Face shovel excavation device for optimizing lifting force of movable arm

A technology of working device and lifting force, which is applied in the direction of mechanically driven excavators/dredgers, etc., to achieve the effects of easy motion analysis, easy design and analysis, and uniform force distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

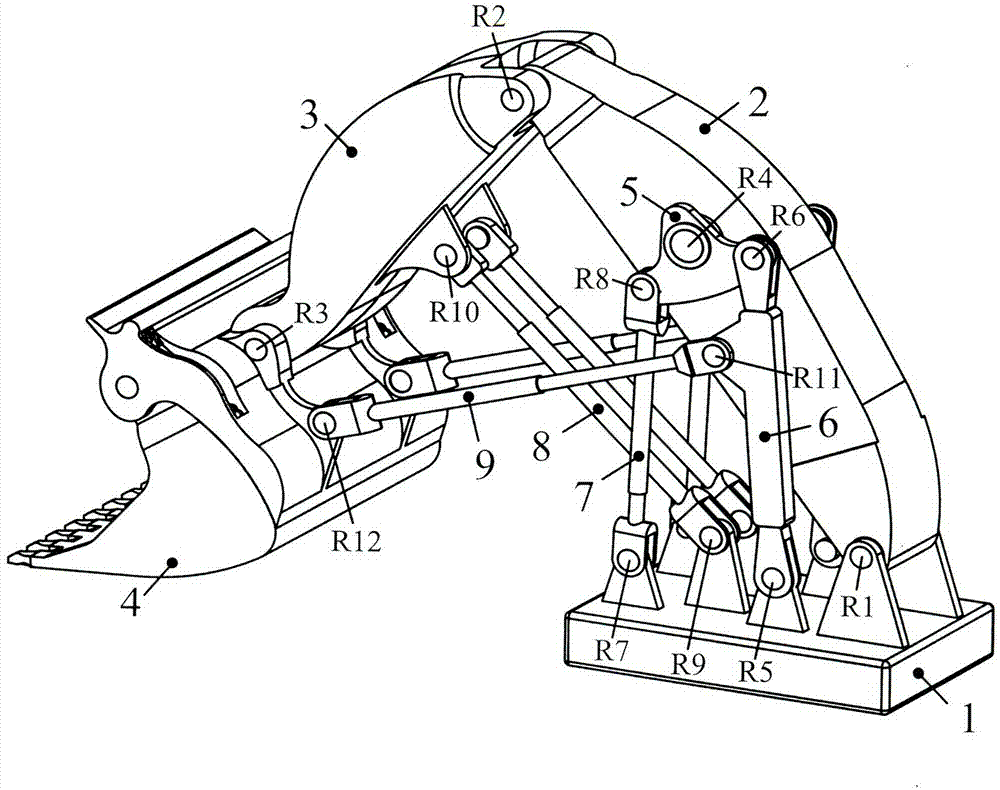

[0027] like figure 1 As shown, the frame 1 of the present invention is hinged to the lower end of the boom 2 through the hinge R1, the upper end of the boom 2 is hinged to one end of the arm 3 through the hinge R2, and the other end of the arm 3 is hinged to the bucket 4 through the hinge R3. A part of the hinge. A pair of boom rockers 5 are symmetrically hinged on both sides of the middle part of the boom 2 through hinges R4, and the pair of boom rockers 5 are respectively hinged with one end of a pair of frame connecting rods 6 through hinges R6. The other end of the frame connecting rod 6 is hinged with the frame through the hinge R5. The cylinder liner ends of a pair of boom hydraulic cylinders 7 are respectively hinged to another part of the boom rocker 5 through the hinge R8, and the piston rod ends of the pair of boom hydraulic cylinders 7 are hinged to the frame through the hinge R7; The cylinder liner ends of a pair of stick hydraulic cylinders 8 are respectively h...

