Active maglev electromagnetic catapult

A magnetic levitation and catapult technology, which is applied in the direction of launch/drag transmission, can solve the problem of not eliminating the rolling friction resistance between the aircraft wheel and the deck, and achieve the effects of improving positioning accuracy and ejection speed, adjustable damping, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

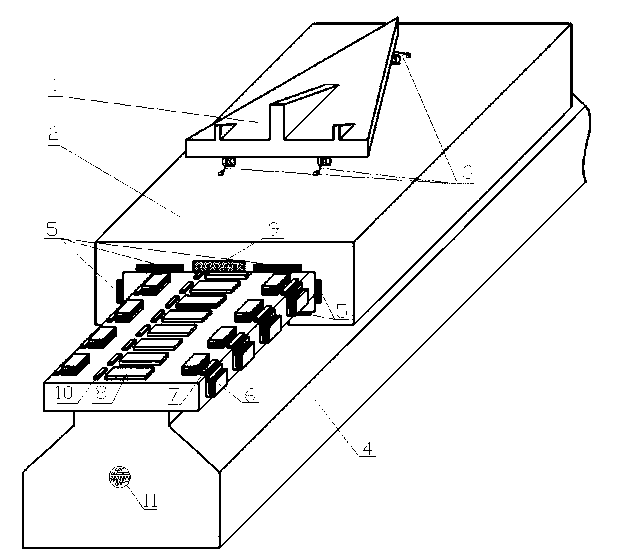

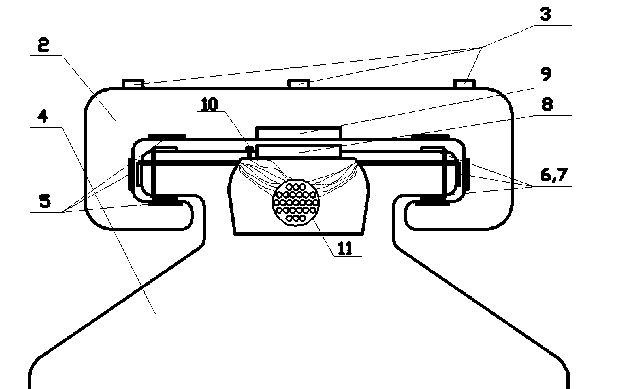

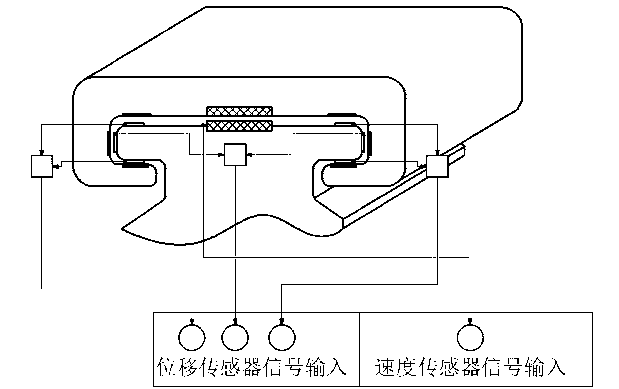

[0028] see figure 1 and figure 2, the active magnetic levitation electromagnetic catapult includes a carrier-based aircraft 1 to be ejected and an ejection platform 2 for placing the carrier-based aircraft and being set on the guide rail, and is characterized in that it also includes a connecting part connected to the carrier-based aircraft 1 on the ejection platform 2 3. An ejection base 4 with a magnetic levitation guide rail, a magnetic material 5 embedded on the ejection platform 2, corresponding to the magnetic material 5 and fixed on the two sides of the magnetic levitation guide rail of the ejection base 4, on the bottom and on the side, and controlled by the control system. And the guide electromagnet 6 and the inductive sensor 7 that is arranged next to the electromagnet 6 to detect the displacement change of the ejection platform, and the linear ejection motor primary winding 8 located on the center line of the top surface of the magnetic levitation guide rail of th...

Embodiment 2

[0030] see figure 1 , the active magnetic levitation electromagnetic catapult includes a carrier aircraft model 1 to be ejected, and an ejection platform 2 for placing the carrier aircraft. The connecting part 3 of the carrier aircraft, which makes the ejection platform firmly connected during ejection and drives the ejection operation of the carrier-based aircraft, and the ejection base 4 with a magnetic levitation guide rail, and the magnetic levitation guide rail on it makes the relative movement between 2 and 4 realize no mechanical Contactless frictionless magnetic levitation technology support, so that the carrier-based aircraft on the ejection platform is only subject to air resistance, the magnetic material 5 embedded on the ejection platform, fixed on the guide rail and controlled by the control system The electromagnet 6 is used to detect the displacement of the ejection platform The variable inductive sensor 7, the primary 8 and secondary 9 of the linear ejection mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com