A capacitive touch screen with nano-silver electrodes

A technology of capacitive touch screen and nano-silver, which is applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve the problems of large parasitic capacitance value, influence of touch sensing sensitivity, reduction, etc., and achieve small plate capacitance value, reduction of overlapping parasitic capacitance, and improvement of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

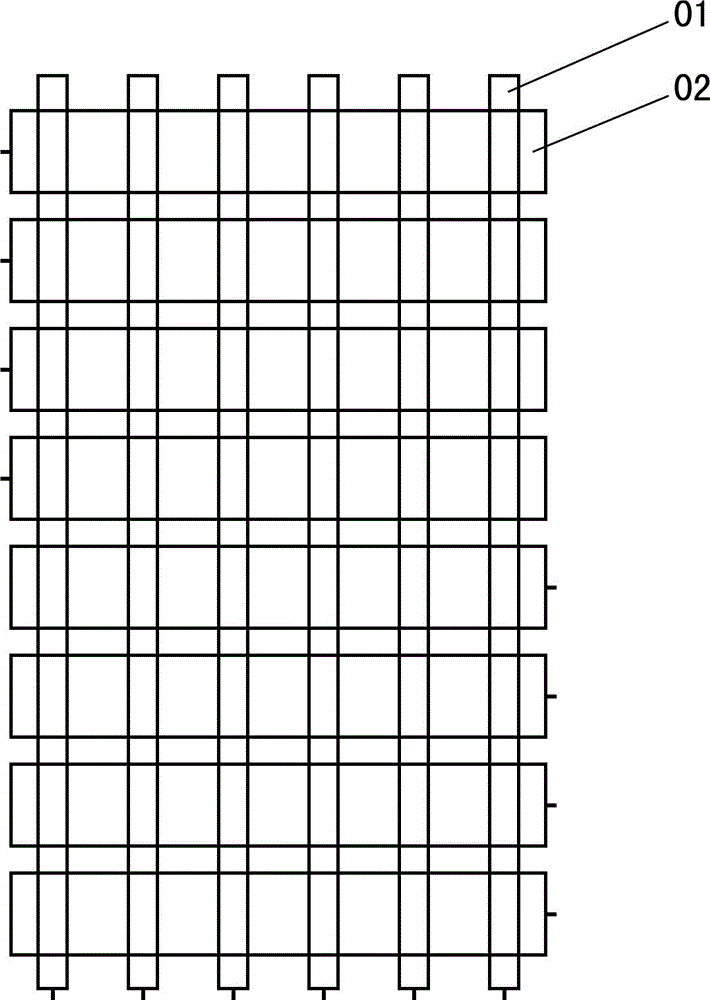

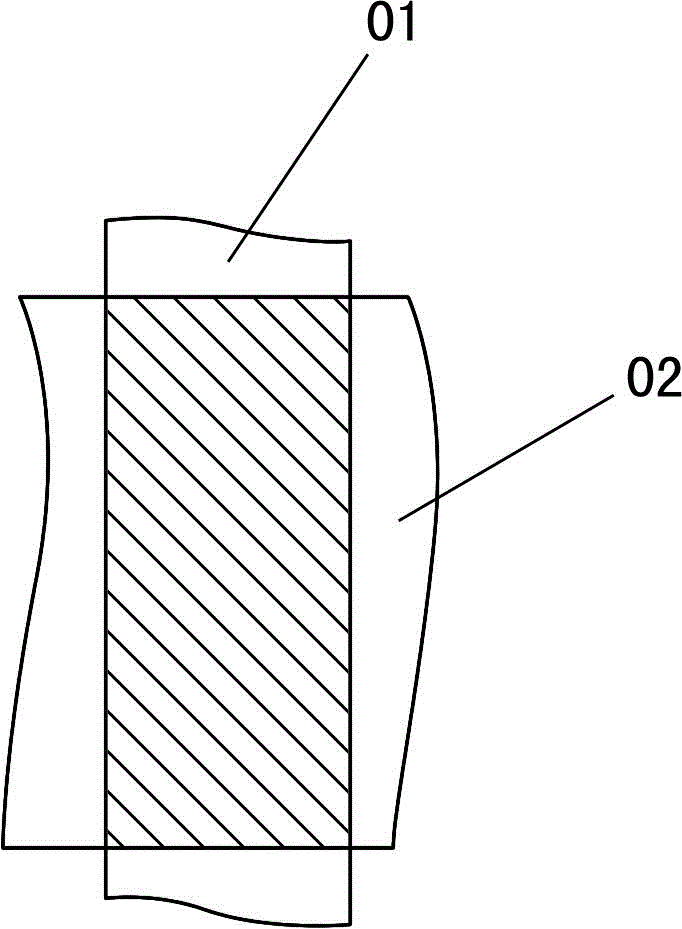

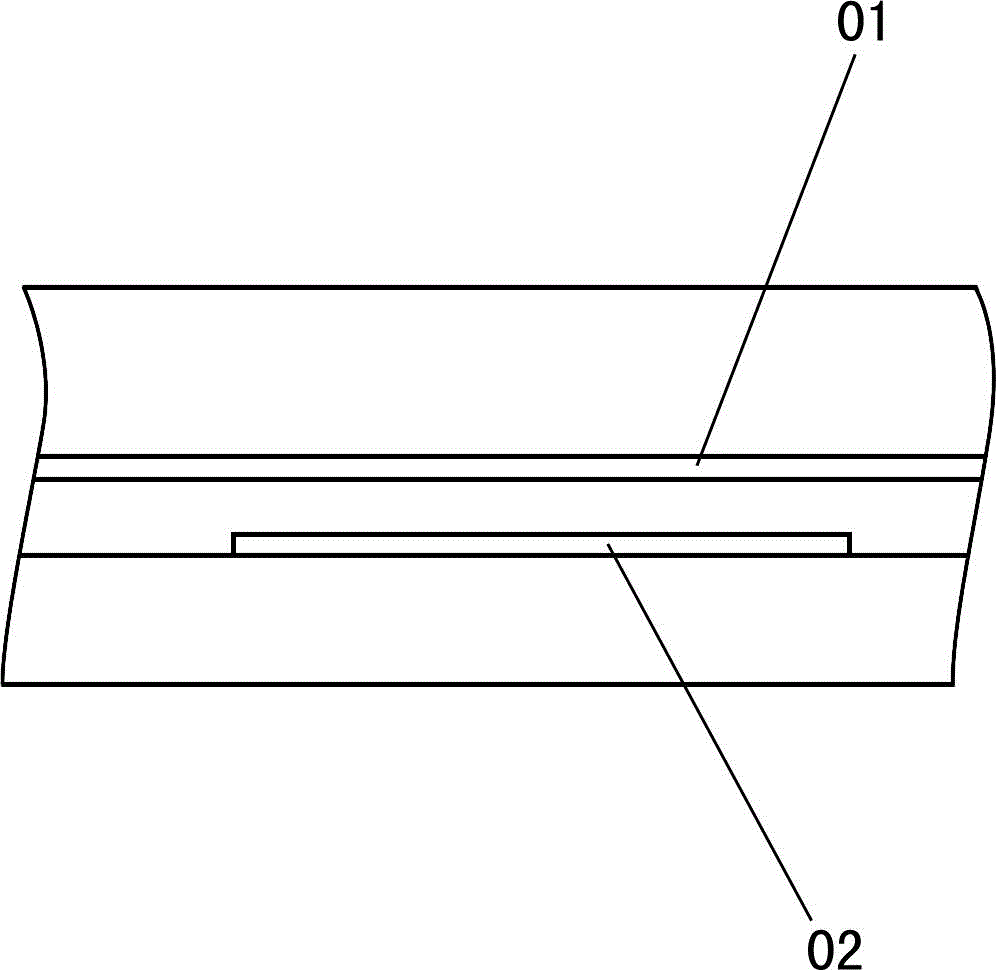

[0029] Such as Figure 4-8 As shown, this capacitive touch screen with nano-silver electrodes includes a transparent first substrate 1 of glass material, a transparent second substrate 2 of plastic material, and a first electrode layer 3 and a second electrode layer 4; wherein, the first electrode Layer 3 is a transparent conductive layer, which is formed on the inner side of the first substrate 1 by plating transparent conductive materials such as indium tin oxide, and is made into a plurality of first substrates extending along the first direction through a patterning process such as photolithography. An electrode 5; the second substrate 2 is provided with a plurality of second electrode arrangement areas 6 extending along the second direction, and each second electrode arrangement area 6 is provided with a plurality of grooves 7, and the plurality of grooves 7 are interlaced into a network, each groove 7 is filled with nano-silver conductive material 8, and the nano-silver ...

Embodiment 2

