Rectangular aluminum electrolytic capacitor module with heat dissipation surface and structure of module

A technology for aluminum electrolytic capacitors and heat dissipation surfaces, which is applied in the direction of electrolytic capacitors, capacitors, capacitor parts, etc., and can solve problems such as poor high temperature characteristics, low capacity density ratio, and low reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

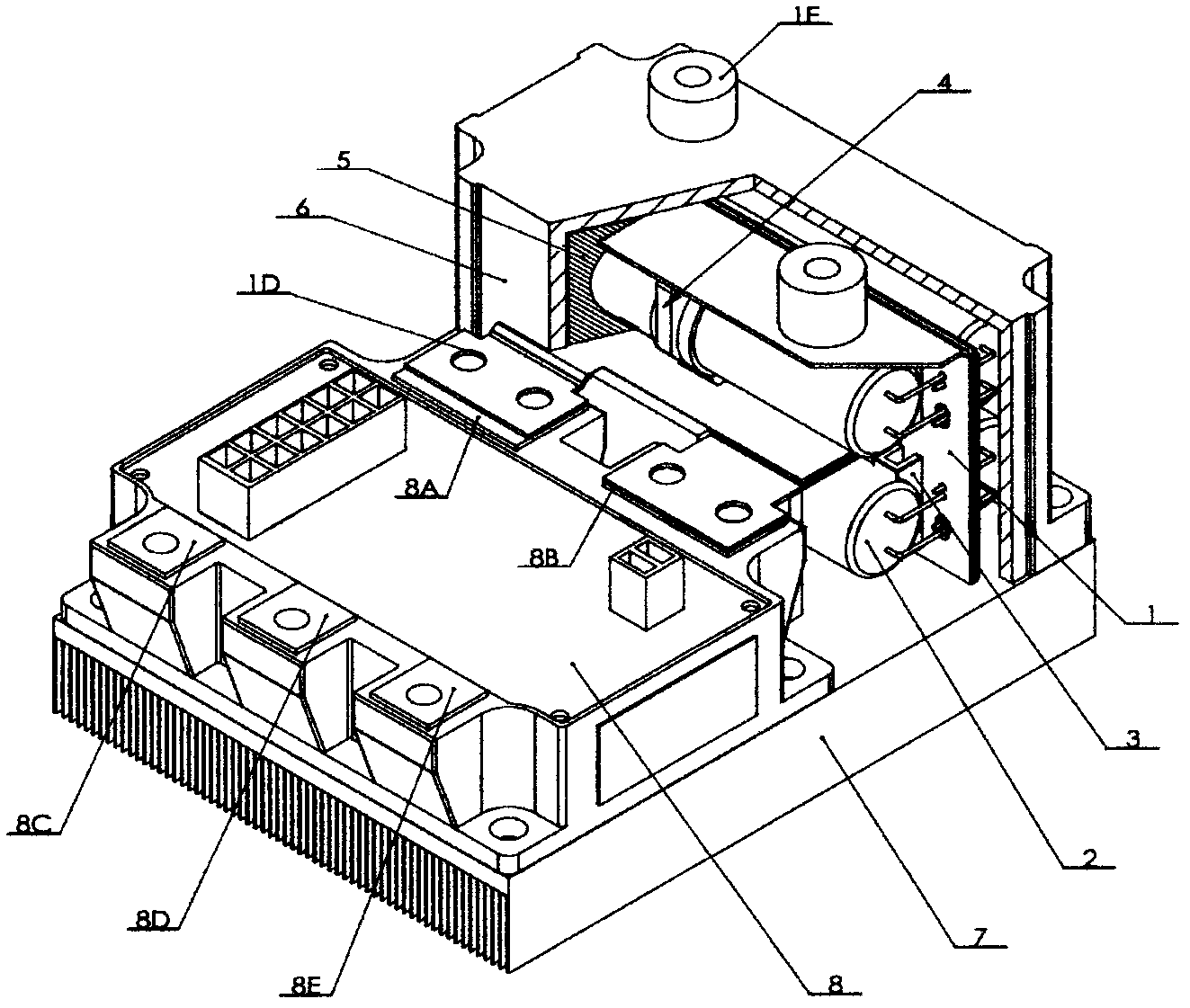

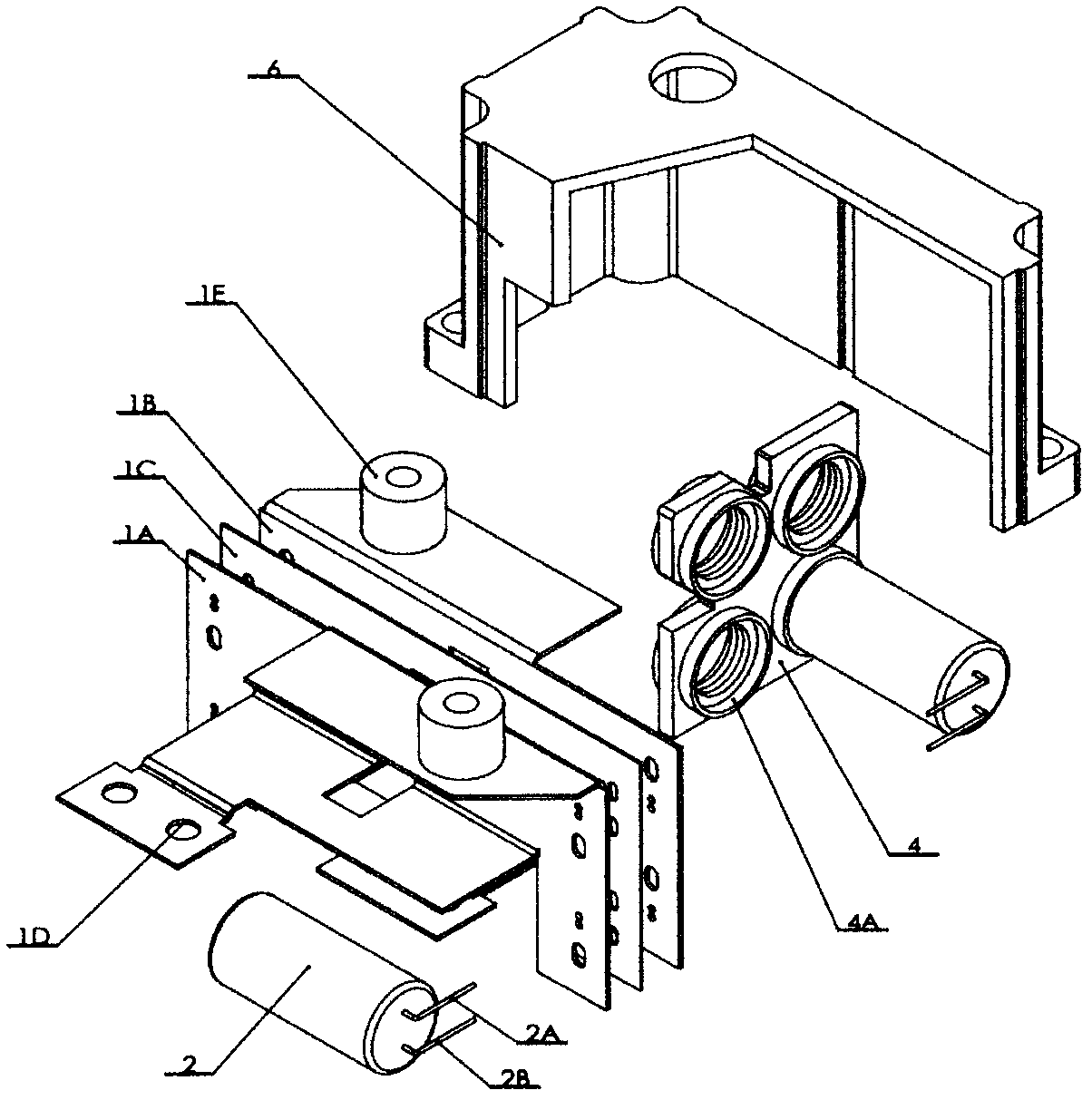

