Breathing machine, anaesthesia machine and flow proportional valve

A flow proportional valve and fluid channel technology, which is applied in the fields of anesthesia machines, flow proportional valves, and ventilators, can solve the problems that flow proportional valves cannot meet the requirements of large flow control, and achieve good therapeutic effects, fast response speed, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in a variety of different ways defined and covered by the claims.

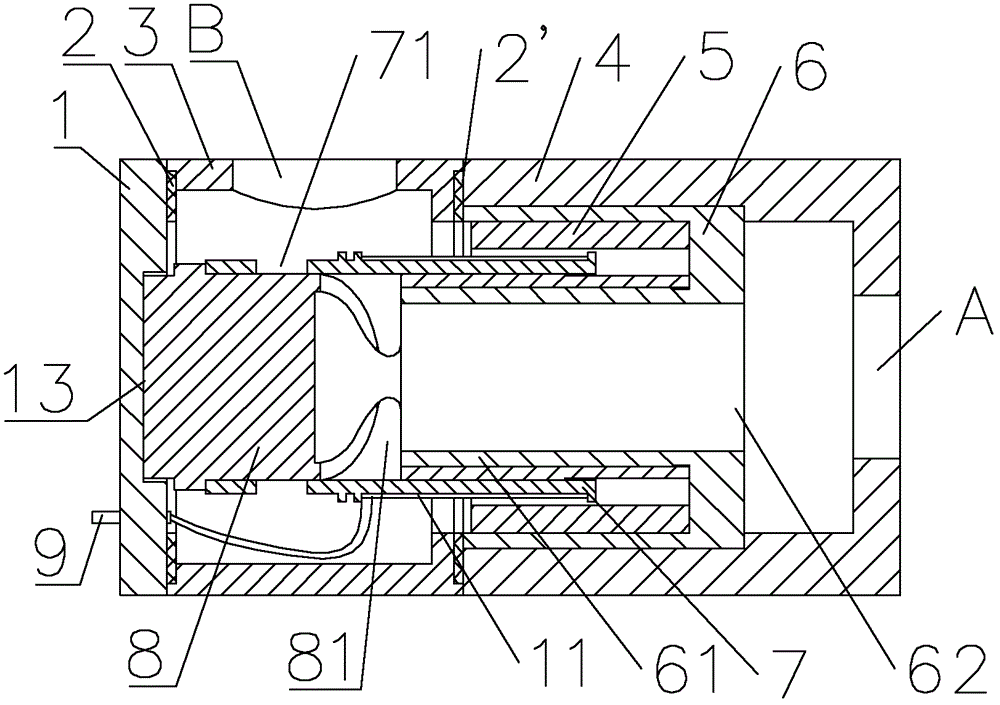

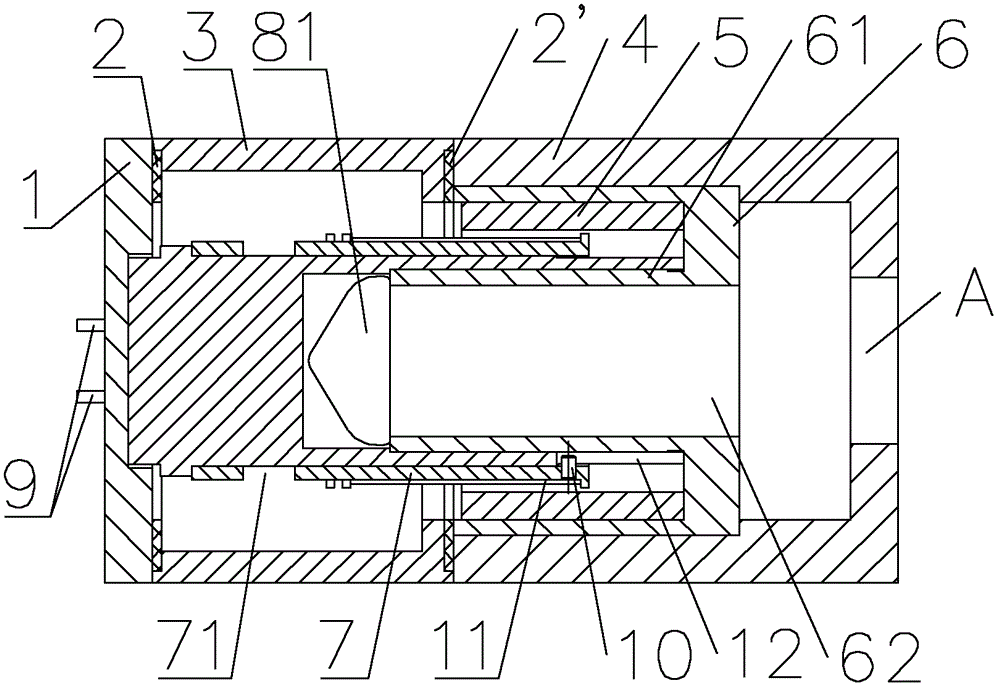

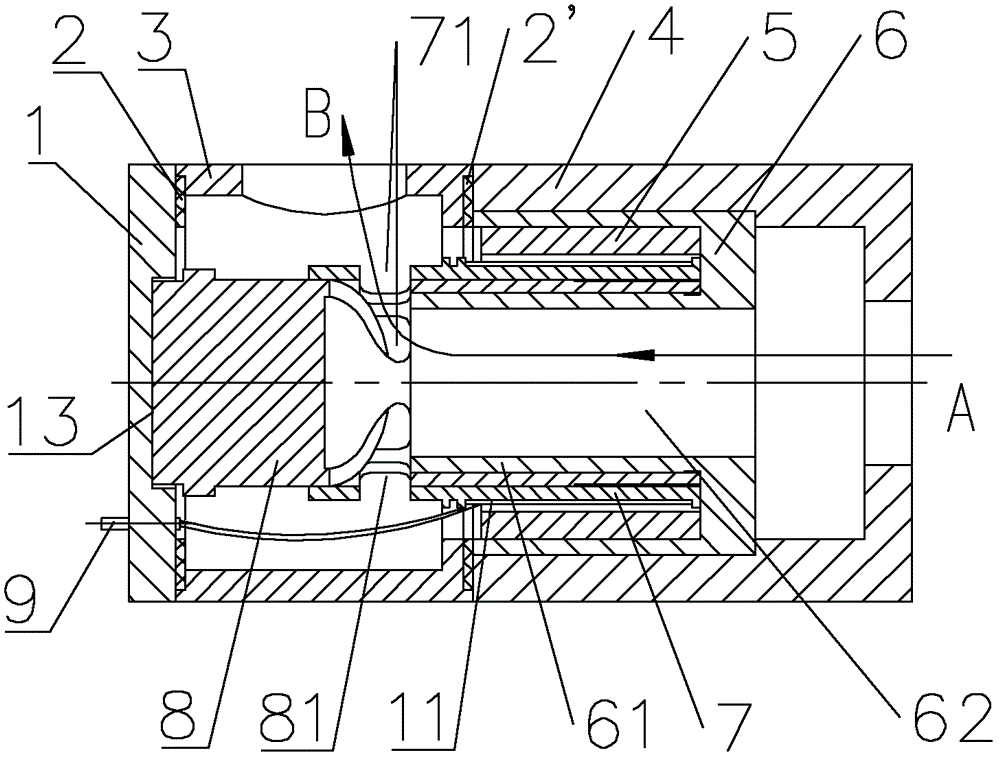

[0029] As the first aspect of the present invention, the present invention provides a flow proportional valve. Such as Figure 1-4 As shown, the flow proportional valve in the present invention includes: a housing with an inlet A and an outlet B; the flow proportional valve also includes a yoke 6, a central shaft sleeve 8, a sliding sleeve 7 and a magnet provided in the housing 5; The yoke 6 includes a guide portion 61, the guide portion 61 has a fluid passage 62, the first end of the fluid passage 62 is in communication with the inlet A; the central sleeve 8 includes an axial hole through which the central sleeve 8 is fixedly ground It is sleeved on the guide portion 61, the central shaft sleeve 8 is provided with a first opening 81 communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com