Method of Rough Machining the Sealing Surface of Honeycomb Seals Using CNC Milling Machine

A honeycomb sealing, CNC milling machine technology, applied in milling machine equipment, milling machine equipment details, metal processing equipment and other directions, can solve the problems of low processing efficiency, large electrode loss, etc., to achieve easier removal, small sealing surface burrs, and reduce flanging. effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

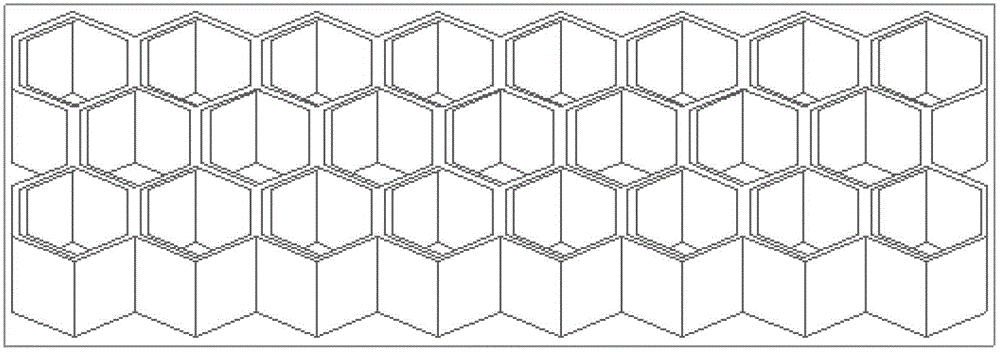

[0011] The method for rough machining the sealing surface of the honeycomb seal with a numerically controlled milling machine according to the present invention will be further described below through examples and in conjunction with the accompanying drawings.

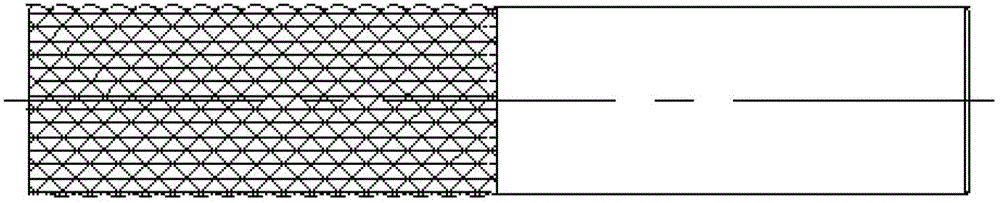

[0012] In this embodiment, the sealing surface of the Φ600 honeycomb seal is roughly processed, and the metal sheet constituting the honeycomb seal is MSRR6624 / ERH corrosion-resistant steel foil. The milling machine used is a conventional CNC milling machine (model: VMC1250), and the milling cutter is figure 1 The shown corn sawtooth overall alloy milling cutter CBDB1000AXBS K600 [US KENNAMETAL company (Kenna company) production].

[0013] Place the processed honeycomb seal on the CNC milling machine and fix it, choose the down-milling method, control the spindle speed of the CNC milling machine at 2300 r / min, control the feed rate of the milling cutter at 0.15mm, and control the linear speed of the milling cutter at 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com