Nanofluid magnetic wheel power generator and manufacture method thereof

A nano-fluid and manufacturing method technology, applied in the field of nano-fluid magnet wheel generator and its manufacturing, can solve the problems of high cost, increased vehicle weight, negative impact on safe driving of vehicles, etc., and achieves simple manufacturing process, high power generation efficiency, weight light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

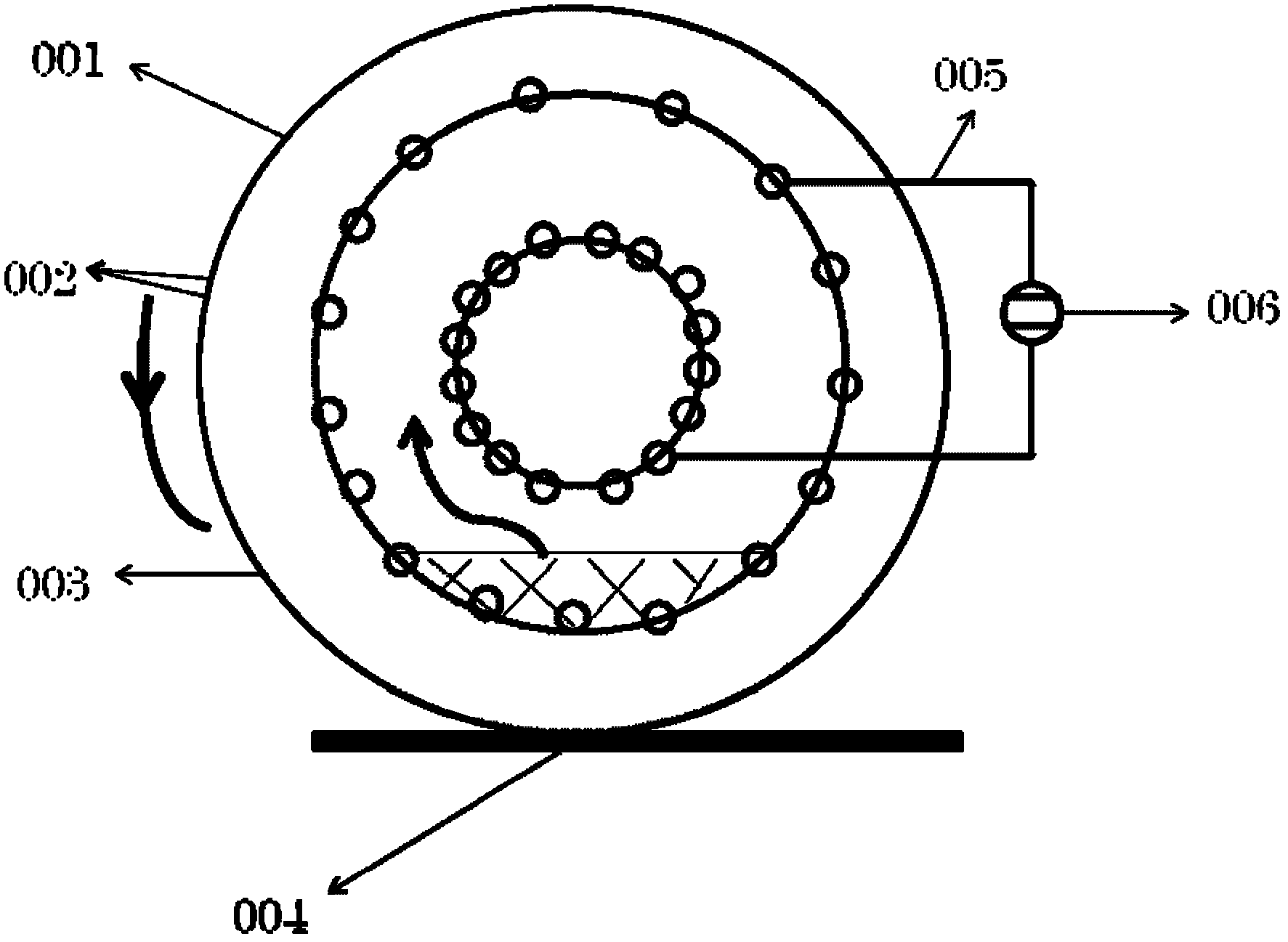

[0031] The invention provides a nanofluid magnet wheel generator and a manufacturing method thereof.

[0032] The nanofluid magnet wheel generator includes a wheel tire and a conductive brush fixed on one side of the wheel tire, wherein: the rotor coil is fixed inside the wheel tire; fluid magnets are injected into the wheel tire; the two output terminals of the rotor coil are connected to the The conductive brushes are connected.

[0033] The manufacturing method of the nano wheel generator comprises the following steps: 1) making the rotor coil; 2) fixing the rotor coil in the tire, connecting the two output terminals of the rotor coil with the conductive brush; 3) installing the rotor coil on the tire Inject fluid magnets inside.

[0034] The invention will be described in detail below by means of preferred embodiments with reference to the accompanying drawings.

[0035] refer to figure 1 . First, a rotor coil 002 is installed in a wheel tire 001 as a closed-tube circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com