Oil well cement dispersant and preparation method thereof

A technology of oil well cement and dispersant, which is applied in the field of cement dispersant and its preparation, which can solve the problems of poor cement adaptability, low service temperature, and intolerance to salt, and achieve a wide range of applicable temperature, improved fluidity, and salt tolerance. high performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

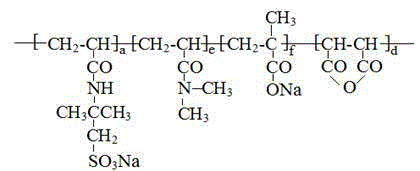

[0026] The preparation method of the described oil well cement dispersant comprises the following steps: adding alkenyl sulfonic acid, alkenyl amide, alkenyl carboxylic acid and alkenyl acid anhydride into a reaction kettle equipped with a solvent, adjusting the pH with alkali, and adjusting the reaction kettle Heating, adding an initiator, reacting for a period of time, terminating the reaction to obtain a liquid dispersant, drying and pulverizing the liquid dispersant to obtain a powdery solid dispersant.

[0027] Described solvent is water, and reactant weight accounts for the 15-25% of forming solution gross weight; Described polymerization initiator is a kind of in ammonium persulfate, potassium persulfate or benzoyl peroxide, and initiator addition is reaction 0.09-1% of the weight of the object.

[0028] The termination reaction is achieved by adding a terminator, sodium bisulfite, in an amount of 0.5-1.5% of the reactant weight.

[0029] The polymerization reaction te...

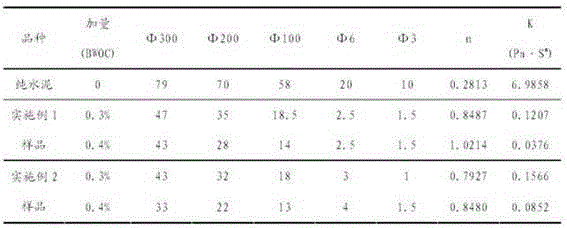

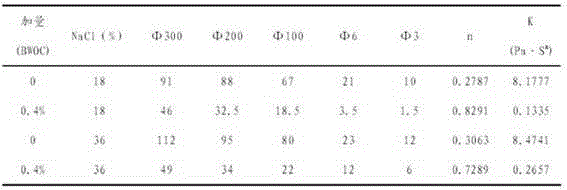

Embodiment 1

[0032] Take 150g of 2-acrylamido-2-methylpropanesulfonic acid, 65g of acrylamide, 5g of acrylic acid, 10g of maleic anhydride, and 800g of water, start stirring, add the four monomers into the water in turn, stir well and then add A certain amount of sodium hydroxide is used to adjust the pH of the solution to 6.0, heat while stirring, add 15g of ammonium persulfate solution with a mass concentration of 3% at a temperature of 75°C, continue to heat up to 84°C and then keep the temperature for 100 minutes to carry out polymer reaction , then add mass concentration and be 5% sodium bisulfite solution 35g, continue to stir for 30 minutes, reaction finishes, obtains pale yellow liquid dispersant, obtains solid powdery dispersant product after drying and pulverizing.

Embodiment 2

[0034] Take 150g of 2-acrylamido-2-methylpropanesulfonic acid, 68g of N,N-dimethylacrylamide, 5g of methacrylic acid, 20g of maleic anhydride, and 800g of water, and adjust the pH of the solution to 6.5. When the temperature is 70°C, 20 g of ammonium persulfate solution with a mass concentration of 3% is added.

[0035] Operate according to the method described in Example 1 to obtain the dispersant of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com