Bunchy yarn towel preparation method

A technology of slub yarn and towel, which is applied in fabrics, textiles, textiles and papermaking, etc., can solve problems such as poor hand feeling, difficulty in marketing, failure to satisfy high-end customers and consumer groups, etc., and achieve the goal of improving product quality and good artistic effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

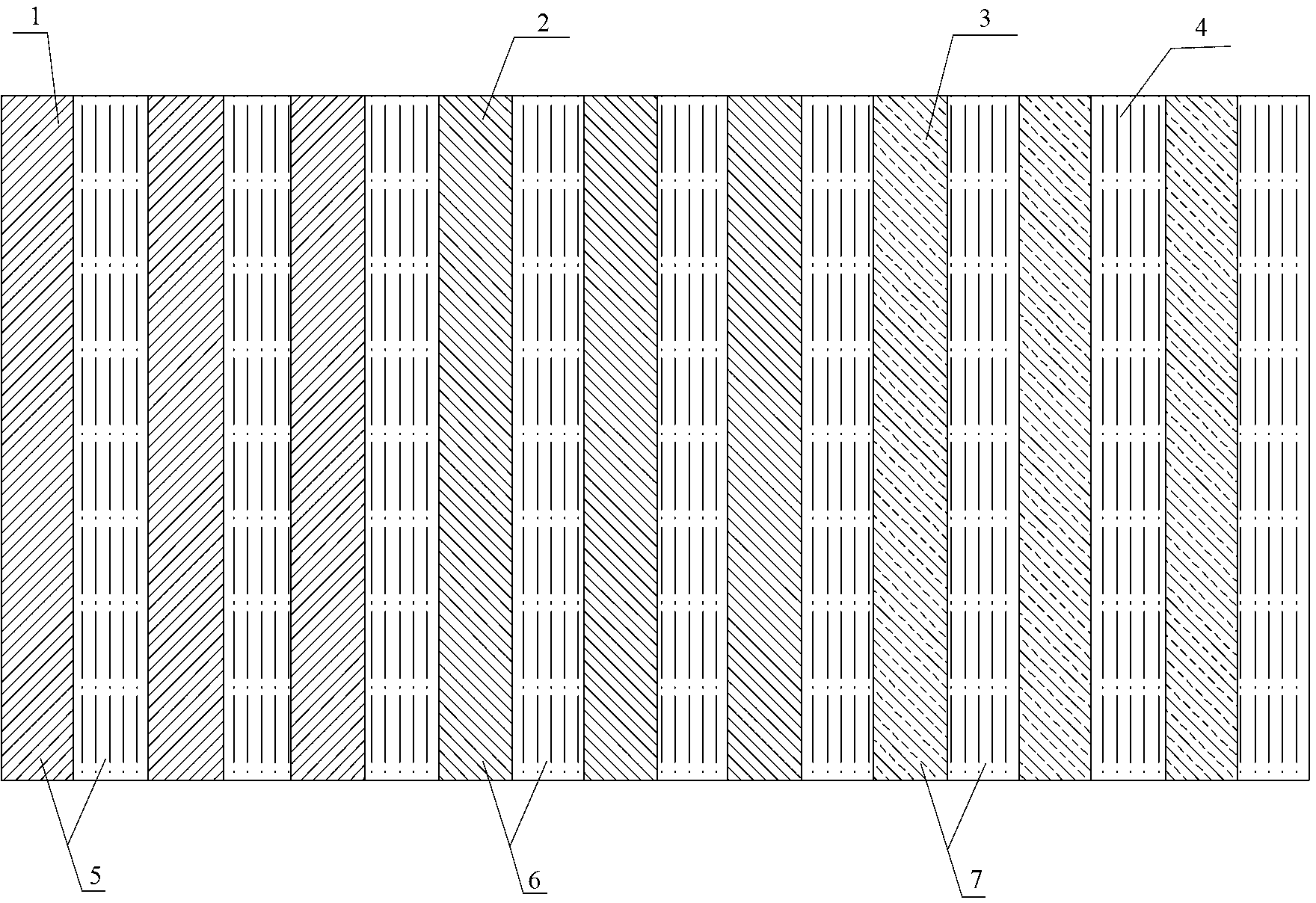

Image

Examples

Embodiment 1

[0025] A kind of preparation method of slub yarn towel, its specific steps are:

[0026] (1) Pretreatment The slub yarn is pretreated, and its specific parameters are: add caustic soda (mass fraction 32%): 8g / l, high-concentration refining enzyme JN-98: 1.5g / l, hydrogen peroxide stabilizer in sequence : 2g / l, chelating agent SNS: 2g / l, hydrogen peroxide: 7g / l, heat up to 110 degrees, keep warm for 90min; the slub yarn used is 8.5S thick yarn, 7.0cm long, 24.5S detailed yarn, twist 75 Twist / 10cm, length 24.5cm;

[0027] (2) Dyeing Wash the pre-treated slub yarn and then dye it. The dyeing temperature is 60°C and the pH value is 10.8;

[0028] (3) Color fixation Wash the dyed slub yarn with water and fix the color at 40°C, the pH value of the color fixation is 6;

[0029] (4) Soaping Wash the fixed slub yarn with water and then soap it at 95°C, and the pH value of the soaping is 7;

[0030] (5) Sizing Wash and dry the soaped slub yarn, then lightly starch at 95°C, wash inside...

Embodiment 2

[0036] A kind of preparation method of slub yarn towel, its specific steps are:

[0037](1) Pretreatment The slub yarn is pretreated, and its specific parameters are: add caustic soda (mass fraction 32%): 8g / l, high-concentration refining enzyme JN-98: 1.5g / l, hydrogen peroxide stabilizer in sequence : 2g / l, chelating agent SNS: 2g / l, hydrogen peroxide: 7g / l, heat up to 110 degrees, keep warm for 90min; the slub yarn used is 8.5S thick yarn, 7.0cm long, 24.5S detailed yarn, twist 75 Twist / 10cm, length 24.5cm;

[0038] (2) Dyeing Wash the pre-treated slub yarn and then dye it. The dyeing temperature is 60°C and the pH value is 10.9;

[0039] (3) Color fixation Wash the dyed slub yarn and fix the color at 40°C, the pH value of the color fixation is 5.5;

[0040] (4) Soaping Wash the fixed slub yarn with water and then soap it at 95°C, and the pH value of the soaping is 7;

[0041] (5) Sizing Wash and dry the soaped slub yarn, then lightly starch at 95°C, wash inside for 13 mi...

Embodiment 3

[0047] A kind of preparation method of slub yarn towel, its specific steps are:

[0048] (1) Pretreatment The slub yarn is pretreated, and its specific parameters are: add caustic soda (mass fraction 32%): 8g / l, high-concentration refining enzyme JN-98: 1.5g / l, hydrogen peroxide stabilizer in sequence : 2g / l, chelating agent SNS: 2g / l, hydrogen peroxide: 7g / l, heat up to 110 degrees, keep warm for 90min; the slub yarn used is 8.5S thick yarn, 7.0cm long, 24.5S detailed yarn, twist 75 Twist / 10cm, length 24.5cm;

[0049] (2) Dyeing Wash the pre-treated slub yarn and then dye it. The dyeing temperature is 60°C and the pH value is 11;

[0050] (3) Color fixation Wash the dyed slub yarn with water and fix the color at 40°C, and the pH value of the color fixation is 5;

[0051] (4) Soaping Wash the fixed slub yarn with water and then soap it at 95°C, and the pH value of the soaping is 7;

[0052] (5) Sizing Wash and dry the soaped slub yarn, then lightly starch at 95°C, wash insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com