Numerical control drilling tool with multi-spindle and bi-directional processing function

A two-way processing and machine tool technology, applied in the field of machine tools, can solve the problem that the indexing hole cannot be processed quickly, and achieve the effect of high processing efficiency and good surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

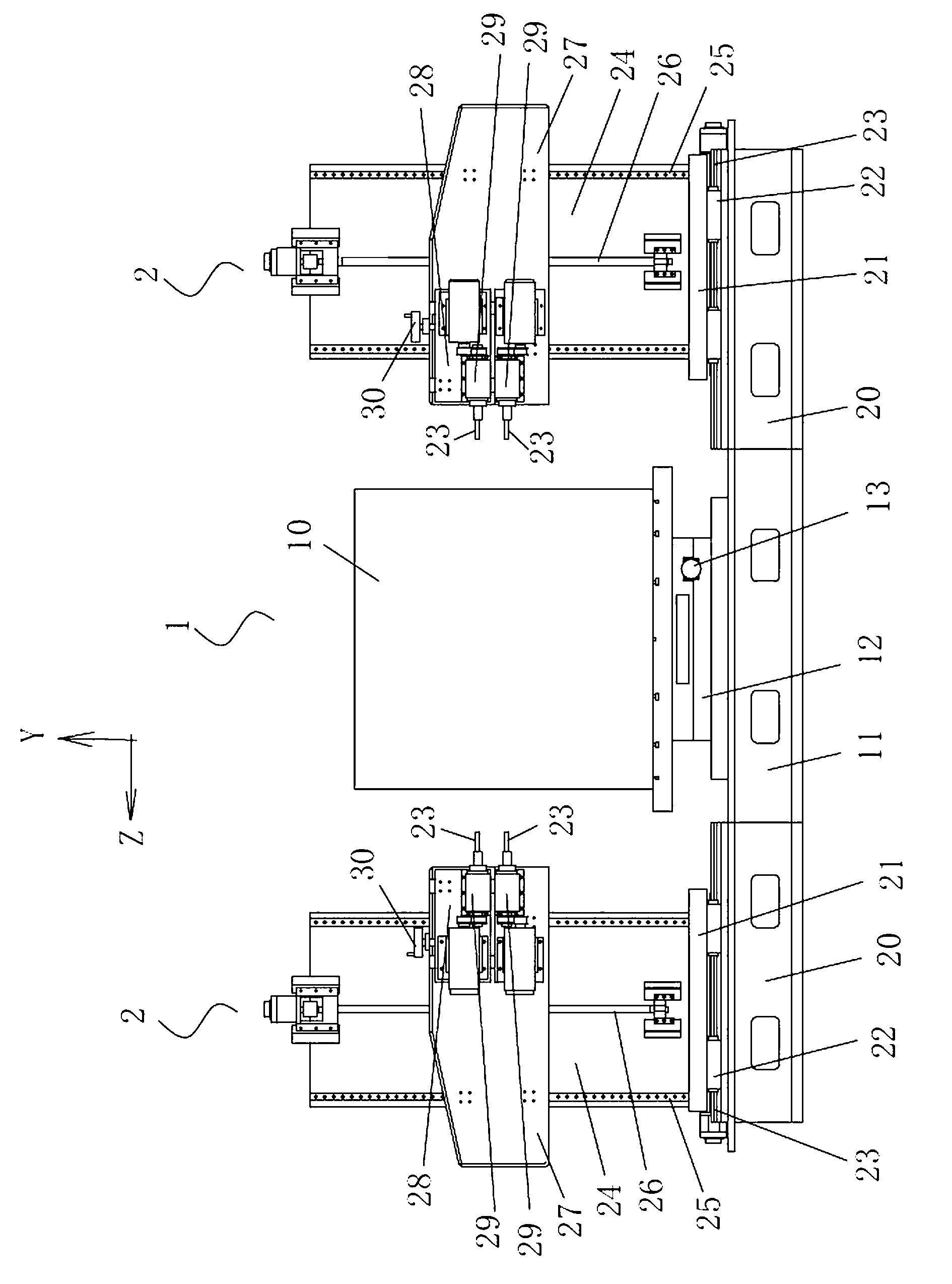

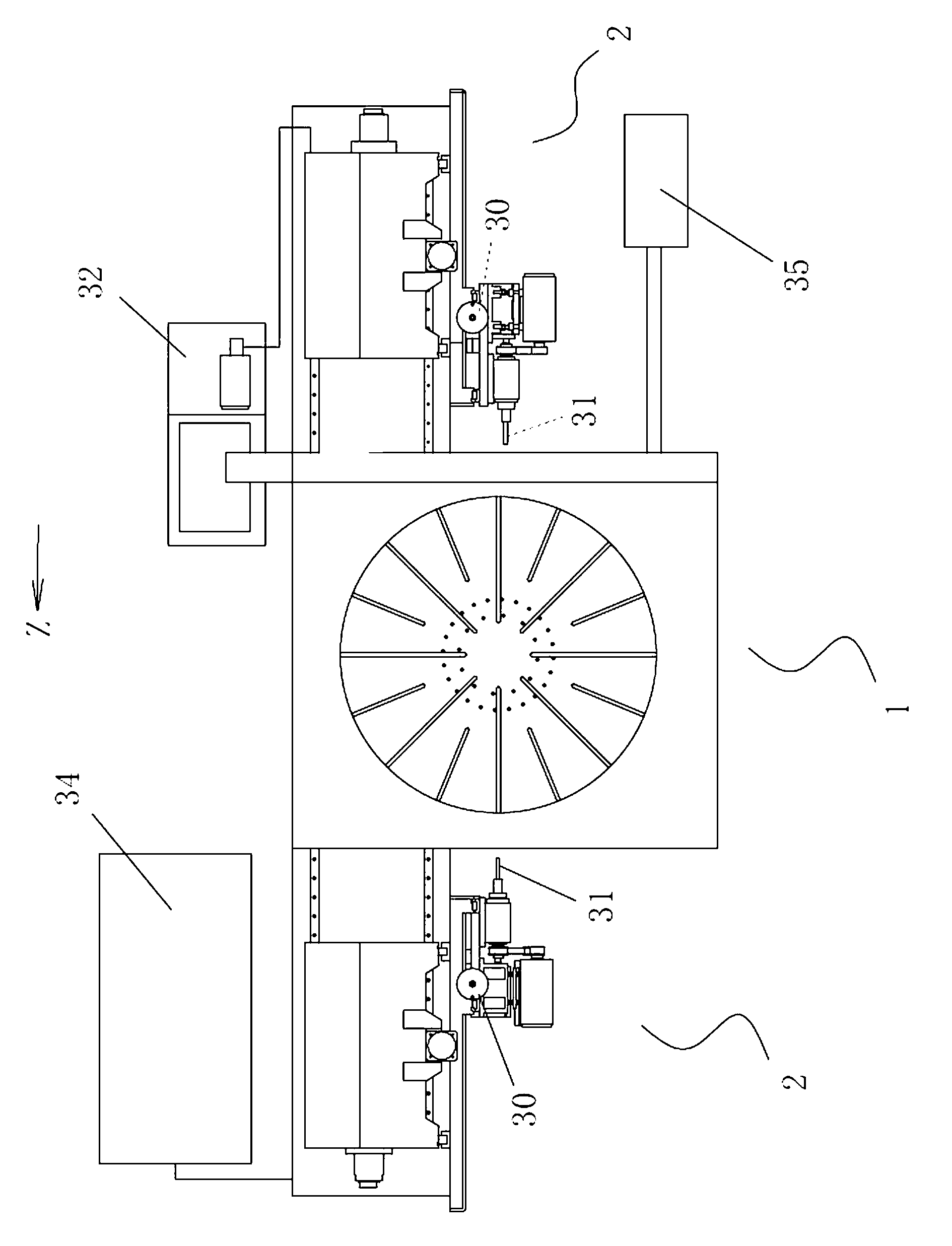

