Delay assembly capable of resisting temperature difference

A combination of components and temperature difference technology, applied in the direction of weapon accessories, fuzes, blasting, etc., can solve the problems of warping and deformation of the cap, unstable delay time, and shortened delay time, etc., to achieve small environmental temperature effects, reasonable structural design, and manufacturing The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

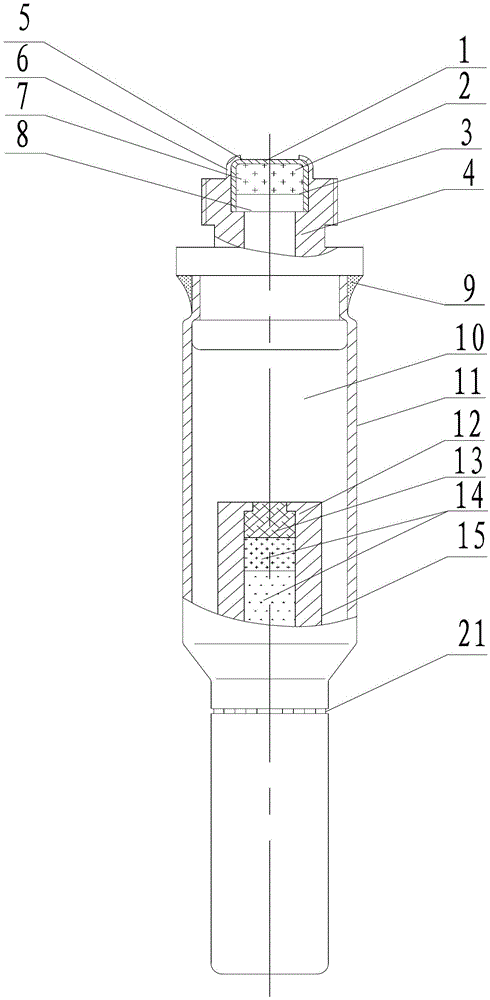

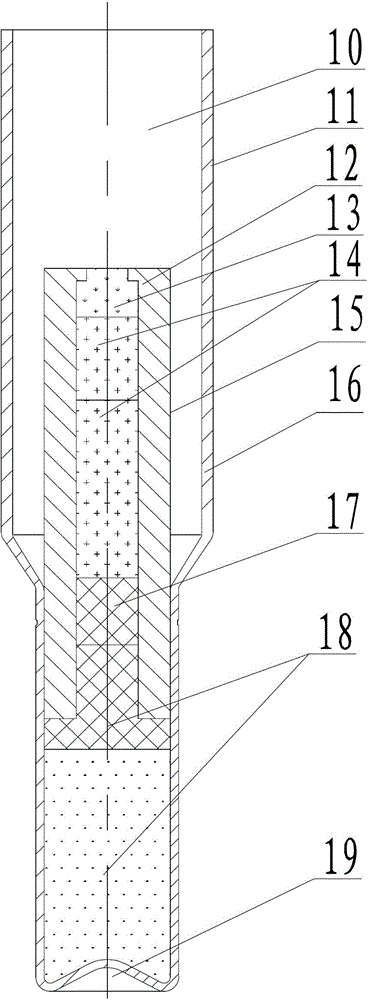

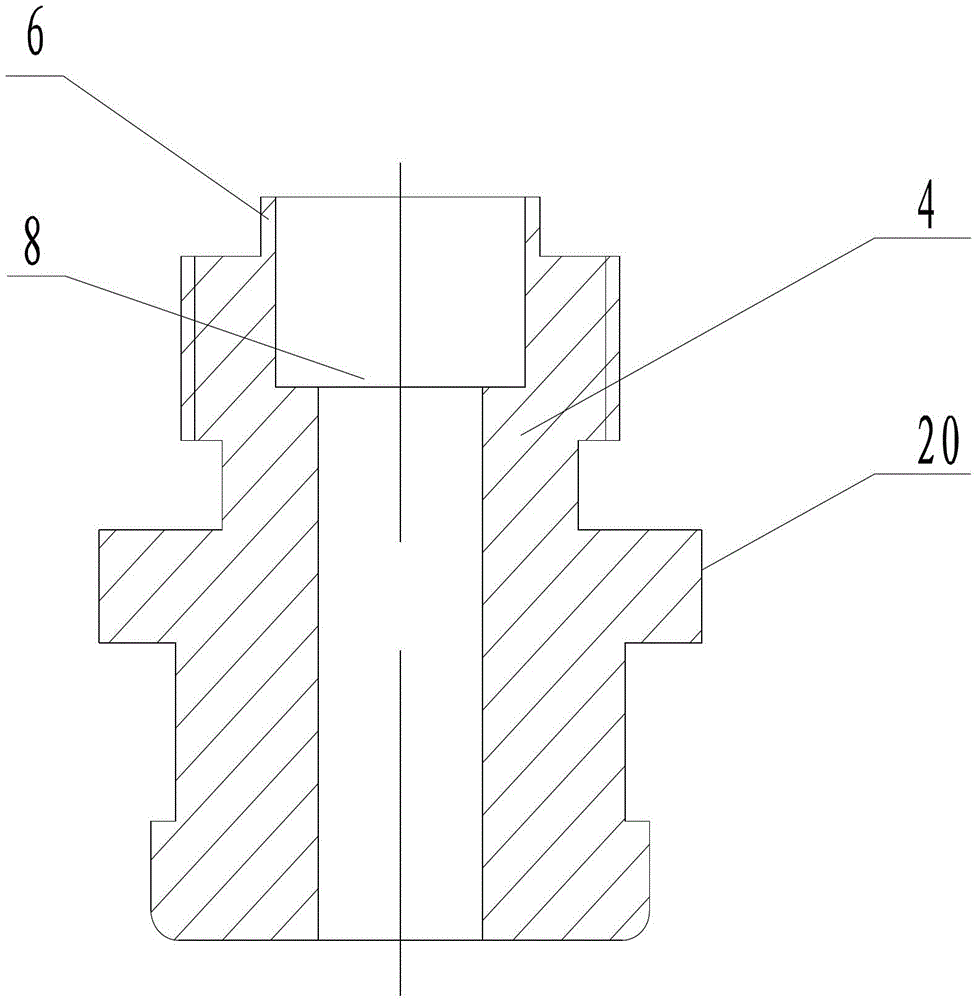

[0018] The present invention will be further described below in conjunction with the accompanying drawings: the ignition element used to ignite the ignition powder 13 is formed by the flash cap shell 1, the percussion charge 2 and the cover sheet 3, and the ignition element hits the flash cap 7, wherein the cover sheet 3 plays a role in fixing the medicament and preventing it from colliding with the flash cap 7 be affected with the effect of being affected with damp; Delay tube case 12, ignition powder 13, delay charge 14, priming charge 17 and explosive 18 form delay time detonation element delay initiation part 15, delay time is mainly controlled by delay charge 14; Detonator shell 16 and Explosives 18 form detonator 19, and delayed detonator 15 and detonator 19 are formed the delayed detonator 11 that delays detonation function. Different medicaments are assembled into impact cap 7, delayed detonator 15 and delayed detonator 11 to form monomers with different functions by us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com