A kind of prechelated chitosan cementing cement slurry retarder and preparation method thereof

A technology for cementing cement slurry and chitosan, which is used in the field of downhole cementing slurry retarder and preparation, and the field of pre-chelated chitosan cementing cement slurry retarder and its preparation, which can solve the problem of limiting chitosan Application, flashing and thickening of cement slurry, etc., to achieve the effect of obvious right-angle thickening characteristics, low initial consistency, and solving the effect of flashing and thickening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 1.75g of chitosan with a degree of deacetylation of 92% and a particle size of 100-200 mesh and 2g of calcium hydroxide into 200g of water, stir, heat up to 70°C, chelate for 6 hours, cool to room temperature, and set aside. Code-named as sample 1.

Embodiment 2

[0025] Add 1.5g of chitosan with a degree of deacetylation of 92% and a particle size of 100-200 mesh and 1.5g of calcium hydroxide into 200g of water, stir, heat up to 65°C, chelate for 5 hours, cool to room temperature, and set aside. Code-named sample 2.

Embodiment 3

[0027] Add 2.0 g of chitosan with a degree of deacetylation of 92% and a particle size of 100 to 200 mesh and 2.5 g of calcium hydroxide into 200 g of water, stir, heat up to 75° C., chelate for 7 hours, cool to room temperature, and set aside. Code-named sample 3.

[0028] Evaluation of retarding performance of pre-chelated chitosan of the present invention:

[0029] Add a certain quality of water to the sample, and prepare cement slurry with a water-cement ratio of 0.44 according to the GB10238-88 standard. "Agent" was used to measure the thickening performance of the cement slurry added to the sample, and the results are shown in Table 1-3.

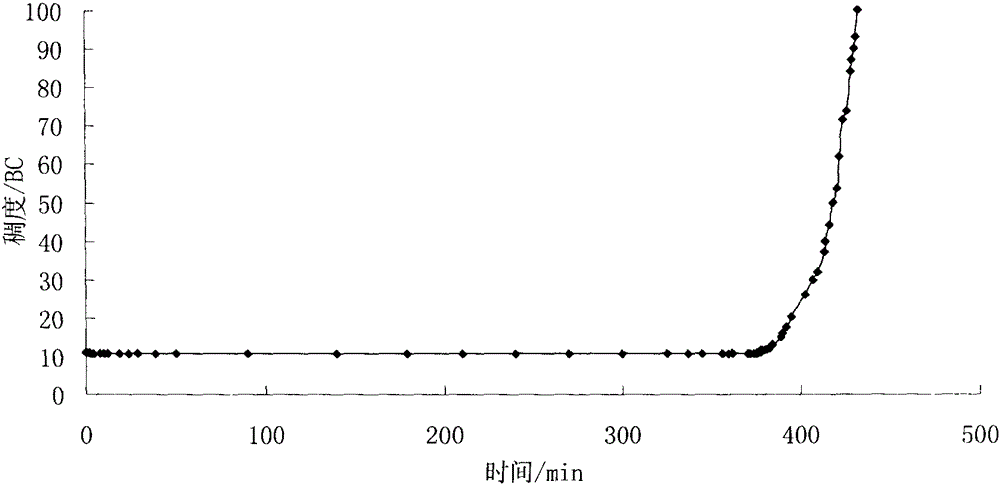

[0030] Table 1 Adding the cement slurry thickening performance of sample 1

[0031]

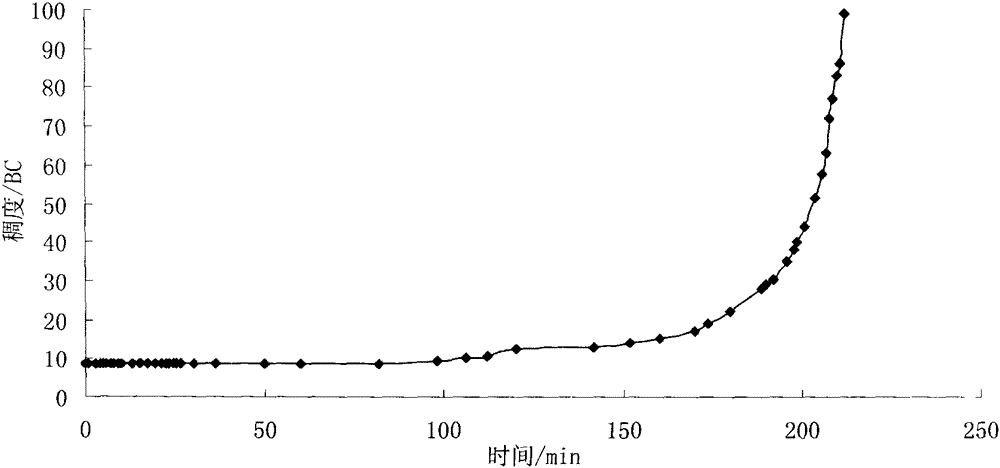

[0032] Table 2 Adding the cement slurry thickening performance of sample 2

[0033]

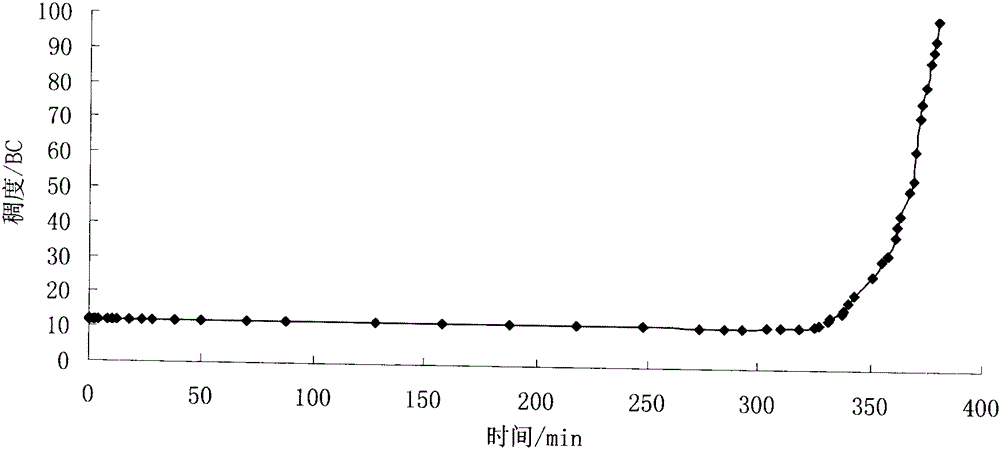

[0034] Table 3 Adding the cement slurry thickening performance of sample 3

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com