[0033] Such as Figure 9 As shown, in the case that other parts are the same as in the first embodiment, the difference is that: at the overlapping position of the first electrode 5 and the second electrode 10, the density of the nano-silver conductive thin wires 9 is set to be smaller than that of other positions. By at the overlapping position, the density of the groove 7 is set to be smaller than other positions, that is to say, the groove 7 at the overlapping position is set to be sparser, so that the density of the nano-silver conductive thin wire 9 at the overlapping position is set. In order to be smaller than other positions, the parasitic capacitance of the overlapping position is further reduced, and the sensitivity of the capacitive touch screen is further improved.

Embodiment 3

[0035] Such as Figure 10 As shown, in the case that other parts are the same as in the first embodiment, the difference is that the angle between the silver nano-conductive thin wires 9 and the second direction is 10° (5°-30° is acceptable). By setting the extension direction of all grooves 7 to have an included angle of 10° with the second direction, so that the included angle between the nano-silver conductive thin wires 9 in each groove 7 and the second direction is 10°, It is more applicable to the situation that the sub-pixels of the display matched with the capacitive touch screen are arranged in straight strips along the second direction, so as to prevent the second electrode 10 formed by the nano-silver conductive thin wire 9 from affecting all of the sub-pixels of a certain color in the display pixels. Color cast due to occlusion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com