Anhydrous stemming for tapping hole of blast furnace and preparation method thereof

A technology of blast furnace tapping and waterless taphole mud, which is applied in the field of blast furnace taphole mud and its preparation, can solve the problems of high cost and increased production cost, and achieve long tapping time, improved bonding, and iron slag resistance Good flushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

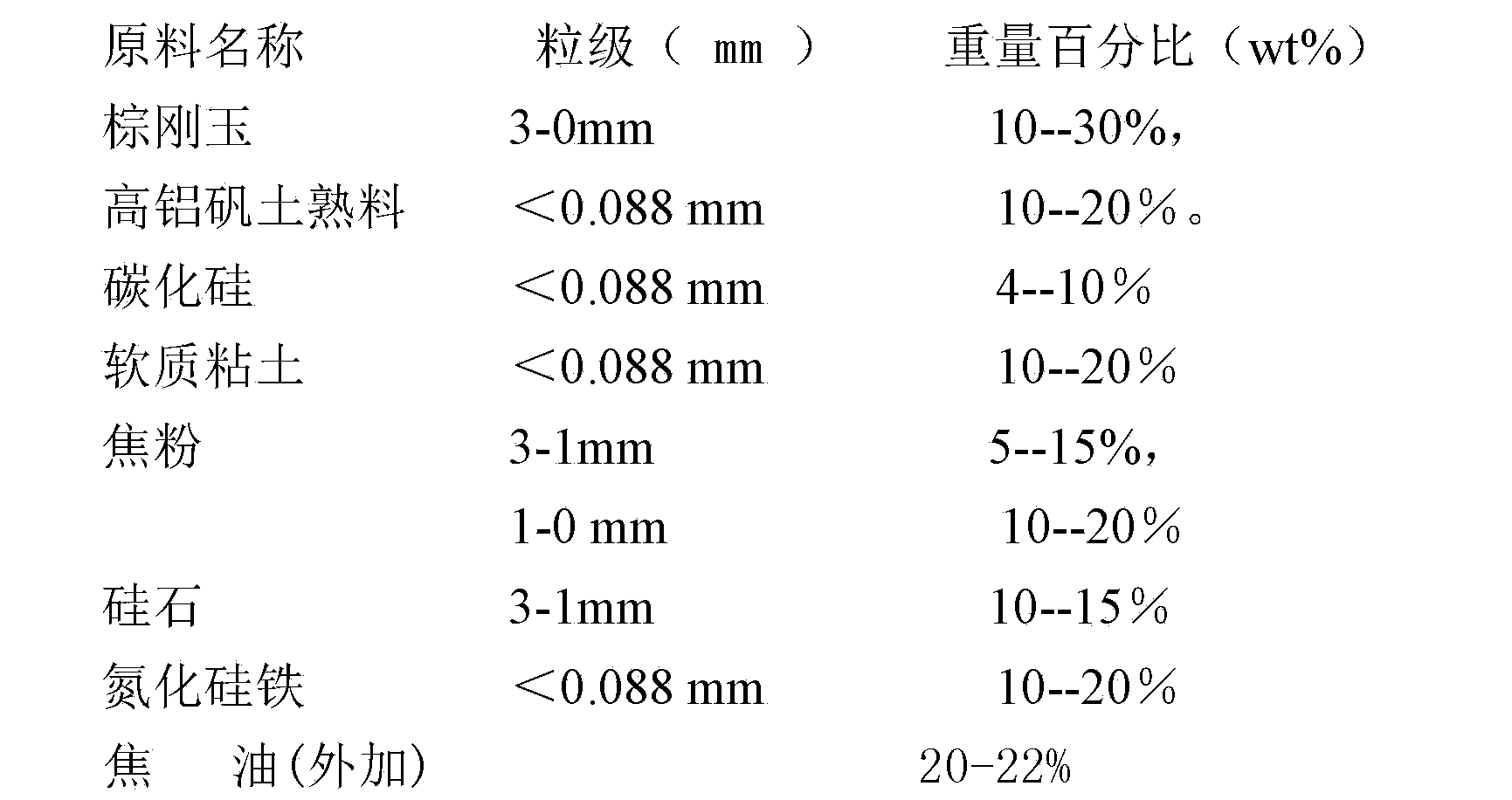

[0012] A kind of anhydrous taphole mud for blast furnace taphole, its raw material composition is by weight percentage:

[0013]

[0014] A kind of preparation method of anhydrous taphole mud for blast furnace taphole is as follows:

[0015] (a) Weigh various raw materials according to the ratio and pour them into the heating wheel mill, dry mix for 20 minutes, then add hot tar (oil temperature 80°C), control the temperature in the mill at 70-80°C, and wet mix for 40 minutes , and then measure the Mascia value of the mud at 50°C to 650-680KPa. If the Mascia value at 50°C of the mud does not meet the requirements of 650-680KPa, it is necessary to increase the mixing time or increase the amount of tar to continue adjusting until it meets the requirements.

