Composite flame retarding reinforced plate

A composite flame-retardant and reinforced board technology, which is applied to wood processing appliances, household components, flat products, etc., can solve the problems of high density of medium density fiberboard, unsatisfactory flame-retardant performance, and limited use range, etc., so as to improve the impact strength, Simple structure and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

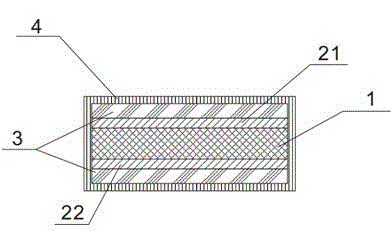

[0012] As an embodiment of the present invention, see figure 1 , the present invention includes a plate body, the plate body includes a base plate 1, the upper surface and the lower surface of the base plate 1 are hot-compressed and composited with a panel 21 and a back plate 22 respectively, and the side of the face plate 21 and the back plate 22 away from the base plate 1 is fixedly connected with a reinforcing plate 3 , the outer wall of the plate body is coated with a flame retardant layer 4 . Both the face plate 21 and the back plate 22 are flame retardant medium density fiberboards.

[0013] The present invention has the advantages of simple structure, convenient processing, wide application range, and is suitable for market promotion. The face plate 21 and the back plate 22 are fixedly connected with a reinforcement plate 3 on the side away from the base plate 1, which can improve the impact strength. The outer wall of the plate body is coated with a flame retardant La...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com