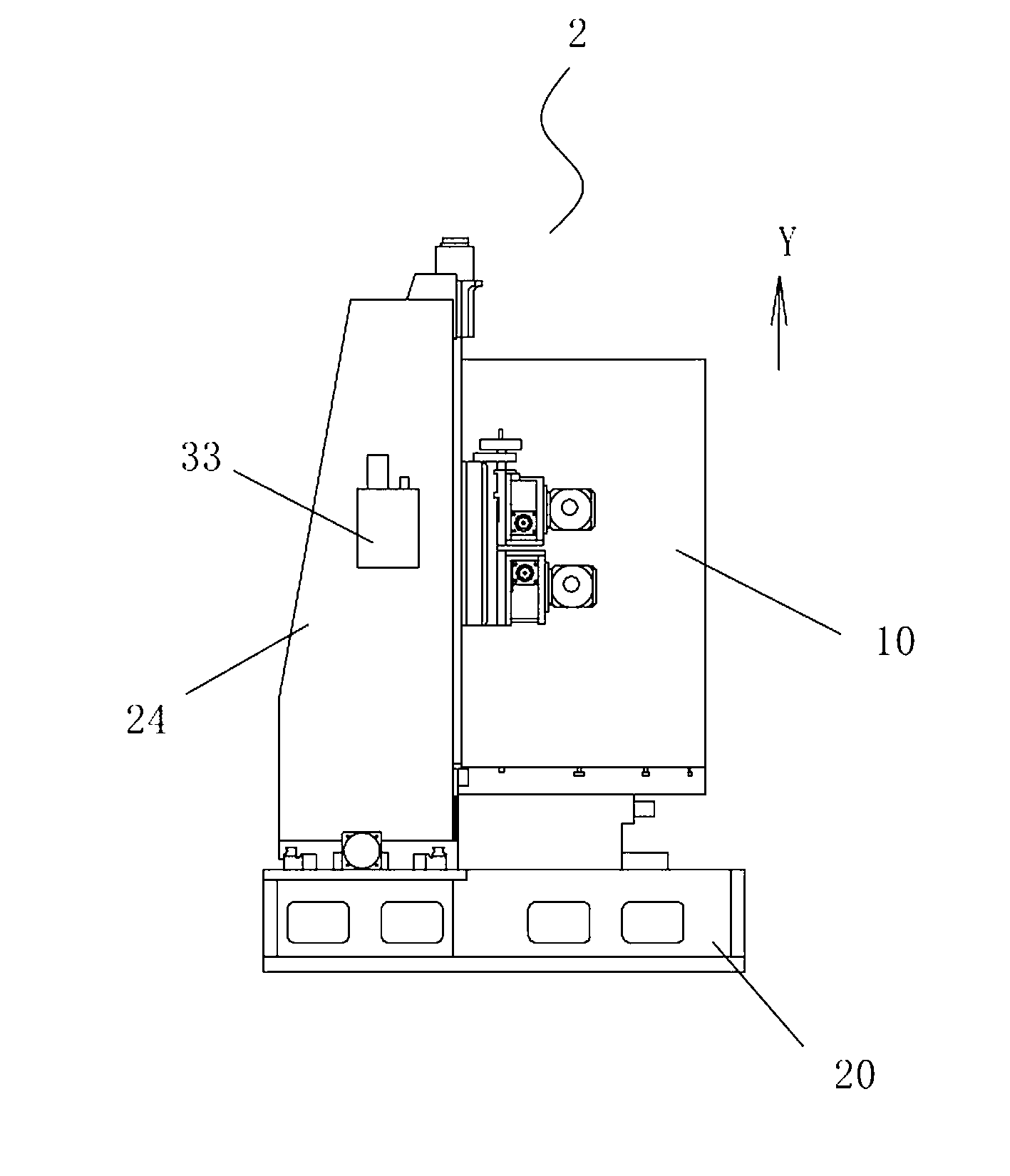

[0023] like figure 1 , figure 2 and image 3 As shown, a multi-axis bidirectional machining CNC drilling machine tool is arranged horizontally. It includes a workpiece clamping unit 1 and a feed unit 2, and a feed unit 2 is arranged on the left and right of the workpiece clamping unit 1; the workpiece clamping unit 1 is a numerically controlled rotary table capable of clamping a workpiece 10 to be processed. The feed unit 2 is a system that supports and can control the feed of the main shaft parts in the horizontal and up and down directions to perform deep hole processing on the workpiece 10 to be processed. Each of the feed units 2 includes two sets of main shaft parts for installing drilling tools , the two sets of main shaft parts are arranged in parallel up and down in position, wherein one set of main shaft parts moves up and do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com