Turbojet engine

A turbojet and engine technology, which is applied in the direction of machines/engines, jet propulsion devices, etc., can solve the problems of turbojet engine damage, insufficient air intake in the combustion chamber, and reverse flow of airflow, so as to reduce the probability of surge and reduce airflow Backflow phenomenon, the effect of increasing the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand the technical ideas claimed in the present invention more clearly.

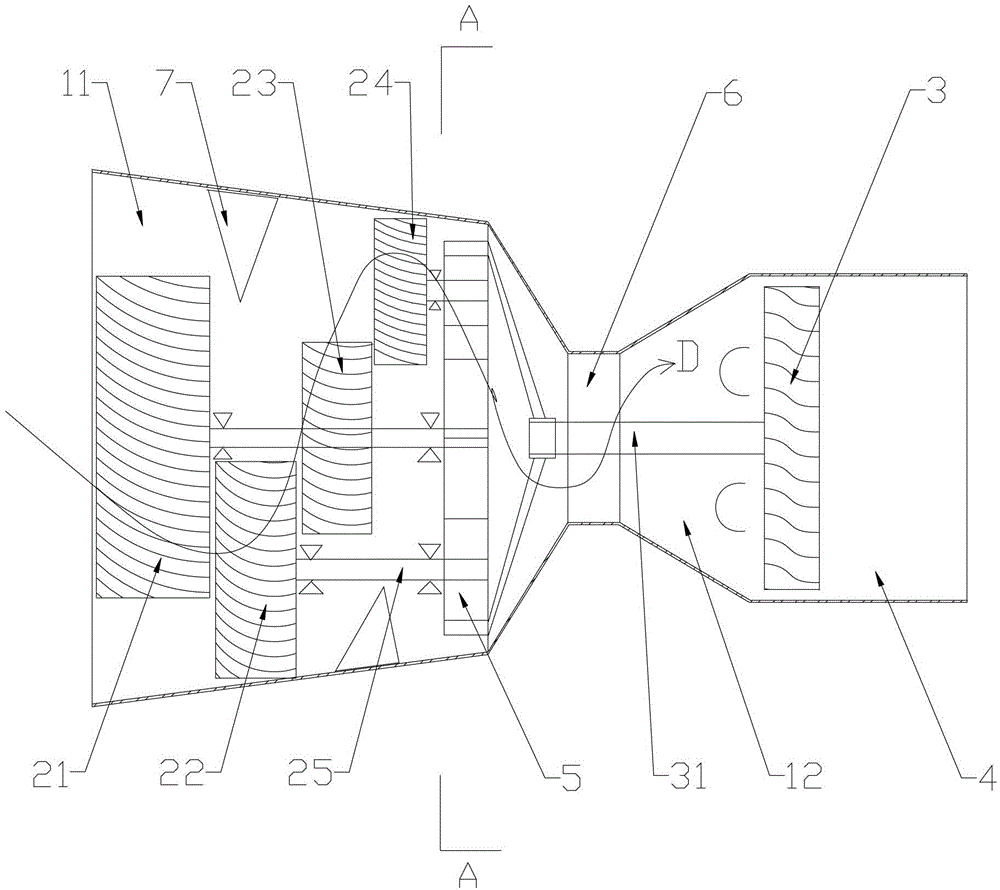

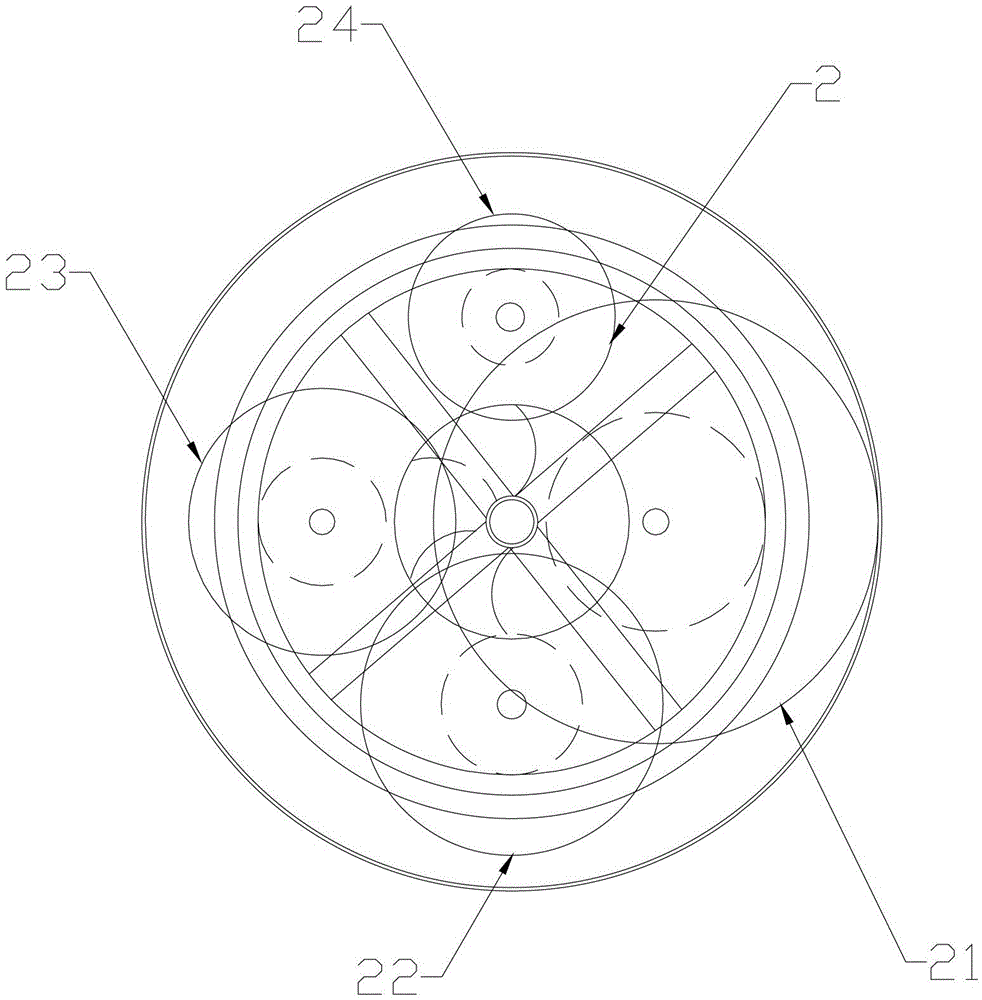

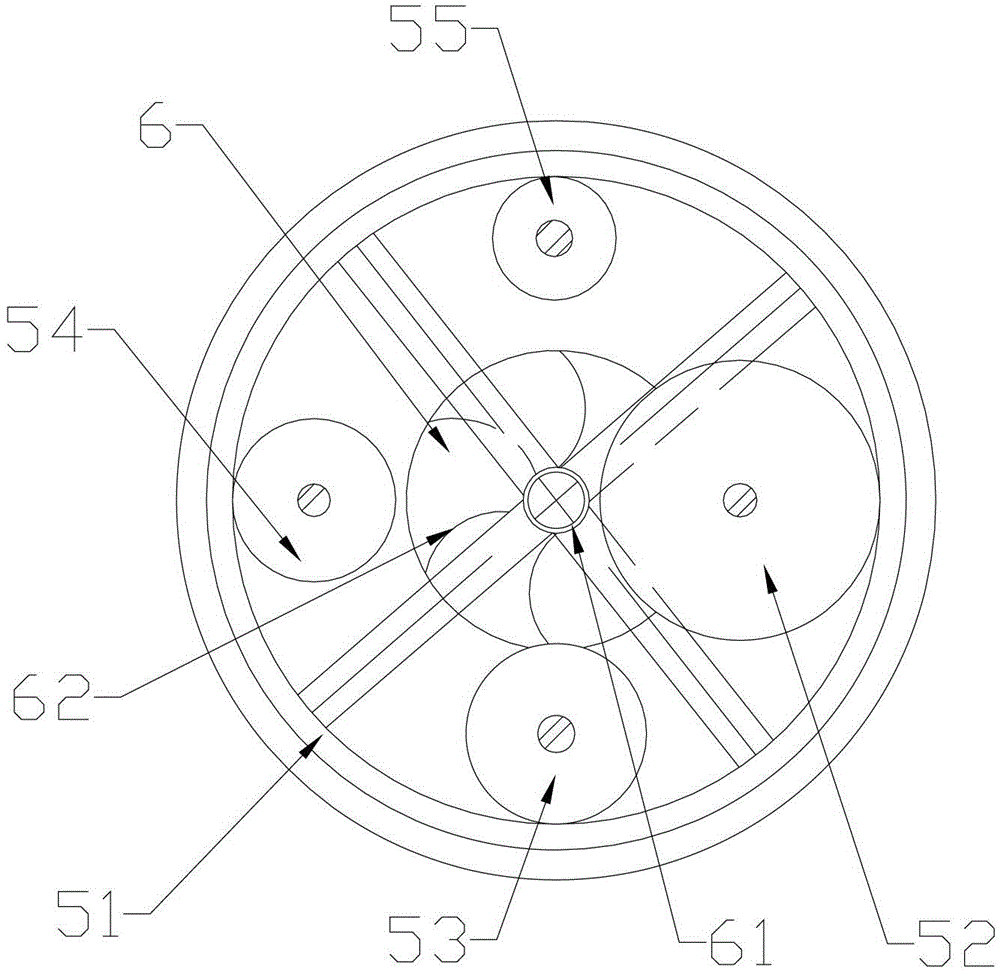

[0022] Such as figure 1 , 2 , shown in 3, is a kind of turbojet engine of the present invention, comprises casing, is arranged on the intake passage 11 in the casing, is arranged on the combustion chamber 12 that is arranged in the casing and is positioned at the intake passage 11 rear, is installed in the air intake In the channel 11, there is an air compressor assembly 2 for inhaling air and pushing the air to rotate toward the direction of the combustion chamber 12, a rotatable turbine 3 behind the combustion chamber 12, and a tailpipe 4 for ejecting high-speed gas. The compressed air assembly 2 includes four compressed air devices 21-24; the compressed air devices 21-24 may be compressed air fans or the like. The distances between the four c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com