A kind of oil well cement fluid loss reducer and its preparation method and application

A fluid loss control agent, oil well cement technology, applied in chemical instruments and methods, drilling composition and other directions, can solve the problems of poor compatibility of admixtures, excessive retardation of cement slurry, delay of cement slurry thickening time, etc. Wide temperature range, improved temperature resistance, good thickening line shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

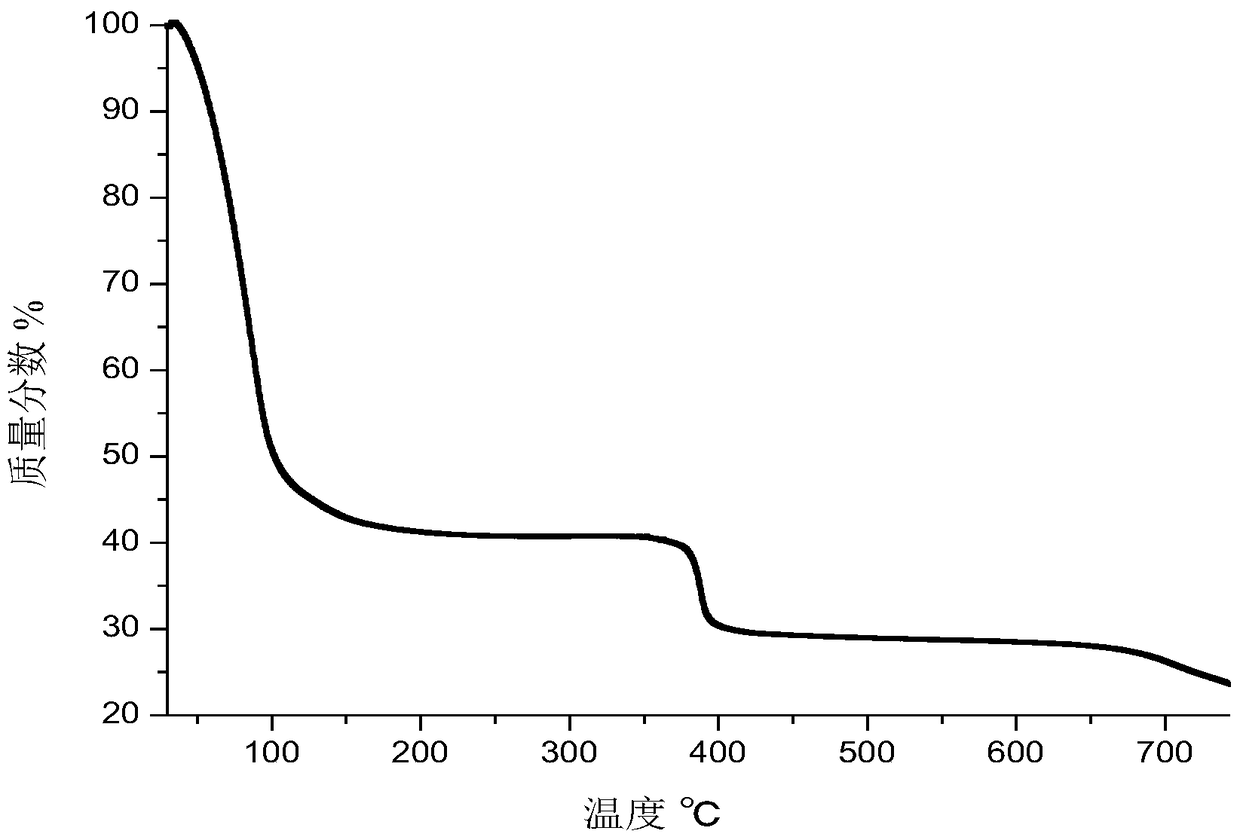

Image

Examples

Embodiment 1

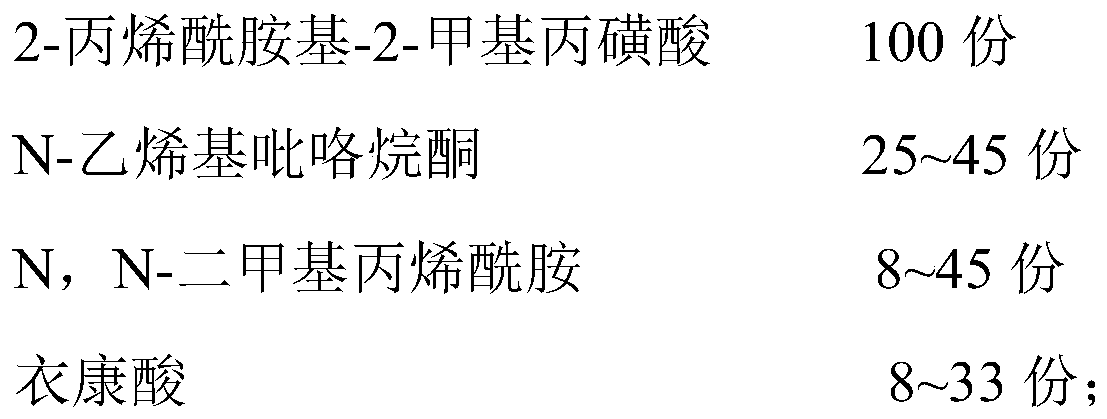

[0030] Example 1 Preparation of oil well cement fluid loss reducer of the present invention