Embodiment 2

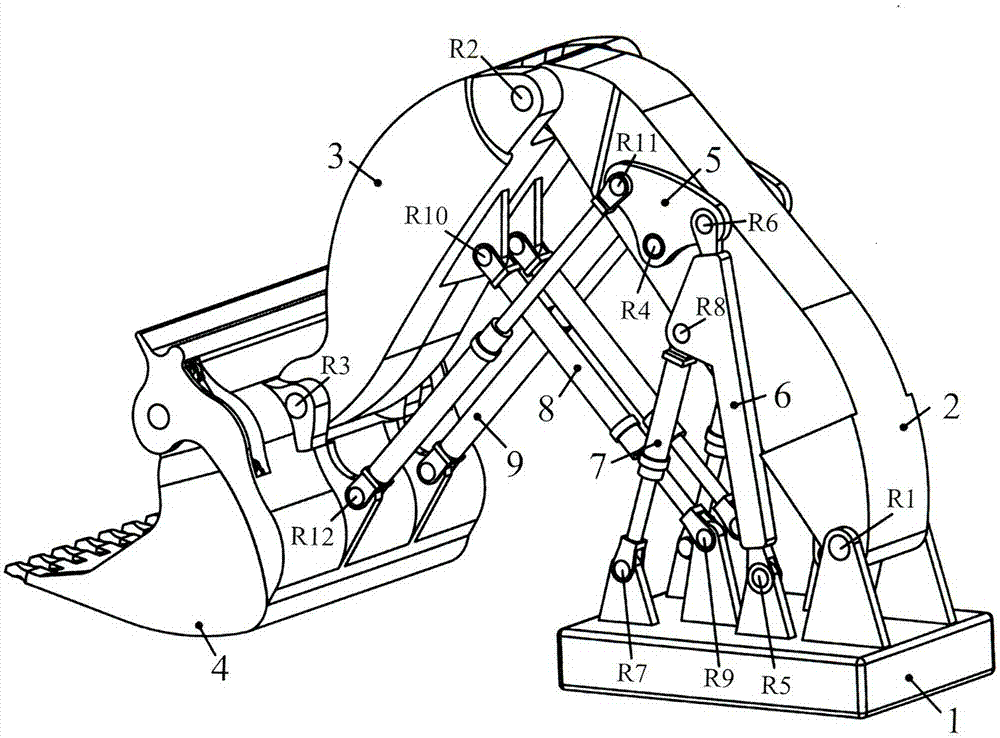

[0029] like figure 2 As shown, one end of the frame 1 of the present invention is hinged to the lower end of the boom 2 through the hinge R1, the upper end of the boom 2 is hinged to one end of the arm 3 through the hinge R2, and the other end of the arm 3 is hinged to the shovel through the hinge R3. A part of bucket 4 is hinged. A pair of boom rockers 5 are symmetrically hinged on both sides of the middle part of the boom 2 through the hinge R4 respectively. The pair of boom rockers 5 are respectively hinged with one end of the pair of frame connecting rods 6 through the hinge R6, and the other ends of the pair of frame connecting rods 6 are respectively hinged with the frame 1 through the hinge R5; the pair of boom hydraulic pressure The ends of the cylinder sleeves of the cylinder 7 are respectively hinged to the middle part of the frame connecting rod 6 through the hinge R8, and the piston rod ends of the pair of boom hydraulic cylinders 7 are respectively hinged to the...

Embodiment 3

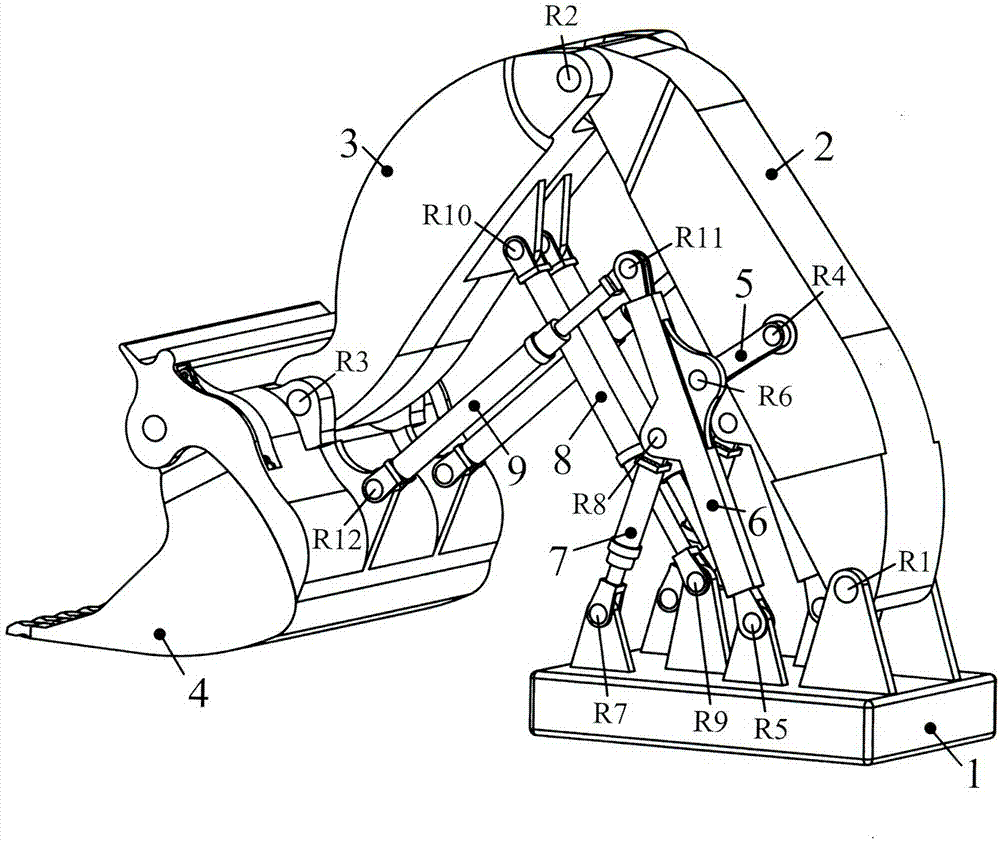

[0031] like image 3 As shown, one end of the frame 1 of the present invention is hinged to the lower end of the boom 2 through the hinge R1, the upper end of the boom 2 is hinged to one end of the arm 3 through the hinge R2, and the other end of the arm 3 is hinged to the shovel through the hinge R3. A part of bucket 4 is hinged. One end of a pair of boom rockers 5 is symmetrically hinged on both sides of the middle part of the boom 2 through a hinge R4, and the other end of the pair of boom rockers 5 is respectively connected to a pair of frame connecting rods 6 through a hinge R6. One part is hinged, and one end of the pair of frame connecting rods 6 is respectively hinged with the frame 1 through the hinge R5; Hinged, the piston rod ends of the pair of boom hydraulic cylinders 7 are hinged with the frame 1 through the hinge R7 respectively; The piston rod ends of the pair of stick hydraulic cylinders 8 are respectively hinged with the frame 1 through the hinge R9; the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com