Sub-wavelength grating true color element and color generating product containing same

A subwavelength grating and component technology, applied in the field of color products, can solve the problems of only red and green changes, insufficient color types of optical anti-counterfeiting components, single color types and changing effects, etc., and achieve the effect of improving saturation and brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

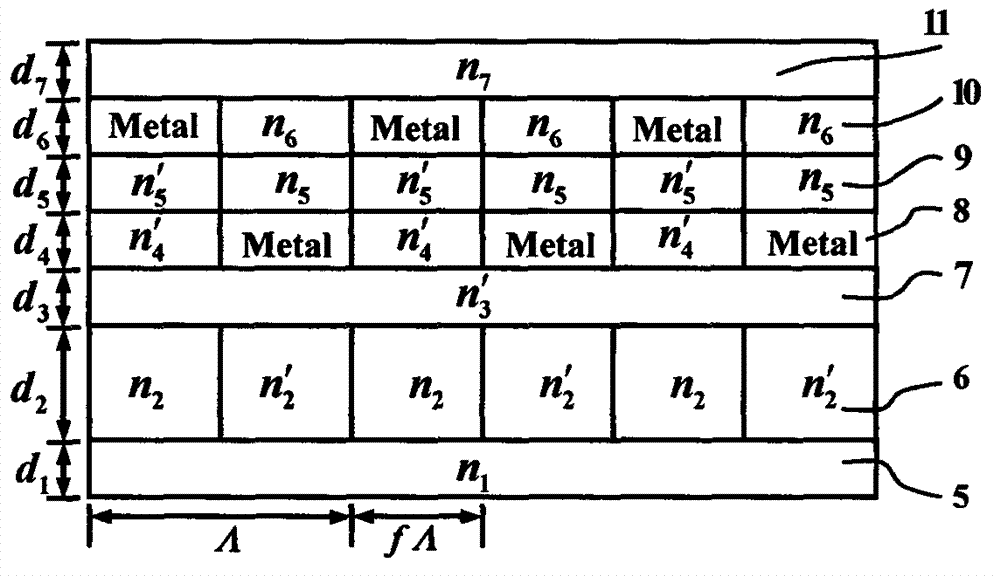

[0033] see figure 2 , the depths of structural layers 5-11 are 0.5 μm, 0.08 μm, 0.055 μm, 0.02 μm, 0.06 μm, 0.02 μm and 0.6 μm in sequence; the period Λ is 0.33 μm, f is 0.5; the material “Metal” is Ag; the medium n 1 and n 2 PMMA (1.49); medium n 5 , n 6 and n 7 is BOPP(1.5); medium n' 2 , n' 3 , n' 4 and n' 5 TiO 2 (2.3); the incident light wavelength is 0.38-0.8 μm, and the incident angle θ is 5°.

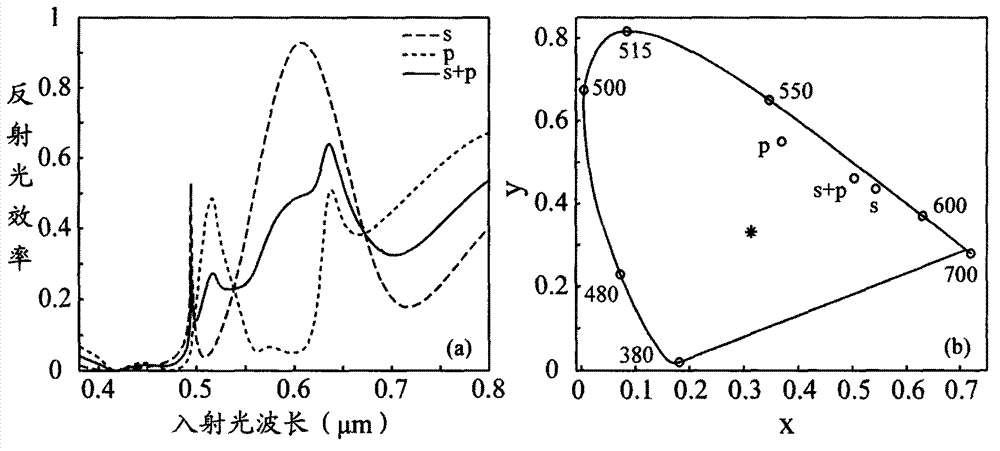

[0034] image 3 It is the spectrum and chromaticity diagram of s and p polarized light and unpolarized light of the subwavelength grating true color element. see image 3 , the spectrum of s-polarized light has a significant peak near 0.608 μm (efficiency is close to 95%), and the corresponding color position on the CIE x-y chromaticity diagram is (0.54, 0.43), that is, orange-red (RGB value is 255, 74 and 0); the spectrum of p-polarized light has sharp peaks near 0.512 μm and 0.635 μm (efficiency is close to 50%), and the corresponding color position on the CIE x-y...

Embodiment 2

[0036] see figure 2 , the depths of structural layers 5-11 are 0.5 μm, 0.06 μm, 0.09 μm, 0.015 μm, 0.045 μm, 0.015 μm and 0.6 μm in sequence; the period Λ is 0.25 μm, f is 0.5; the material “Metal” is Ag; the medium n 1 and n 2 for SiO 2 (1.46); medium n 5 , n 6 and n 7 for MgF 2 (1.38); medium n' 2 , n' 3 , n' 4 and n' 5 ZrO 2 (2.0); the incident light wavelength is 0.38-0.8 μm, and the incident angle θ is 5°.

[0037] Figure 4 It is the spectrum and chromaticity diagram of s and p polarized light and unpolarized light of the subwavelength grating true color element. see Figure 4 , the spectrum of s-polarized light has a sharp peak near 0.428 μm (efficiency is close to 80%), and the corresponding color position on the CIE x-y chromaticity diagram is (0.25, 0.16), that is, blue-violet (RGB value is 116, 39 and 255); the spectrum of p-polarized light has a higher efficiency value between 0.6-0.8 μm, and the corresponding color position on the CIE x-y chromatici...

Embodiment 3

[0039] see figure 2 , the depths of structural layers 5-11 are 0.8 μm, 0.12 μm, 0.16 μm, 0.025 μm, 0.095 μm, 0.025 μm and 0.8 μm in sequence; the period Λ is 0.31 μm, f is 0.55; the material “Metal” is Ag; the medium n 1 and n 2 For PVC (1.54); medium n 5 , n 6 and n 7 for SiO 2 (1.46); medium n' 2 , n' 3 , n' 4 and n' 5 for Zr 2 o 5 (2.0); the incident light wavelength is 0.38-0.8 μm, and the incident angle θ is 0°.

[0040] Figure 5 It is the spectrum and chromaticity diagram of s and p polarized light and unpolarized light of the subwavelength grating true color element. see Figure 5 , the spectrum of s-polarized light has a significant peak near 0.508 μm (efficiency is close to 93%), and the corresponding color position on the CIE x-y chromaticity diagram is (0.24, 0.54), that is, light green (RGB value is 0, 255 and 45); although the spectrum of p-polarized light has peaks near 0.46 μm and 0.56 μm, the efficiency is low (not higher than 45%) and the effic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Grating period | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com