Startup passivation method of hydrocracking catalyst

A hydrocracking and catalyst technology, applied in hydroprocessing process, petroleum industry, hydrocarbon oil treatment, etc., to achieve the effect of reducing investment, rational utilization of resources, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

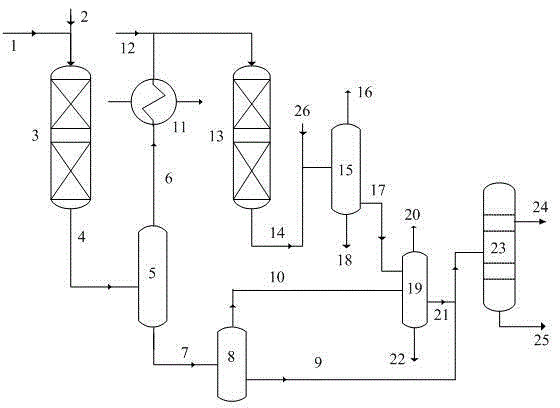

[0027] Such as figure 1 As shown, taking high-nitrogen diesel oil as the passivation feedstock oil as an example, a kind of implementation of the hydrocracking catalyst start-up passivation method of the present invention is as follows:

[0028] After the sulfidation of the catalyst is completed, reduce the inlet temperature of the hydrotreating reactor to 220-270°C, and lower the inlet temperature of the hydrocracking reactor to 150-205°C. Diesel feedstock 1 with a relatively high nitrogen content is mixed with hydrogen 2, and then enters the hydrogenation pretreatment reactor 3 with an inlet temperature of 220-270°C, and then slowly increases the inlet temperature of the hydrotreating reactor to control the reaction effluent 4 The nitrogen content is low, generally less than 10μg / g. During this process, the liquid phase 7 obtained after the reaction effluent 4 passes through the hot high-pressure separator 5 enters the hot low-pressure separator 8, and the gas phase 10 obtai...

Embodiment 1

[0031] use figure 1 process shown. After the sulfidation of the catalyst is completed, the inlet temperatures of the refining reactor and the cracking reactor are lowered to 220° C. and 180° C. respectively.

[0032] Introduce coked diesel oil into the refining reactor, increase the temperature of the refining reactor at a rate of 15°C / h, and the refined effluent directly enters the thermal high fraction; when the nitrogen content of the refined effluent is 37 μg / g, keep the refining inlet temperature constant , and at the same time maintain the inlet temperature of the cracking reactor not higher than 205°C through the heat exchange process, waiting for the breakthrough of ammonia. Among them, after 4 hours of oil introduction, water is injected into the inlet of the cold high fraction.

[0033] When the ammonia concentration in the water of the separation system reaches 0.5wt%, the inlet temperature of the cracking reactor is raised at a rate of 6°C / h through heat exchange...

Embodiment 2

[0037] use figure 1 process shown. After the sulfidation of the catalyst is completed, the inlet temperatures of the refining reactor and the cracking reactor are respectively lowered to 260°C and 190°C.

[0038] Introduce coker wax oil into the refining reactor, increase the temperature of the refining reactor at a rate of 15°C / h, and the refined effluent directly enters the separation system; when the nitrogen content of the refined effluent is 369 μg / g, keep the refining inlet temperature constant , and at the same time maintain the inlet temperature of the cracking reactor not higher than 205°C through the heat exchange process, waiting for the breakthrough of ammonia. Among them, after 4 hours of oil introduction, water is injected into the inlet of the cold high fraction.

[0039] When the ammonia concentration in the water of the separation system reaches 0.5wt%, the inlet temperature of the cracking reactor is increased at a rate of 6°C / h through heat exchange, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com