Production process of prestress FRP-rib (fiber reinforce plastic-rib) concrete pipe pile

A technology of concrete pipe piles and manufacturing technology, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as steel bar corrosion and pipe pile damage, and achieve strong bearing capacity, strong corrosion resistance, and novel manufacturing technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] The manufacturing process of prestressed FRP reinforced concrete pipe pile comprises the following steps:

[0029] 1) Concrete production: freshly mixed concrete with a low slump of 4 to 5 cm is produced by a concrete forced mixer, and the concrete strength grade is not lower than C60 or C80;

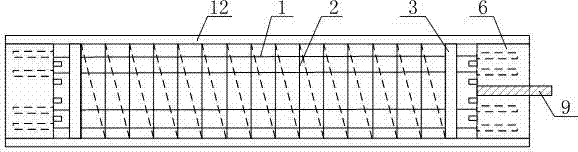

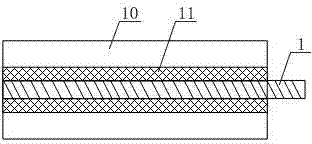

[0030] 2) Fabrication of FRP cage skeleton: make FRP main reinforcement 1 and FRP stirrup 2 according to the required size, and use plastic, nylon rope or non-metal tension belt to bind the FRP main reinforcement and FRP stirrup, and the finished FRP cage The skeleton is similar in appearance to the traditional steel cage;

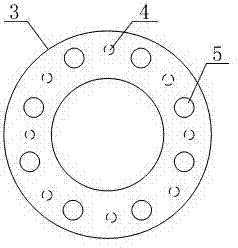

[0031] 3) Production of the end plate: the end plate 3 is circular, and several small holes 4 and several large holes 5 are evenly arranged on the end plate 3, among which the small holes 4 are holes for piercing the FRP main rib 1, and the large h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com