Portable sampling device for deep in situ soil and usage method thereof

A sampling device and in-situ soil technology, applied in the direction of sampling devices, etc., can solve problems such as easy tilting, easy damage of drill bits and drill pipes, fertilizer pollution, etc., and achieve the effect of firm sampling device, clean connecting rod, and cleaner sampling device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

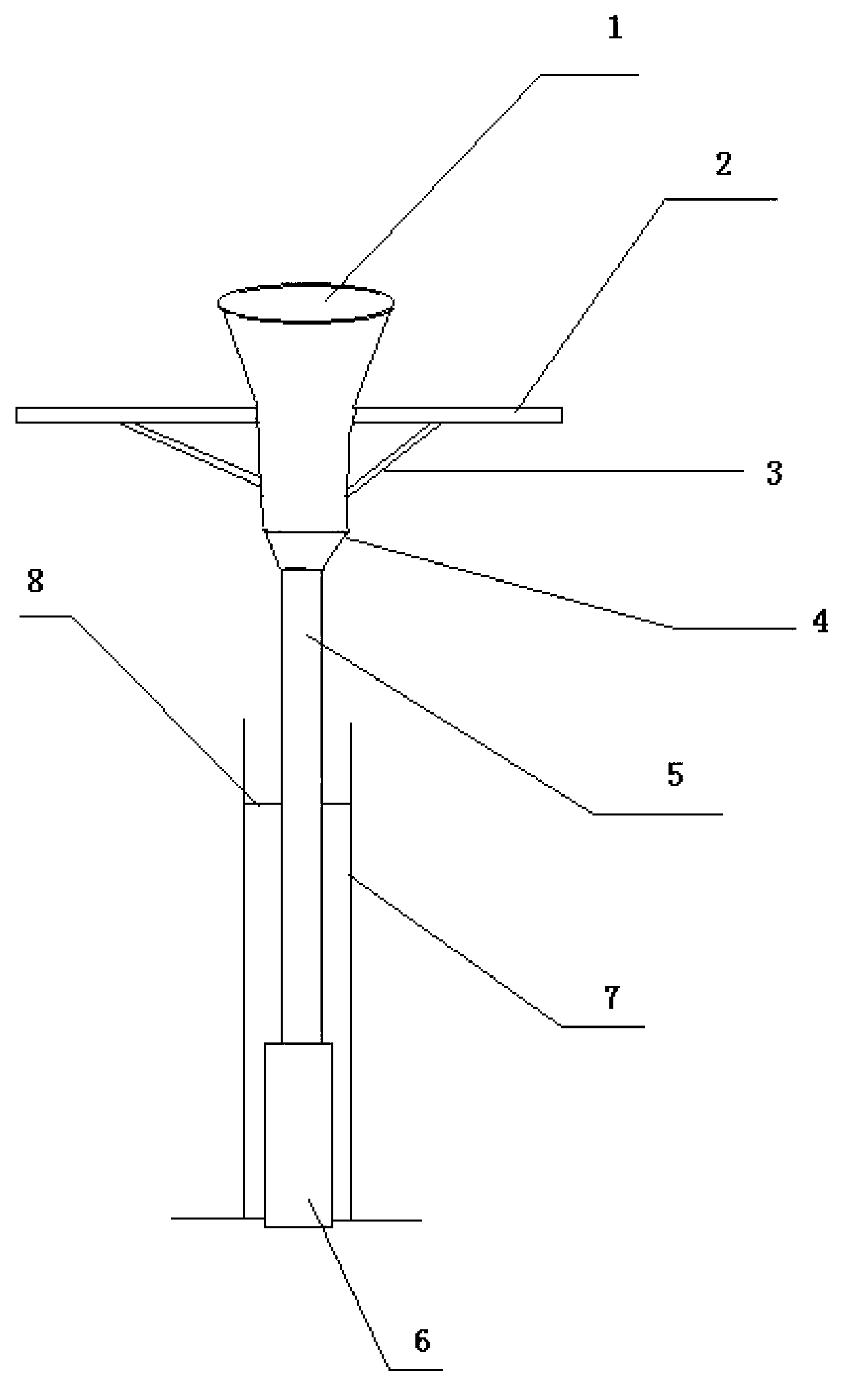

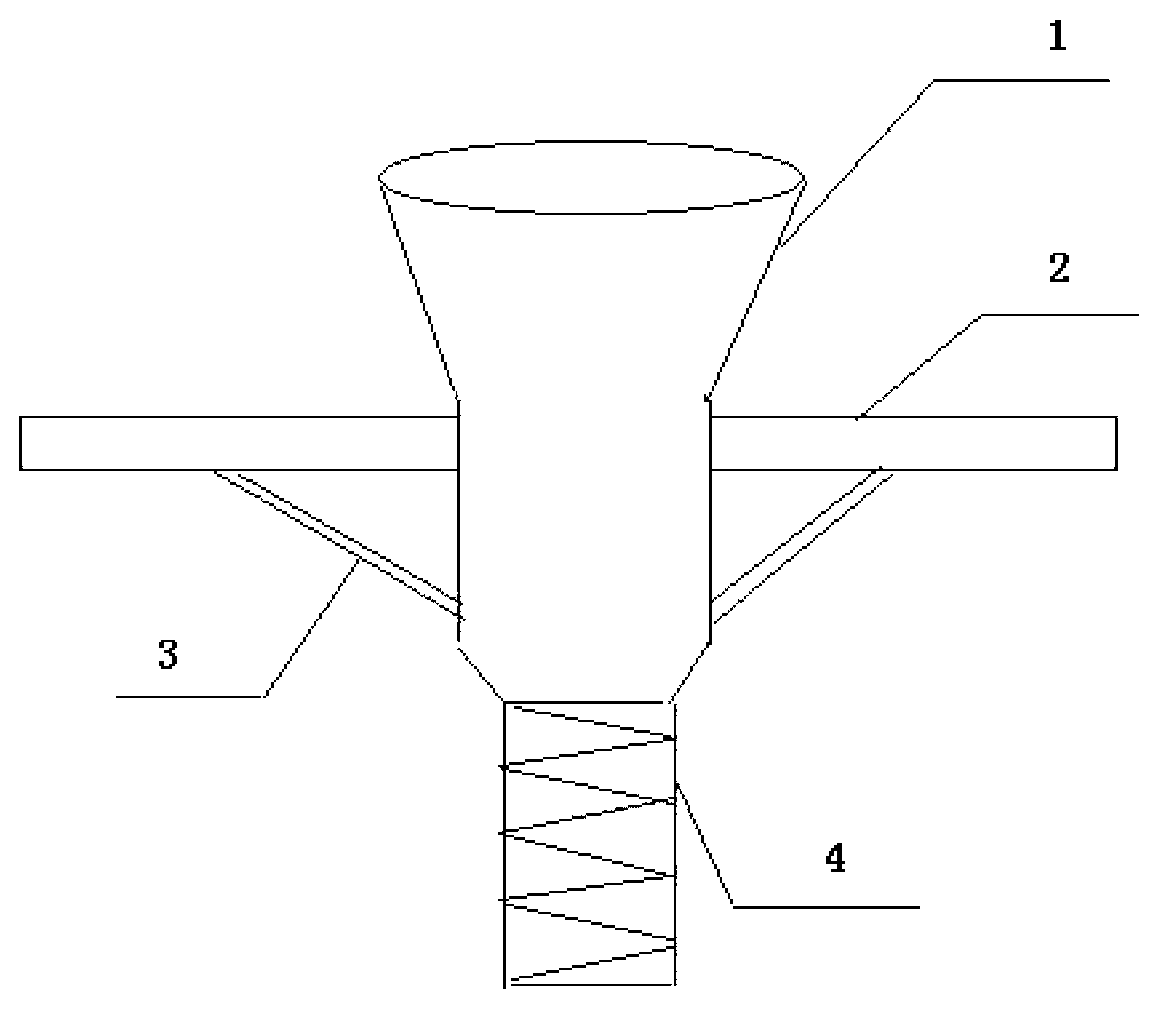

[0047] A portable deep in-situ soil sampling device, the structure is like Figure 1-8 As shown, the hammering handle 1, threaded joint 4, connecting rod 5, and sampling head 6 are sequentially connected from top to bottom. The hammering handle 1 is fixedly connected to the threaded joint 4, and one end of the connecting rod 5 is threadedly connected to the threaded joint 4. The other end is threadedly connected to the sampling head 6. A cross grip rod 2 passing through the hammer handle 1 is provided in the middle of the hammer handle 1. The two ends of the cross grip rod 2 are located at two ends of the hammer handle 1. On the other hand, two reinforcing brackets 3 are respectively provided on both sides of the hammering handle 1. One end of the reinforcing bracket 3 is fixed to the hammering handle 1, and the other end is fixedly connected to the cross grip rod 2. The hammering handle 1 , Two reinforcing brackets 2 form a triangle. The hammering handle 1 is in the shape of a...

