Welding device for minimally invasive scalpel

A welding device and scalpel technology, applied in the field of medical equipment, can solve problems such as strict precision requirements and narrow knife heads, and achieve the effects of improving welding accuracy, improving welding accuracy and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

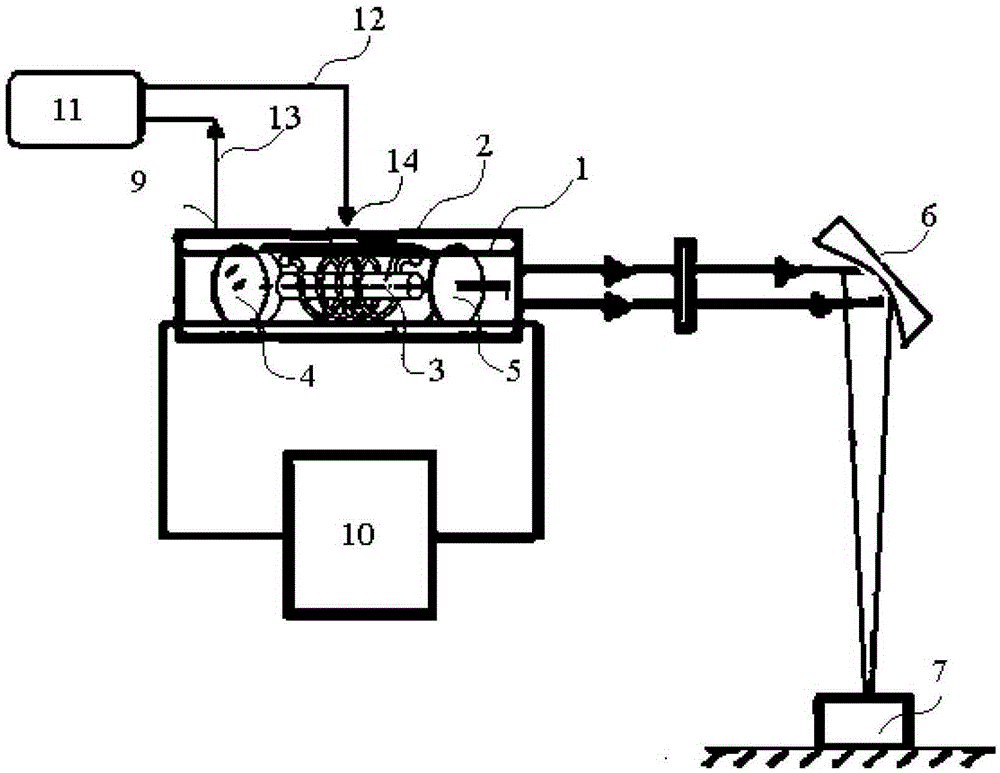

[0016] Embodiment: a welding device for a minimally invasive scalpel, comprising: a laser 1, used to generate a laser beam as a heat source, which includes a working substance area 3, a total reflection mirror 4 and a half reflection mirror 5 located in the housing 2 , the working substance area 3 is located between the total reflection mirror 4 and the half reflection mirror 5;

[0017] Concave reflector 6, used to change the transmission direction of the laser beam from the laser and form a spot;

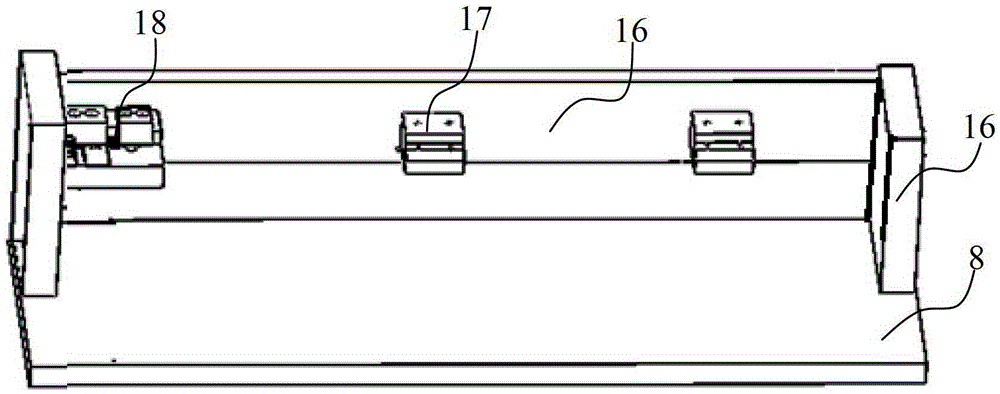

[0018] The workbench 7 is used to carry the minimally invasive scalpel to be processed. The workbench 7 is composed of a base plate 8, two side plates 15 and a pendant plate 16. The bottom ends of the two side plates 15 are respectively fixed on the On the left and right sides of the bottom plate 8, the pendant plate 16 is fixed between the two side plates 15, and the inner surface of the pendant plate 16 is fixed with at least one support seat 17 for placing a minimally invasive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com