.52

2.78

10.00

3.66

3.92

65.42

22.94

0.88

0.76

2.42

0.00

4.00

0.97

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com