[0016] (b) Put the qualified mud material obtained in step (a) into the mud extruder through the disc feeder and wrap it with plastic film to get the finished product. Put the finished mud into the hopper, After 48 hours,...

Embodiment 2

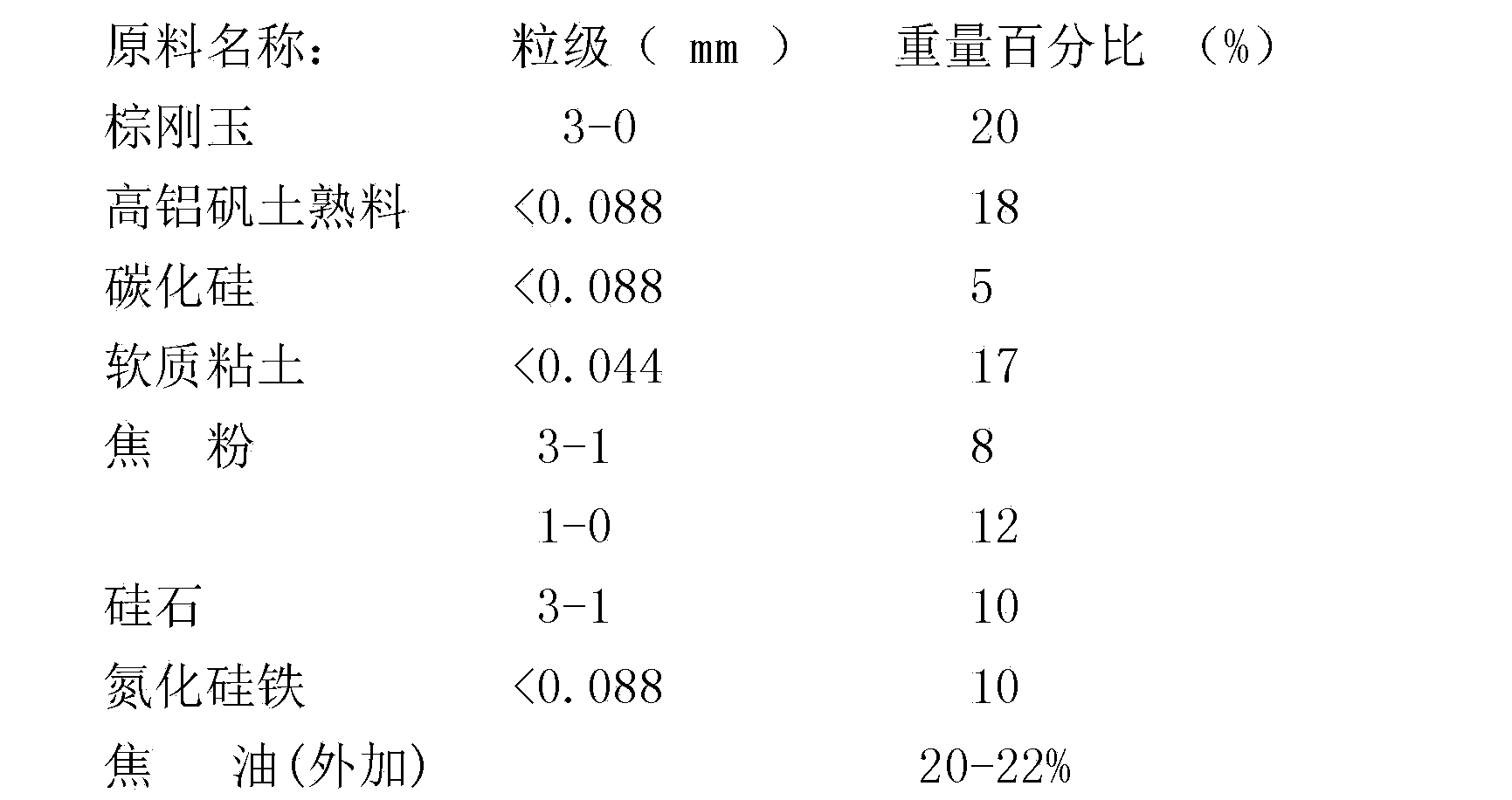

[0018] A kind of anhydrous taphole mud for blast furnace taphole, its raw material composition is by weight percentage:

