A Construction Method for Improving the Integrity and Lateral Rigidity of Double-row Support Pile in Foundation Pit

A construction method and technology of lateral stiffness, applied in basic structure engineering, excavation, construction, etc., to reduce the bending moment, improve the overall mechanical performance, and improve the lateral stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

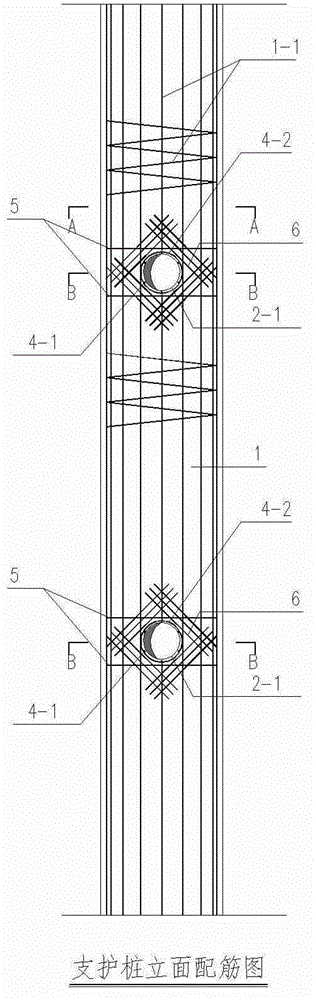

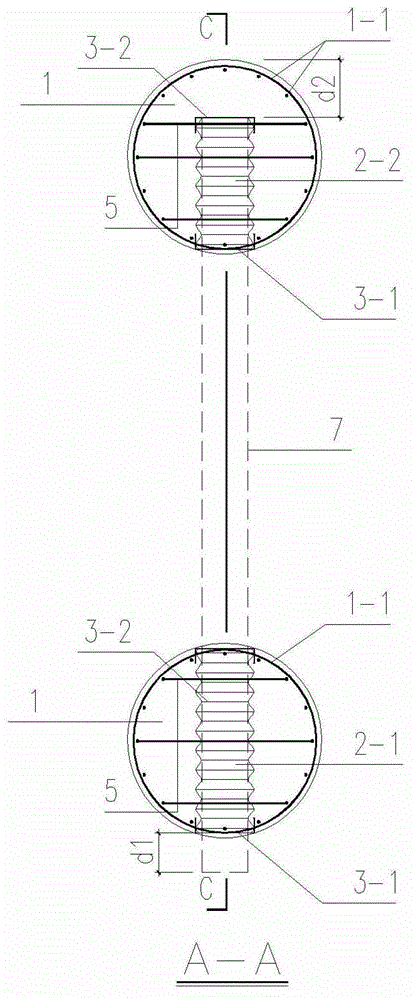

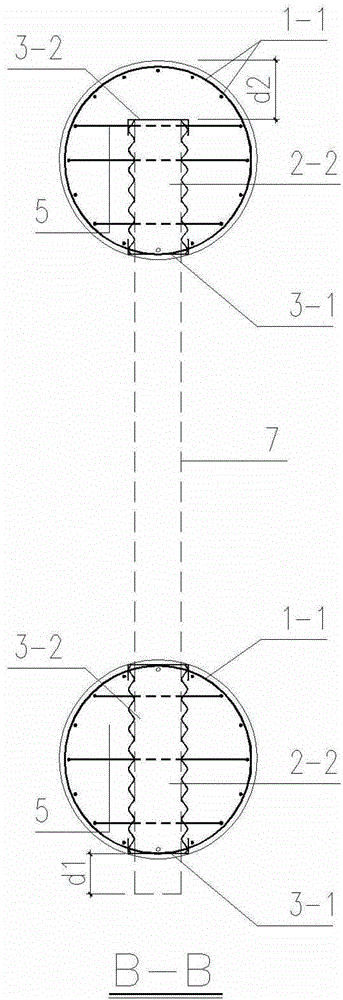

[0042] The excavation depth of the foundation pit is 7m, and a double row of cantilever support piles is set up to support the foundation pit. The diameter of the pile body is 1000mm, and the distance between the front and rear piles is 3000mm. Two longitudinal reinforced concrete web supports are set between the double rows of piles, the center of the first one is 1.5m away from the top of the pile, and the center of the second one is 4m away from the top of the pile. like figure 1 , figure 2 , image 3As shown, a construction method for improving the integrity and lateral stiffness of double-row support piles in foundation pits is implemented as follows:

[0043] Step (1). According to the conventional process, the double-row support piles 1 are drilled, the mud wall is protected, the reinforcement cage 1-1 of the support pile pile body is placed, the holes are cleared, concrete is poured, and maintenance is carried out;

[0044] The first corrugated pipe 2-1, the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com