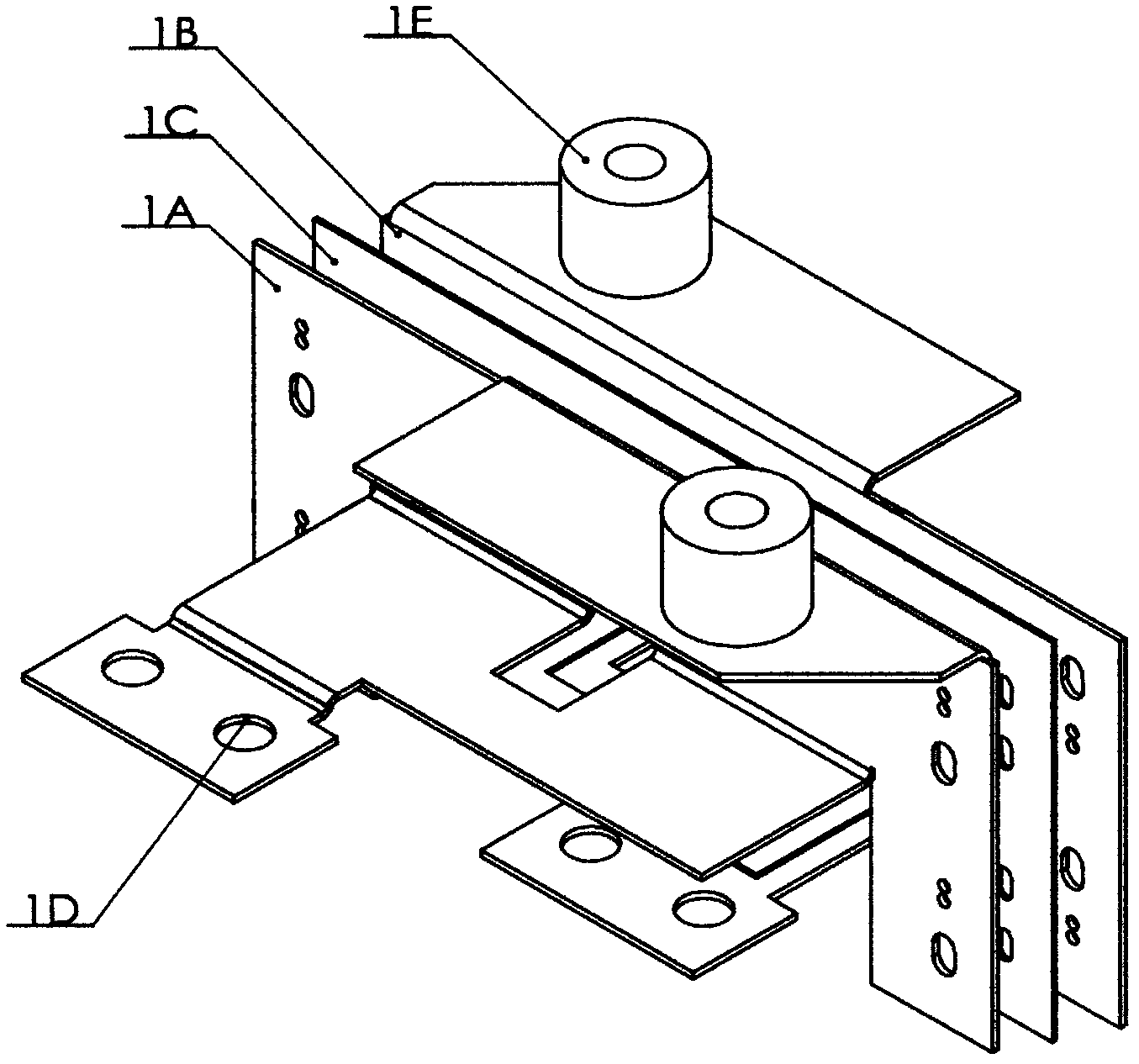

[0027] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

[0028] For the convenience of installing and connecting with the power MOSFET module 8 and the battery pack (such as figure 1 ), make the laminated busbar into a suitable shape, the positive busbar 1A and the negative busbar 1B are electrically insulated with the insulating layer 1C, and the two ends of the busbar are respectively provided with nut fixing columns 1E for connecting with the battery pack and with the power MOSFET module 8 Connecting terminal 1D (such as image 3 ).

[0029] The aluminum electrolytic capacitors 2 are arranged and distributed in the stacked bus bar 1. In order to reduce the structural volume and share the air guide slot 4, the electrolytic capacitor cylinder 2 is "lodged" on the fixed part 3 of the stacked bus bar 1 plane, that is, the aluminum electrolytic capacitor cylinder 2 is parallel to the plane axis of laminated bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com