A fault prediction method, system, electronic device and readable storage medium

A fault prediction and failure technology, applied in design optimization/simulation, electrical digital data processing, instruments, etc., can solve problems such as economic losses, low maintenance costs, and reduced failure prediction effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

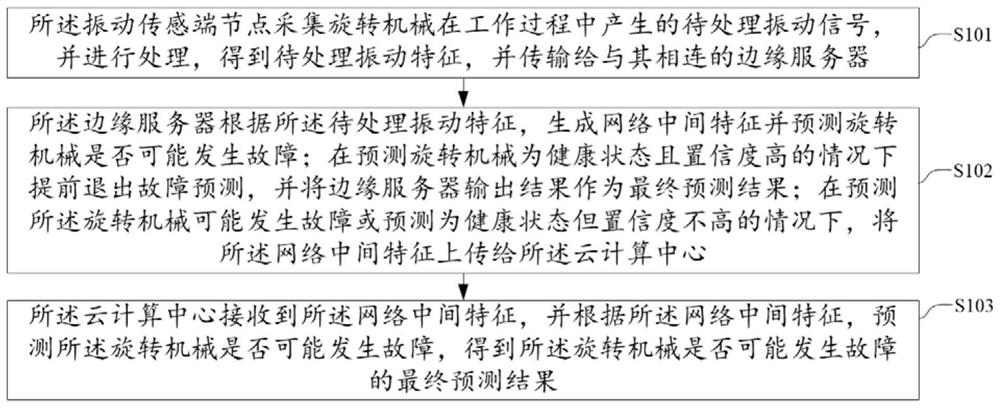

[0055] refer to figure 1 , figure 1 Shows a flow chart of the steps of a digital twin edge computing fault prediction method for rotating machinery in an embodiment of the present invention, the method is applied to an edge computing architecture system, and the edge computing architecture system includes a vibration sensor end node, an edge server As well as the cloud computing center, the method may specifically include the following steps:

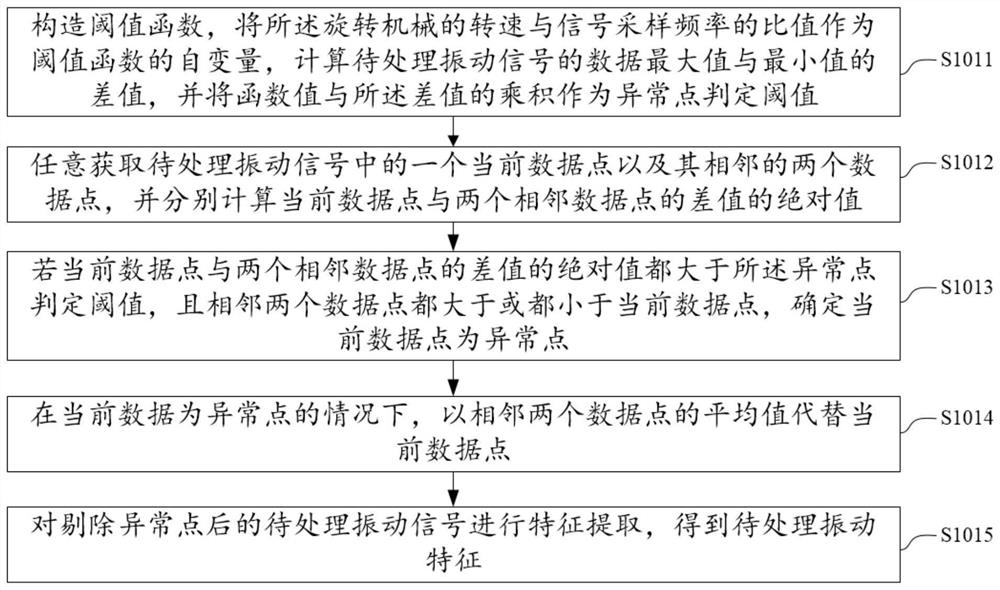

[0056] S101. The vibration sensing end node collects and processes vibration signals to be processed generated by the rotating machinery during operation to obtain vibration characteristics to be processed, and transmits the vibration signals to the edge server connected thereto.

[0057] Rotating machinery specifically refers to mechanical equipment objects that require fault monitoring in the predictive maintenance edge computing system, specifically referring to rotating mechanical parts such as gearboxes and bearings, and large-sca...

Embodiment 2

[0188] Based on the same inventive idea, Figure 7 A schematic diagram of functional modules of a digital twin edge computing fault prediction system for rotating machinery is shown, refer to Figure 7 As shown, the fault prediction system may include the vibration sensing end node, an edge server, and the cloud computing center;

[0189] The vibration sensing end node is used to collect the vibration signal to be processed generated by the rotating machinery during the working process, and process it to obtain the vibration characteristics to be processed, and transmit it to the edge server connected to it;

[0190] The edge server is used to generate network intermediate features and predict whether the rotating machinery may fail according to the vibration characteristics to be processed; if the rotating machinery is predicted to be in a healthy state and has a high degree of confidence, the fault prediction is exited in advance , and take the output result of the edge ser...

Embodiment 3

[0195] Based on the same inventive concept, Embodiment 3 of the present application provides an electronic device. The electronic device includes a memory, a processor, and a computer program stored in the memory and operable on the processor. When the processor executes the program, Embodiment 1 is implemented. Provided failure prediction methods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com