Method for preparing bio-oil fuel from microalgae through thermo-chemical conversion

A technology of thermochemical conversion and bio-oil, applied in fuel, liquid carbon-containing fuel, petroleum industry, etc., can solve problems such as lack of research, achieve rapid growth, easy survival, and beneficial effects of governance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

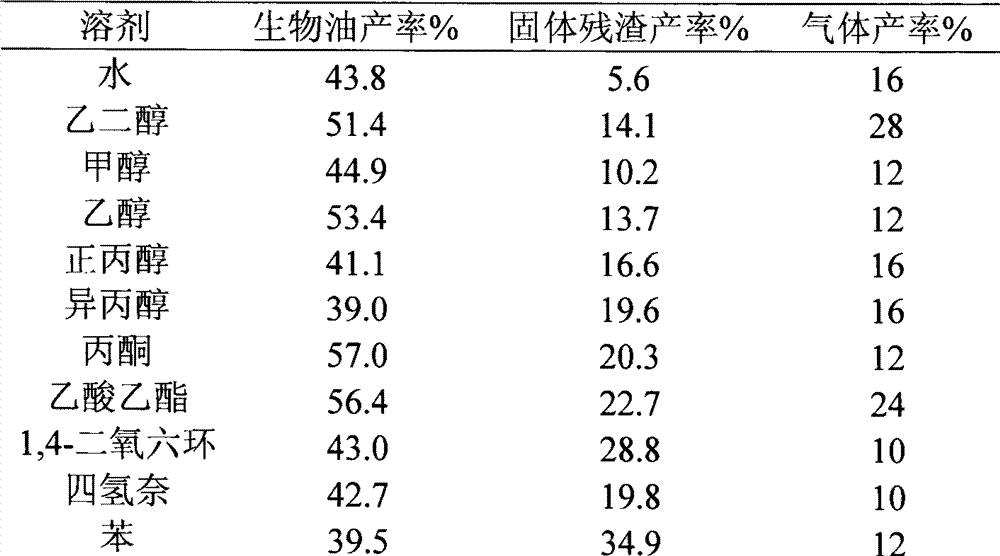

[0025] The dried microalgae is pulverized in a pulverizer to obtain microalgae fine particles. Weigh 2.5g of the treated microalgae, put it in a 60ml autoclave, add 4ml of water, without catalyst, and seal it. Put the autoclave into the molten salt, control the temperature at 350°C for 60min. After the reaction is completed, quickly cool with water, depressurize and weigh the gas mass, open the reactor, and collect the mixture in the reactor. The reaction mixture was extracted with dichloromethane, separated and filtered to obtain a solid residue and an organic phase, and the dichloromethane was removed by rotary evaporation to obtain bio-oil.

Embodiment 2

[0027] The dried microalgae is pulverized in a pulverizer to obtain microalgae fine particles. Weigh 2.5 g of the treated microalgae, put it in a 60 ml autoclave, add 4 ml of ethylene glycol, without catalyst, and seal it. Put the autoclave into the molten salt, control the temperature at 350°C for 60min. After the reaction is completed, quickly cool with water, depressurize and weigh the gas mass, open the reactor, and collect the mixture in the reactor. The reaction mixture was extracted with dichloromethane, separated and filtered to obtain a solid residue and an organic phase, and the dichloromethane was removed by rotary evaporation to obtain bio-oil.

Embodiment 3

[0029] The dried microalgae is pulverized in a pulverizer to obtain microalgae fine particles. Weigh 2.5g of the treated microalgae, put it in a 60ml autoclave, add 4ml of methanol, without catalyst, and seal it. Put the autoclave into the molten salt, control the temperature at 350°C for 60min. After the reaction is completed, quickly cool with water, depressurize and weigh the gas mass, open the reactor, and collect the mixture in the reactor. The reaction mixture was extracted with dichloromethane, separated and filtered to obtain a solid residue and an organic phase, and the dichloromethane was removed by rotary evaporation to obtain bio-oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com