Planet gear connecting rod combined paper feeding device

A combination technology of planetary gears and connecting rods, which is applied in the direction of rotary printing machines, printing machines, printing machines, etc., can solve the problems of high processing and manufacturing precision, complex cam curve design, large moment of inertia of the device, etc., and achieve low meshing noise and effective Conducive to maintenance and maintenance, improve the effect of printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A preferred embodiment of the present invention is described as follows in conjunction with accompanying drawing:

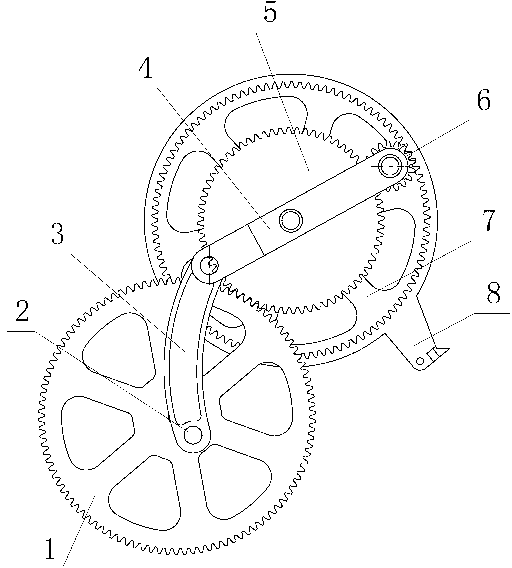

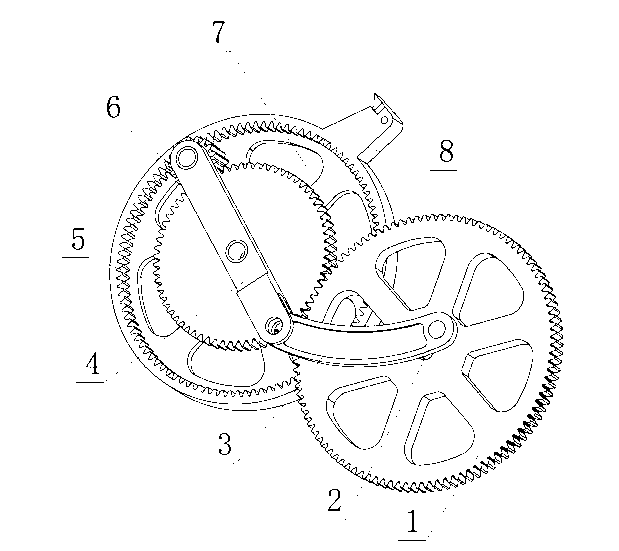

[0017] see figure 1 with figure 2 , the planetary gear connecting rod combination paper delivery device, it includes

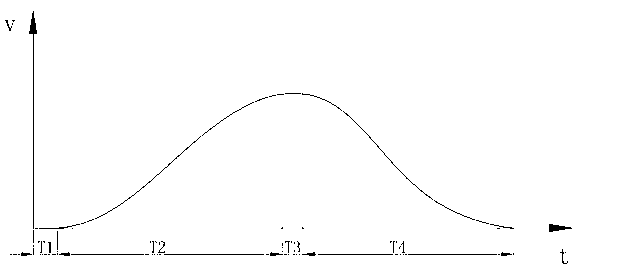

[0018] A planetary gear linkage combined paper transfer device, comprising a four-bar linkage device and a planetary gear mechanism; the four-bar linkage arrangement includes a driving gear 1, a crank 2, a connecting rod 3, and a rocker 4; the planetary gear mechanism includes a sun Wheel 5, planetary gear 6, and ring gear 7; the crank 2 is fixed on the eccentricity of the driving gear 1 and rotates with the movement of the driving gear 2; the rocker 4 is a tie rod in the planetary gear mechanism and is connected to the sun at the same time wheel 5 and planetary gear 6; the number of teeth and the modulus of the driving gear 1 are equal to the number of teeth and the modulus of the ring gear 7 in the planetary gear mechanism; When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com