Nanocrystalline nucleus early-strength polyarylether water reducer mother liquor, and preparation method and compound liquid thereof

A polyarylene ether and early-strength technology, which is applied in the field of nanocrystalline core early-strength polyarylene ether water reducing agent mother liquor and its preparation method and compound liquid, can solve the problem of poor early-strength effect of cement and low durability of concrete. problems, to achieve the effect of high water reduction rate, reduced energy consumption and expenditure, and good concrete construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

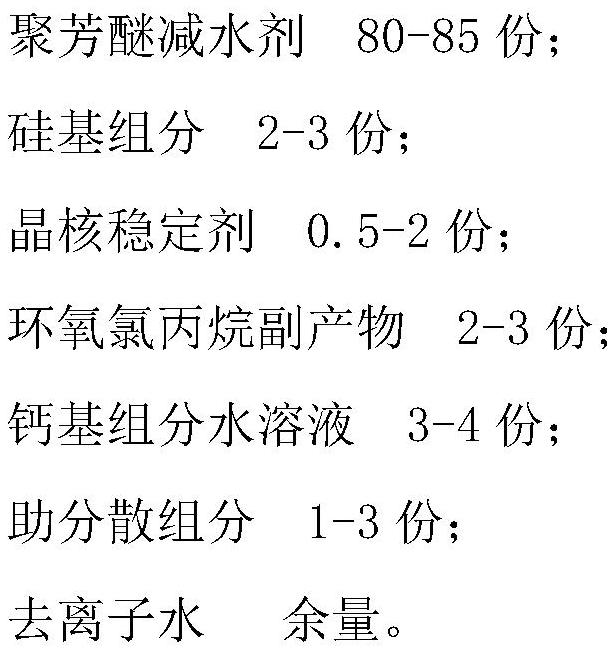

[0049](1) Preparation of mother liquor of nano-crystal core early-strength polyarylether water-reducer: at 30°C, mix 80 parts (parts by weight, the same below) of polyarylether water-reducer, 2 parts of sodium silicate, 0.5 part Sodium thiocyanate, 2 parts of epichlorohydrin by-products and 11.5 parts of deionized water are put into the reactor and stirred evenly, and the shear stirring speed is 3500r / min; Drop into the reactor for 10 minutes, then drop 1 part of the auxiliary dispersion component into the reactor for 5 minutes, and then increase the shear stirring speed to 6000r / min and continue shearing for 5 minutes to obtain the nanocrystalline core early-strength polyarylene Ether superplasticizer mother liquor.

[0050] (2) Preparation of compound solution (by weight): 20 parts of mother liquor of nano-crystal core early-strength polyarylether water reducer, 2 parts of epichlorohydrin by-product, 0.5 part of N,N-dimethyl Acetamide and 77.5 parts of deionized water are c...

Embodiment 2

[0060] (1) Preparation of mother liquor of nano-crystal core early-strength polyarylether water reducer: at 80°C, mix 85 parts (parts by weight, the same below) of polyarylether water reducer, 3 parts of potassium silicate, 2 parts Potassium thiocyanate and 3 parts of epichlorohydrin by-products were put into the reactor and stirred evenly, the shear stirring speed was 5000r / min, and 4 parts of calcium thiosulfate aqueous solution with a mass concentration of 25% were dropped into the reactor in 20min , and then drop 3 parts of dispersing components into the reactor in 10 minutes, and then increase the shear stirring speed to 7000r / min and continue shearing for 10 minutes to obtain the nano-crystalline core early-strength polyarylether water reducer mother liquor.

[0061] (2) Preparation of compound liquid (by weight): 30 parts of nano-crystal core early-strength polyarylether water reducer mother liquor, 3 parts of epichlorohydrin by-products, 2 parts of ammonium sulfate and...

Embodiment 3

[0071] (1) Preparation of mother liquor of nano-crystal core early-strength polyarylether water-reducer: at 50°C, 82 parts (parts by weight, the same below) of polyarylether water-reducer, 2.5 parts of sodium metasilicate, 1 Part of sodium sulfate, 2.5 parts of epichlorohydrin by-products and 6.5 parts of deionized water are put into the reactor and stirred evenly, and the shear stirring speed is 4000r / min, and 3.5 parts of mass concentration are 20% calcium thiosulfate aqueous solution in Drop into the reactor for 15 minutes, then drop 2 parts of the auxiliary dispersing components into the reactor for 8 minutes, and then increase the shear stirring speed to 6500r / min and continue shearing for 8 minutes to obtain the nanocrystalline core early-strength poly Aryl ether superplasticizer mother liquor.

[0072] (2) Preparation of compound solution (by weight): 25 parts of nano-crystal core early-strength polyarylether water reducer mother liquor, 2.5 parts of epichlorohydrin by-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com