[0031]Add 400kg of distilled water in the reactor, under the condition of stirring, add the weighed 62.4kg2-acrylamido-2-methylpropanesulfonic acid (AMPS), 18.7kg itaconic acid (IA) successively in the kettle, Use 20% sodium hydroxide solution to adjust the pH value of the solution in the kettle to 6.5, then add accurately metered monomer components 26.8kgN-vinylpyrrolidone (NVP) and 24.9kgN, N-dimethylacrylamide ( DMAM), the temperature of the solution in the kettle remains lower than 50°C during this process, and after stirring evenly, the pH value of the mixed solution in the kettle is adjusted to 7.5. Then, the temperature was raised until the temperature of the solution in the kettle rose to 55°C, and after 60 minutes of passing nitrogen gas, 26.5L of ammonium persulfate solution (50g / L) and 26.5L of sodium bisulfite solution (50g / L) were simultaneously added to the reaction kett...

Embodiment 2

[0032] Embodiment 2 Preparation of oil well cement fluid loss reducer of the present invention

[0033] Add 400kg of distilled water in the reaction kettle, under the condition of stirring, add weighed 89.3kg2-acrylamido-2-methylpropanesulfonic acid (AMPS), 8.9kg itaconic acid (IA) successively in the kettle, Use 20% sodium hydroxide solution to adjust the pH value of the solution in the kettle to 5.0, and keep the temperature of the solution in the kettle below 50°C. Then add accurately metered monomer components 24.1kgN-vinylpyrrolidone (NVP) and 13.4kgN, N-dimethylacrylamide (DMAM) into the kettle, the solution temperature in the kettle is kept below 50°C during this process, stir After uniformity, the pH value of the mixture in the kettle was adjusted to 6.0. Then, the temperature was raised until the temperature of the solution in the kettle rose to 50°C, and after passing nitrogen gas for 30 minutes, 13.3L ammonium persulfate solution (50g / L) and 13.3L sodium bisulfite ...

Embodiment 3

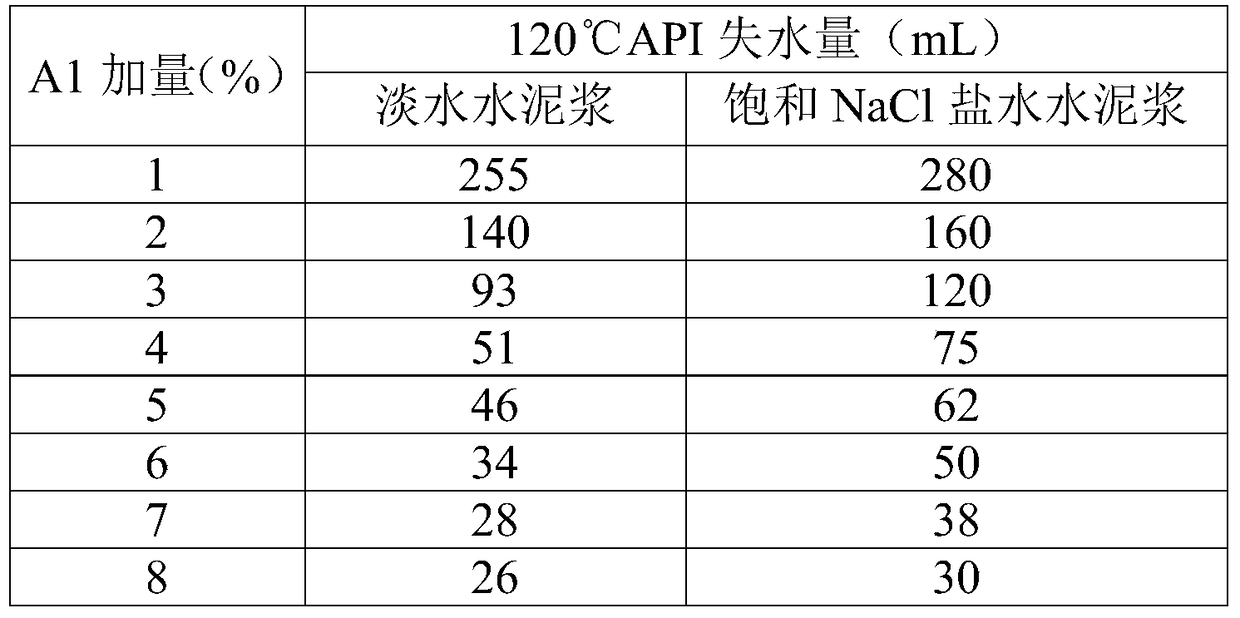

[0034] Example 3 Evaluation of fluid loss reducing performance of oil well cement fluid loss reducer product A1 of the present invention

[0035] According to the cement slurry formula (G grade cement + 35% silica fume + (1 ~ 8.0)% A1 + 44% tap water, calculated according to the weight percentage of cement) to test the water loss of fresh water cement slurry and saturated NaCl brine cement slurry, the test method is in accordance with GB / T 19139-2003 "Oil Well Cement Test", the measurement conditions are in accordance with the China Petroleum and Natural Gas Industry Standard SY / T 5504.2-2005 "Evaluation Method for Oil Well Cement Additives Part 2: Fluid Loss Control Agent" to test API loss at 120 °C The amount of water, the experimental results are shown in Table 1 below.

[0036] The dehydration performance of the product A1 of table 1 embodiment 1

[0037]

[0038] From the experimental results in Table 1, it can be seen that the water loss of freshwater cement slurry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com