Efficient energy-saving environment-friendly oil nozzle

A high-efficiency, energy-saving, fuel-injection technology, which is applied in the fields of engines and steam turbines, can solve the problems of inability to control and adjust the fuel supply in a large range, and inability to meet the needs of development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

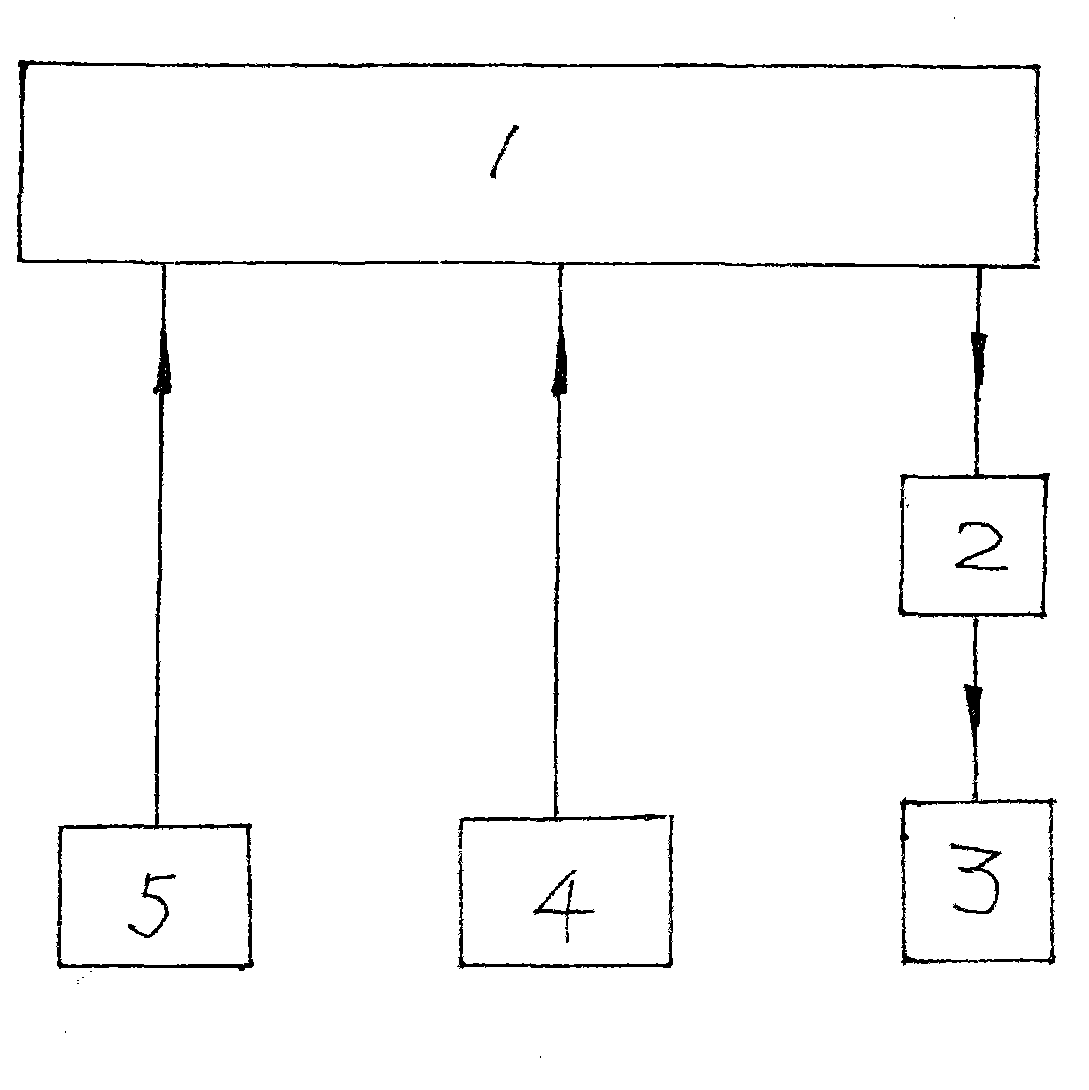

[0005] A high-efficiency, energy-saving and environment-friendly fuel injection nozzle. In the case of pure oxygen as a combustion aid, there are dozens of oil delivery pipes from the oil pump to the fuel injection nozzle. There is a solenoid valve on each oil delivery pipe. The solenoid valve is controlled by a microcomputer. There are also dozens of fuel injectors, and each fuel delivery pipe is connected to a fuel injector. The microcomputer captures the oxygen pressure and temperature parameters from the engine and steam turbine intake pipes through sensors, and combines the type, pressure and viscosity parameters of the fuel at the outlet of the oil pump delivery pipe. , after microcomputer matching processing, according to the standard that the fuel-oxygen ratio is excessive oxygen, select the best matching fuel supply ratio, control the quantity of fuel injected by the injector, issue instructions, and inject fuel according to the best ratio to achieve excess pure oxygen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com