Adhesion promoter and preparation method thereof

An adhesion promoter and organic solvent technology, applied in the field of adhesion promoter and its preparation, to achieve the effect of strong film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

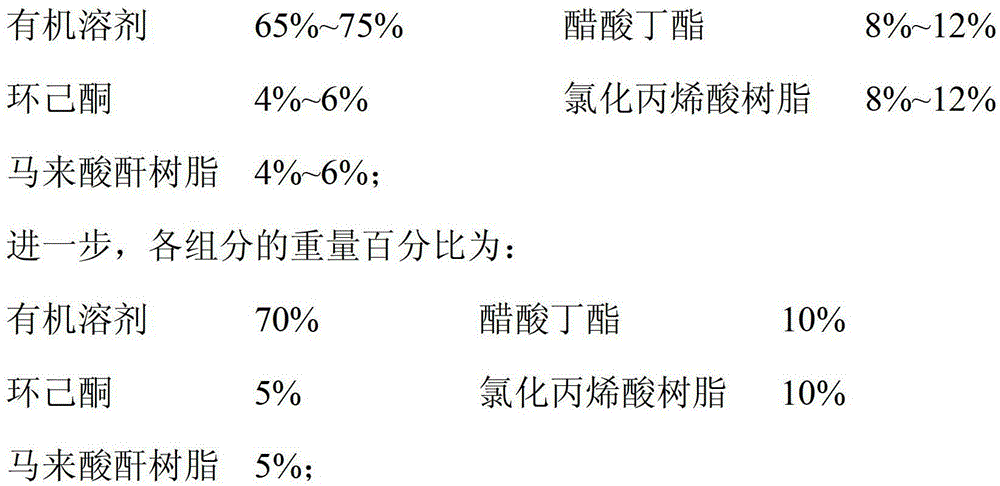

Method used

Image

Examples

Embodiment 1

[0018] (1) Mix and stir 70 kg of xylene, 10 kg of butyl acetate, and 5 kg of cyclohexanone until uniformly dispersed to obtain the raw materials of Group A;

[0019] (2) Mix 10 kg of chlorinated acrylic resin and 40% of Group A raw materials, stir until evenly dispersed, and obtain Group B raw materials;

[0020] (3) Mix and stir 5 kg of maleic anhydride resin and 35% of Group A raw materials, while raising the temperature to 60°C for 45 minutes to obtain Group C raw materials;

[0021] (4) In the remaining 25% of the raw materials of group A, add the raw materials of group B and group C in sequence, stir during the addition process, and adjust the temperature to 45°C for 30 minutes to obtain a golden yellow with A certain viscous liquid, that is, the finished product 1.

Embodiment 2

[0023] (1) Mix and stir 65 kg of xylene, 12 kg of butyl acetate, and 6 kg of cyclohexanone until uniformly dispersed to obtain the raw materials of Group A;

[0024] (2) Mix 11 kg of chlorinated acrylic resin and 45% of group A raw materials, stir until evenly dispersed, and obtain group B raw materials;

[0025] (3) Mix and stir 6 kg of maleic anhydride resin and 30% of Group A raw materials, while raising the temperature to 65°C for 50 minutes to obtain Group C raw materials;

[0026] (4) In the remaining 25% of the raw materials of group A, add the raw materials of group B and group C in sequence, stir during the addition process, and adjust the temperature to 48 ° C for 35 minutes to obtain a golden yellow with A certain viscous liquid, namely the finished product 2.

Embodiment 3

[0028] (1) Mix and stir 75 kg of xylene, 8 kg of butyl acetate, and 4 kg of cyclohexanone until uniformly dispersed to obtain the raw materials of Group A;

[0029] (2) Mix 9 kg of chlorinated acrylic resin and 35% of group A raw materials, stir until evenly dispersed, and obtain group B raw materials;

[0030] (3) Mix and stir 4 kg of maleic anhydride resin and 40% of Group A raw materials, while raising the temperature to 56°C for 55 minutes to obtain Group C raw materials;

[0031] (4) In the remaining 25% of the raw materials of group A, add the raw materials of group B and group C in sequence, stir during the addition process, and adjust the temperature to 42 ° C for 30 minutes to obtain a golden yellow with A certain viscous liquid, that is, the finished product 3.

[0032] We use the finished products 1, 2 and 3 obtained in Examples 1 to 3 for subsequent use, take 3 car bumpers, first use 200# solvent oil to thoroughly clean the surface of the car bumper, and then spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com