Aluminum alloy plate, and joint body and automobile member using same aluminum alloy plate

A technology of aluminum alloy plates and aluminum alloy substrates, which is applied in the field of automotive components and joints, can solve the problems that the stability of surface characteristics cannot be guaranteed, and achieve excellent moisture stability, difficult to reduce adhesion strength, and adhesion durability excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0172] Next, the aluminum alloy plate of the present invention will be specifically described by comparing Examples satisfying the requirements of the present invention and Comparative Examples not satisfying the requirements of the present invention.

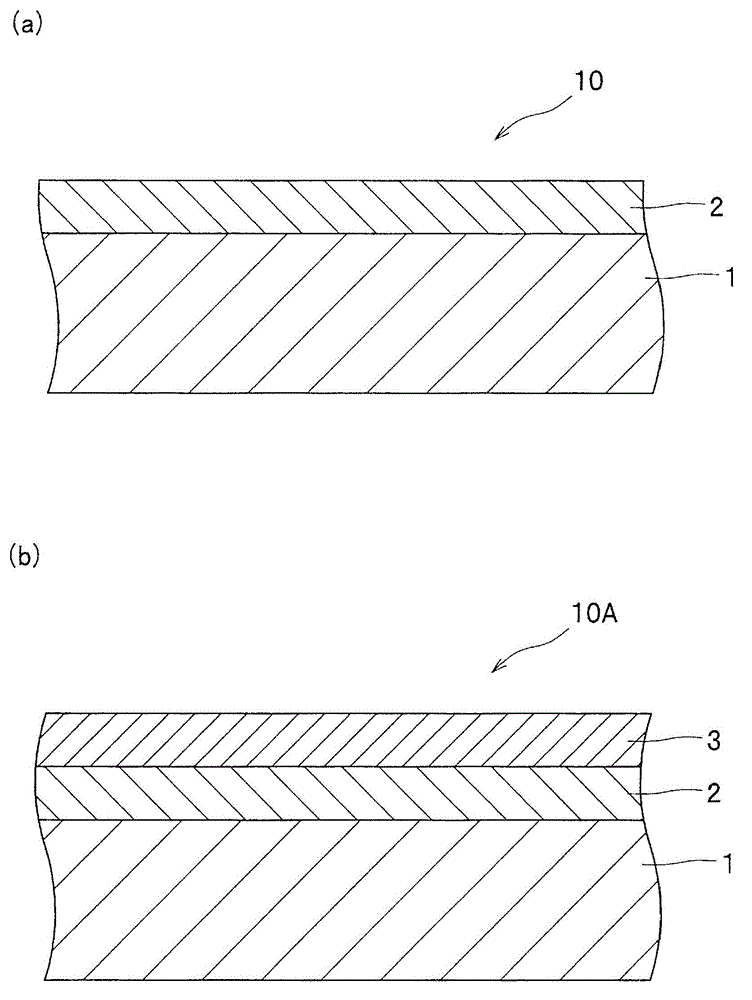

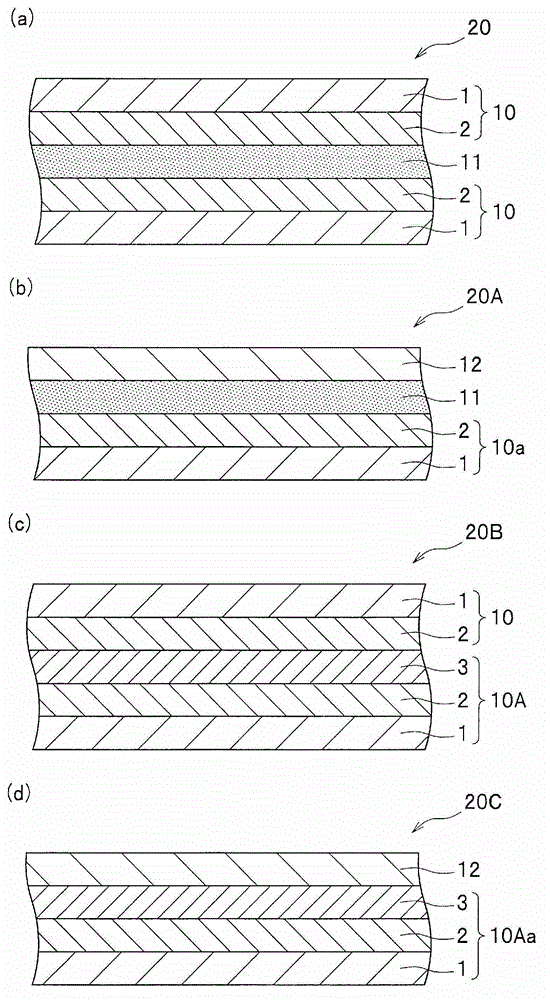

[0173] Using the 6000-series aluminum alloy of the 6022 standard (Mg: 0.55% by mass, Si: 0.95% by mass) prescribed by JIS, an aluminum alloy cold-rolled sheet (thickness 1 mm) was produced by the above-mentioned production method. The 0.2% proof stress of this cold-rolled sheet was 230 MPa. Then, this cold-rolled sheet was used as a sheet for evaluation of adhesion durability, and was cut into a length of 100 mm×width of 25 mm to form a substrate. In addition, as a plate for evaluation of moisture stability, it was cut into a length of 70 mm×width of 150 mm to form a substrate. Alkaline degreasing is carried out to above-mentioned substrate, substrate is carried out heat treatment until solid reaching temperature 550 ℃, after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com