Defect detecting device used for air-blowing mini-type optical cable jacket surface

A defect detection and optical cable technology, which is applied in the direction of measuring device, color/spectral characteristic measurement, mechanical diameter measurement, etc., can solve the problems of construction influence, difficult inspection, etc., achieve high accuracy, convenient use and installation, and avoid detection omissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

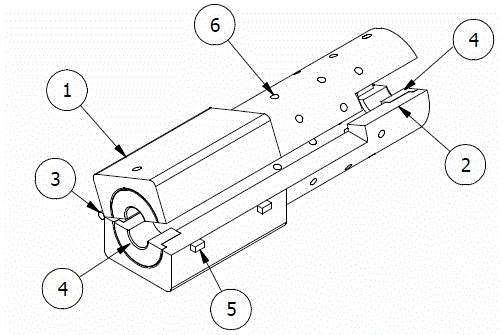

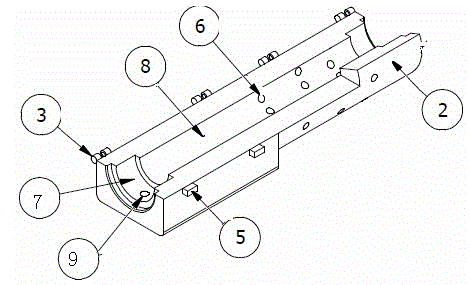

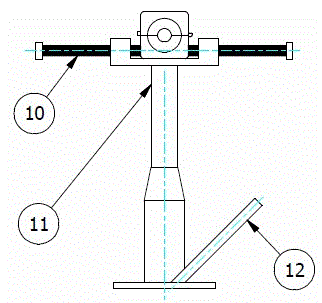

[0018] It includes a detection seat cover 1, the detection seat cover is composed of upper and lower seat covers that are opened and closed in half, the front section of the detection seat cover is rectangular, the middle and rear section is circular, and the upper and lower seat covers The rear ends of the rear end are respectively provided with corresponding positioning pits and bosses 2, which are used for positioning after the upper and lower seat covers are combined, and the middle of the upper and lower seat covers is provided with a cable through hole 8, and the upper and lower seat covers One side of the seat cover is hinged by 3 tensioners, 3 to 4 tensioners are installed at intervals, and a sizing die 4 that opens and closes in half is installed at the front and rear ends of the upper and lower seat covers. The combined sizing die is composed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com