Suspension arm welding and positioning device and method

A welding positioning and boom technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of increased transfer time, high purchase cost, and large workshop space occupation, so as to improve positioning accuracy and efficiency, avoid Potential safety hazards and the effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

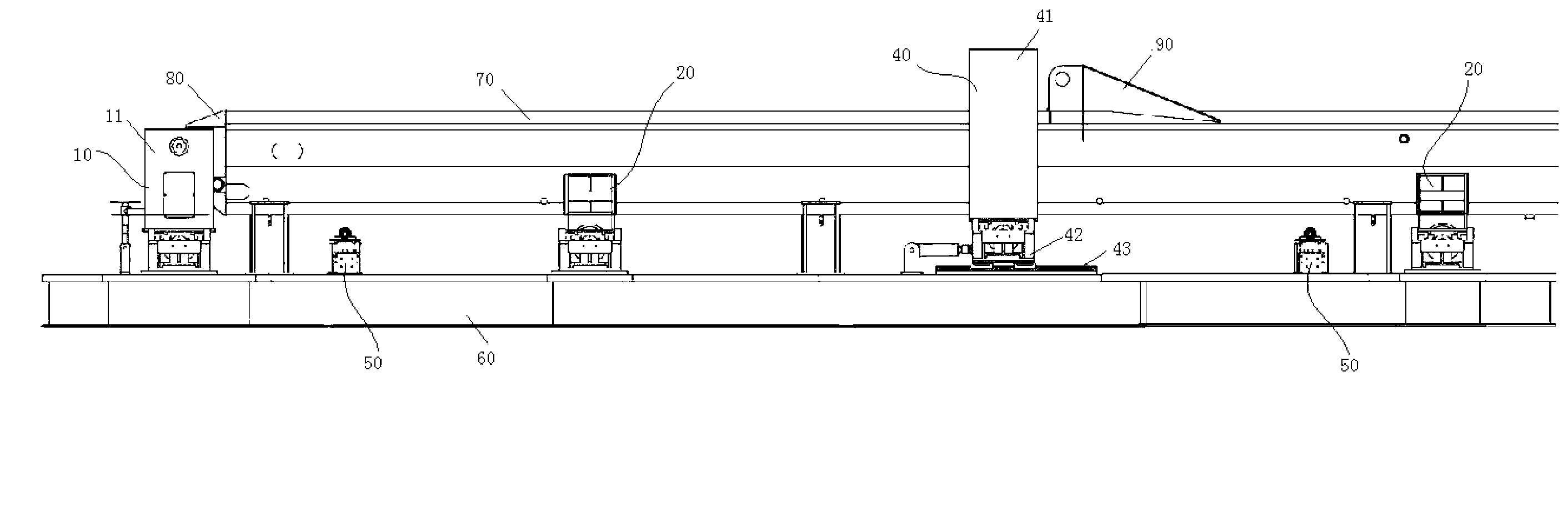

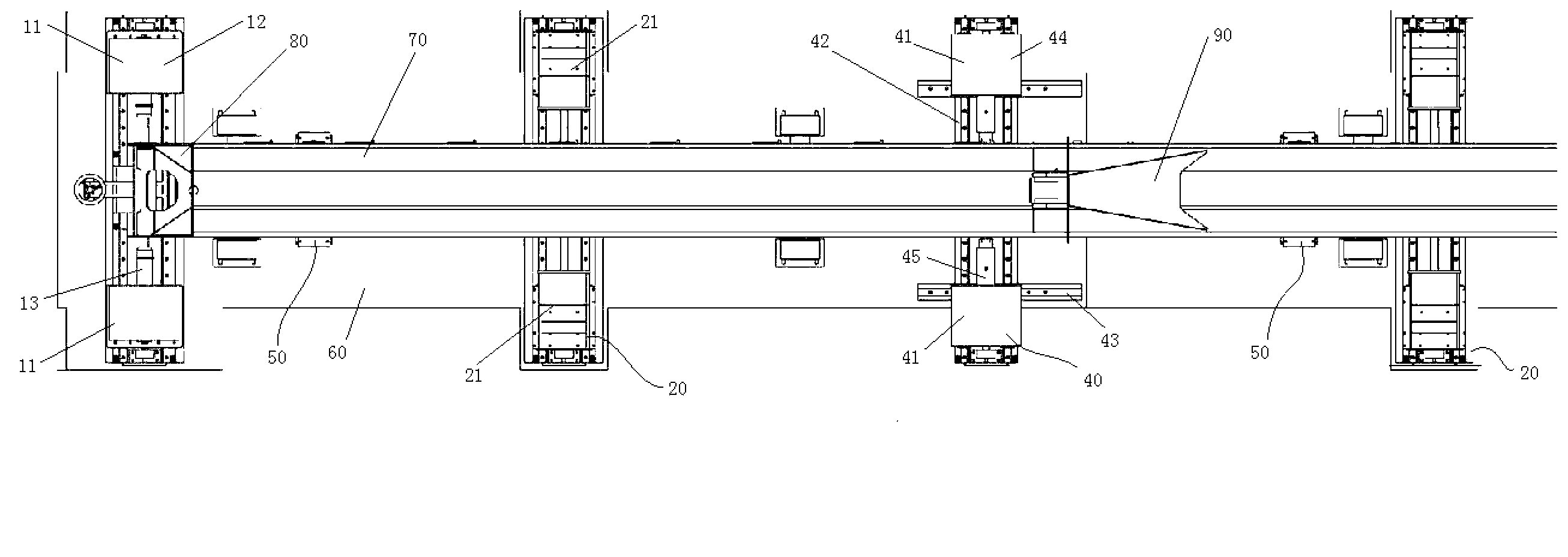

[0036] As a first aspect of the present invention, there is provided a welding positioning device for a boom, which can be adapted for basic boom welding.

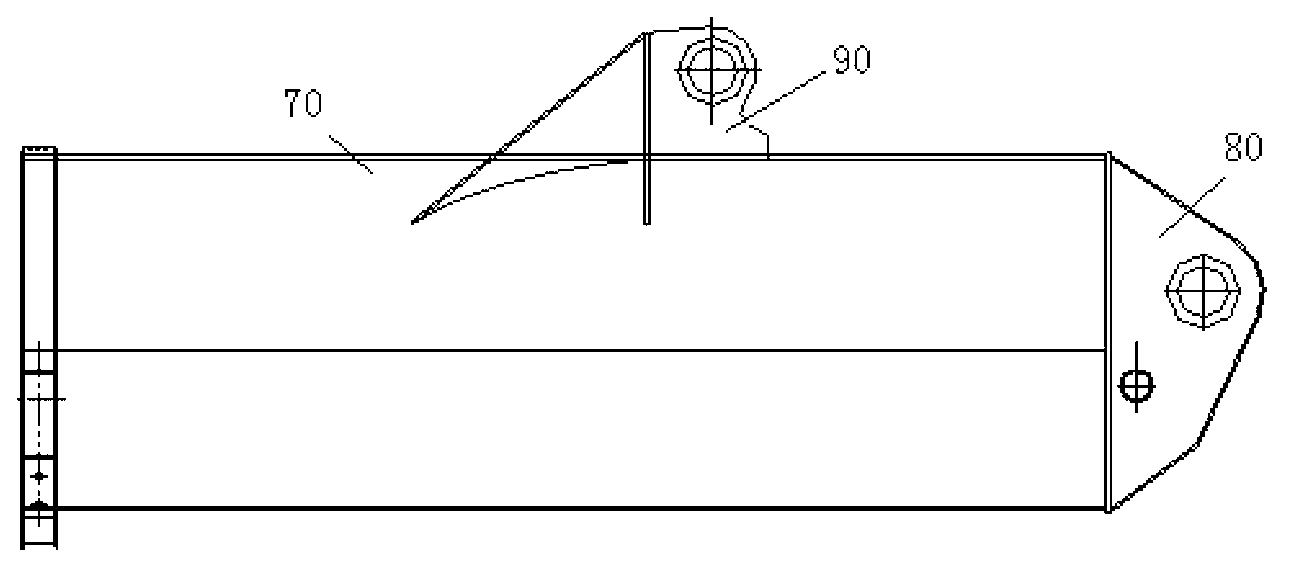

[0037] Such as Figure 2 to Figure 4 As shown, the welding positioning device includes: a tail positioning unit 10, including two tail positioning parts 11, the distance between the two tail positioning parts 11 is adjustable, and a tail positioning clamp is formed between the two tail positioning parts 11 Space; the barrel positioning unit 20 includes two splints 21 , the distance between the two splints 21 is adjustable, and a barrel positioning and clamping space is formed between the two splints 21 .

[0038] During welding, the boom tail 80 that has been processed in advance is clamped in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com