Embodiment 2

[0054] A portable deep in-situ soil sampling device as described in Example 1, the difference lies in:

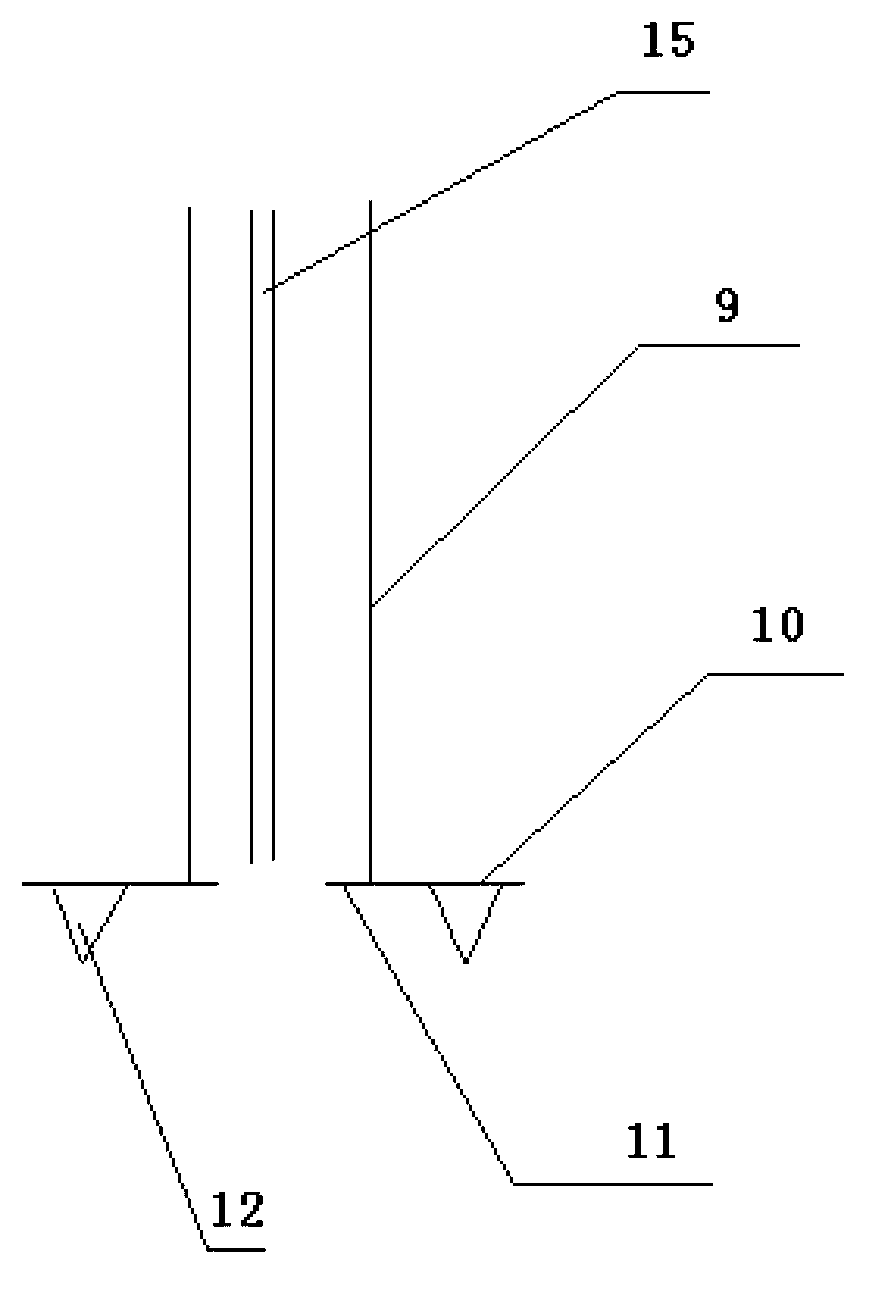

[0055] The horizontal plate 10 forms a square horizontal plate on the outer periphery of the bottom end of the cylindrical sleeve 9, and the structure is as Figure 8 Shown.

[0056] The height of the sampling head is 35 cm, the side wall of the sampling head 6 is provided with an axial soil pouring hole 19, the height of the soil pouring hole is 33 cm, and the width is 20 mm.

Embodiment 3

[0058] A method for sampling using a portable deep-layer in-situ soil sampling device as described in Example 1, including the following steps:

[0059] (1) Select a sampling point with a flat surface, erect the straightening device vertically on the sampling point, insert the protruding tip at the bottom of the horizontal plate into the soil layer and make the bottom of the horizontal plate close to the ground;

[0060] (2) According to the sampling depth, adjust the position of the straightening device to be fixed on the connecting rod, and align the end of the limiting chuck with the groove of the side wall of the cylindrical sleeve, and extend the sampling head and the connecting rod into the cylindrical In the sleeve, the sampling head is aligned with the hole in the center of the ring block;

[0061] (3) Apply pressure to the hammering handle, and the sampling head penetrates the perforation of the ring block and enters the soil layer. As the sampling head gradually enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com