[0019]

Embodiment 3

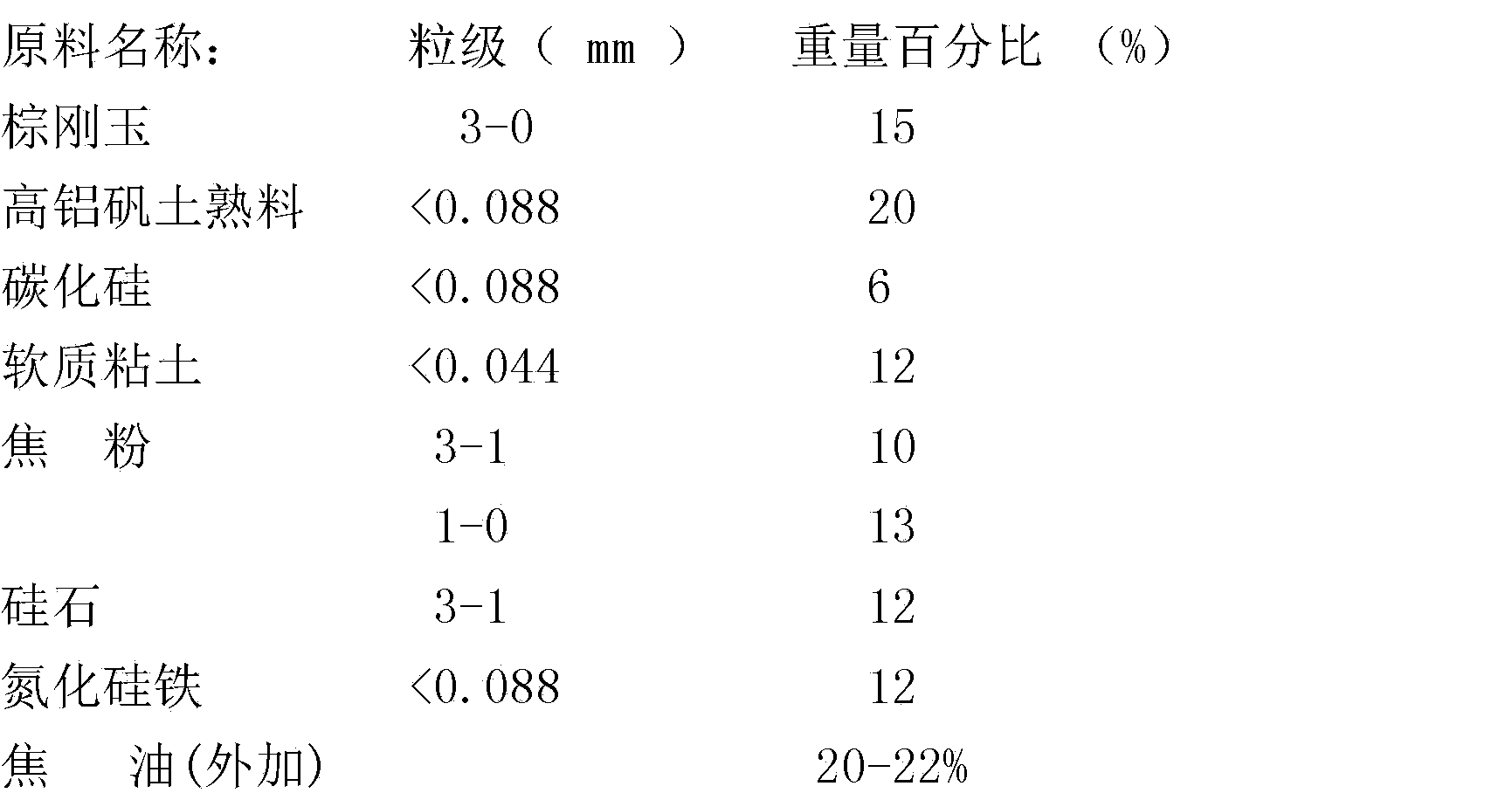

[0021] A kind of anhydrous taphole mud for blast furnace taphole, its raw material composition is by weight percentage:

[0022]

[0023] The method of embodiment 2 and embodiment 3 is identical with embodiment 1.

[0024] The invention has good resistance to iron slag scour, smooth tap hole channel, small change in aperture, excellent corrosion resistance, no splashing during tapping, long tapping time, suitable mud-drilling pressure and good opening performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com