Preparation method of graphene nanometer material automobile finish

An automobile topcoat and nanomaterial technology, which is applied in the field of preparation of graphene nanomaterial automobile topcoats, can solve the problems of additional cost, complexity of painting links, poor performance, and reduced corporate profits and efficiency. Achieve the effect of improving production efficiency and consumer purchasing power, low cost, and complete functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

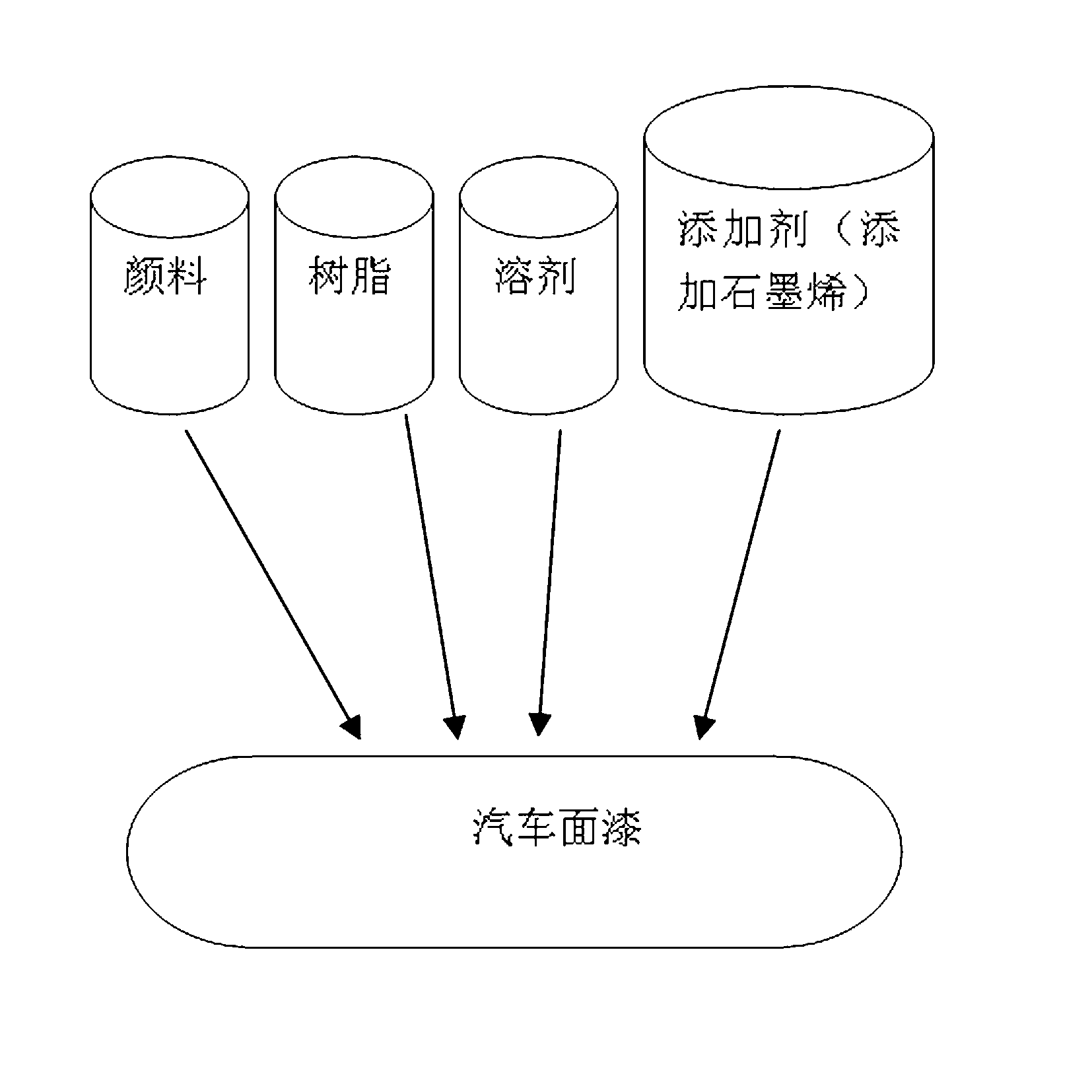

[0020] according to figure 1 Shown, the preparation method of a kind of graphene nano-material automobile finish of the present invention, the method has the following steps:

[0021] 1) Preparation of graphene powder;

[0022] Concentrated H was added to the graphite in a certain proportion 2 SO 4 , KMnO 4 , H 2 0 and H 2 o 2 Wait for reagents, mix evenly and maintain a certain temperature and time, then add dilute HCl to wash and stand still, take out the precipitate, wash to neutral, dry, expand and restore, and finally get black nano-graphene powder;

[0023] 2) Preparation of nano-graphene slurry;

[0024] Add nano-graphene powder into the solution of absolute ethanol and dispersant and stir, adjust to a suitable pH value, and finally use high-speed disperser and ball mill to disperse for a certain period of time to obtain nano-graphene dispersion;

[0025] 3) Preparation of graphene nanomaterial automotive topcoat;

[0026] The raw material nano-graphene slurry,...

Embodiment

[0031] Step 1: preparation of graphene powder;

[0032] Mix 50.0g graphite with 1-5L 98% H 2 SO 4 Mix and stir well at 20 0 Slowly add 150.0-300.0g KMnO at C 4 , maintained for 12-24h, and then added a certain amount of H 2 0, the temperature and time were maintained at 80-90 0 C, 0.5-1h, then add 250-500ml H 2 o 2 (concentration 30%), finally with HCl and H 2 Wash with O, take the precipitate to neutrality, dry, expand and reduce at high temperature, and obtain black nano-graphene powder. (The above ratio can be scaled up in equal proportions)

[0033] Step 2: preparation of nano-graphene slurry;

[0034] First, mix absolute ethanol and dispersant evenly, then add nano-graphene powder into it, stir at a certain speed, add a pH regulator to adjust to a suitable pH value, and finally use a high-speed disperser and a ball mill to disperse for a certain period of time A nano-graphene dispersion is obtained, wherein the nano-graphene powder is the nano-powder prepared in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com