Failure prediction method facing to numerically-controlled machine tool

A technology for CNC machine tools and fault prediction, which is applied in program control, computer control, general control system, etc. It can solve uncertain information processing and theoretical modeling technology, which needs further research, is not suitable for medium and long-term prediction, and has slow performance changes. and other problems, to achieve good application prospects, improve fault prediction capabilities, and have less prior knowledge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The implementation of a fault prediction method for numerically controlled machine tools according to the present invention will be described in detail below with reference to the drawings and embodiments.

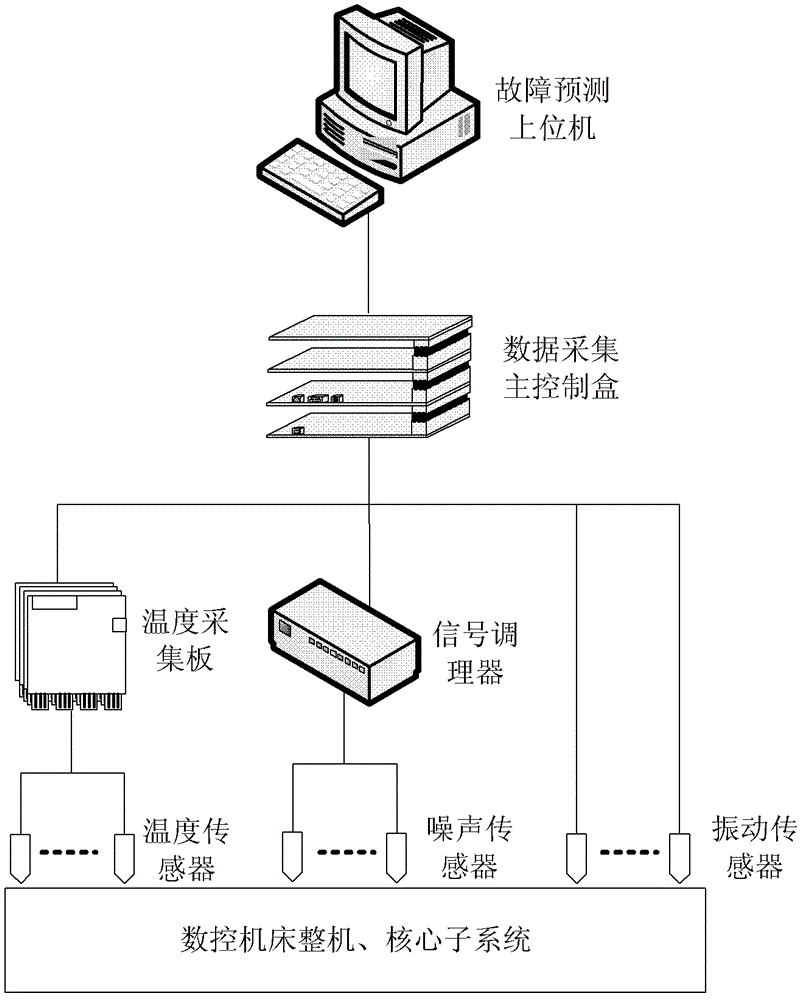

[0043] Such as figure 1 Shown is the structural diagram of the fault prediction system applied by the method of the present invention. In this figure, the temperature, noise, and vibration sensors are used to collect the machine tool operation status data of the CNC machine tool and the core subsystem. The temperature data is sent to the data acquisition main control box through the preliminary processing of the temperature acquisition board, and the noise data is sent through the preliminary processing of the signal conditioner. To the main control box of data acquisition, the vibration data is directly sent to the main control box of data acquisition, and the main control box of data acquisition performs unified denoising and filtering on the data of each sensor a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com