Die with heating device

A heating device and mold technology, applied in the field of molds for thermoplastic processes or thermosetting processes, can solve the problems of high equipment cost, high power consumption, unstable induced current, etc., achieve uniform temperature distribution, simplify mold structure, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to have a more specific understanding of the technical content, characteristics and effects of the present invention, now in conjunction with the illustrated embodiment, the details are as follows:

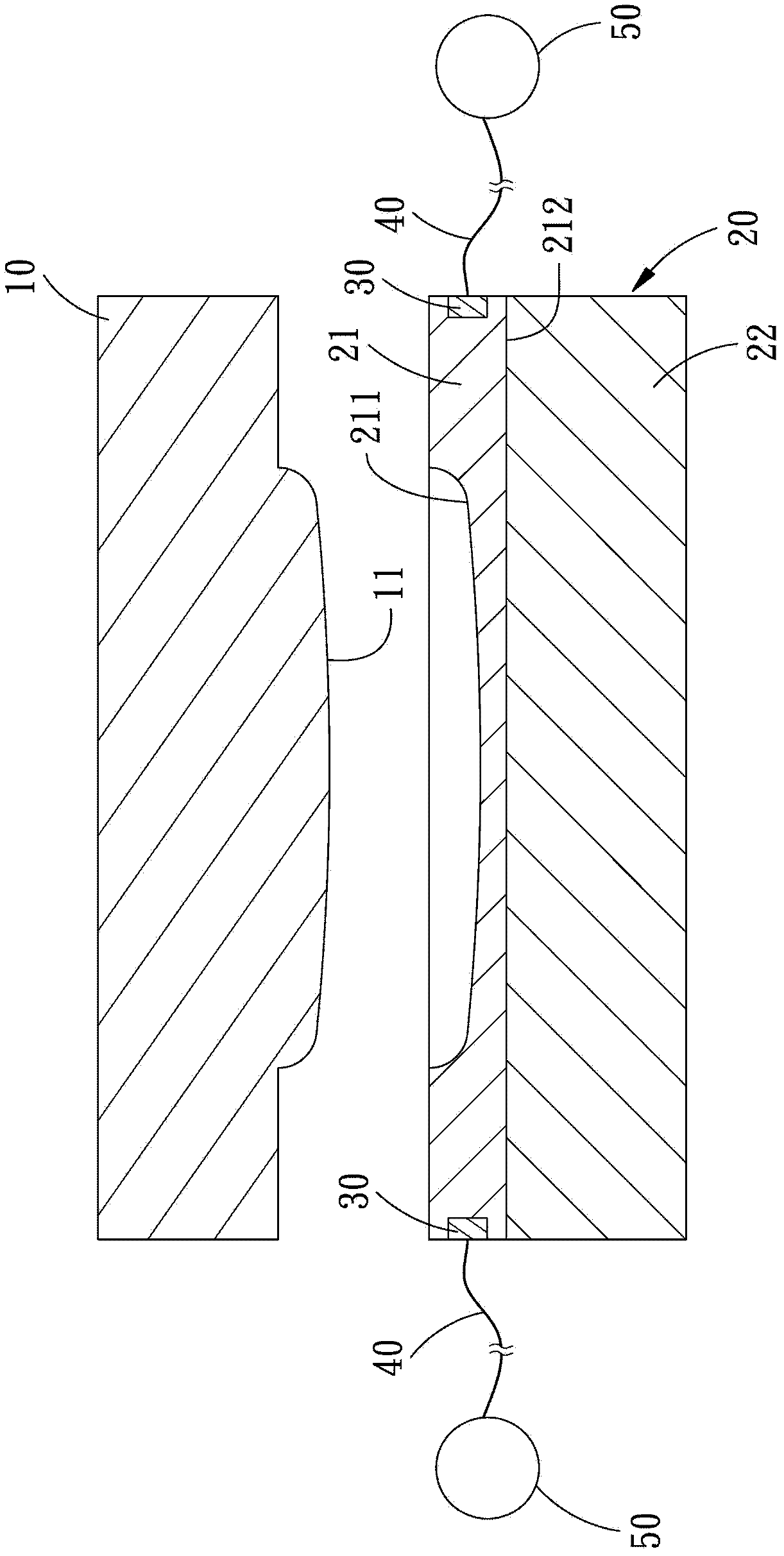

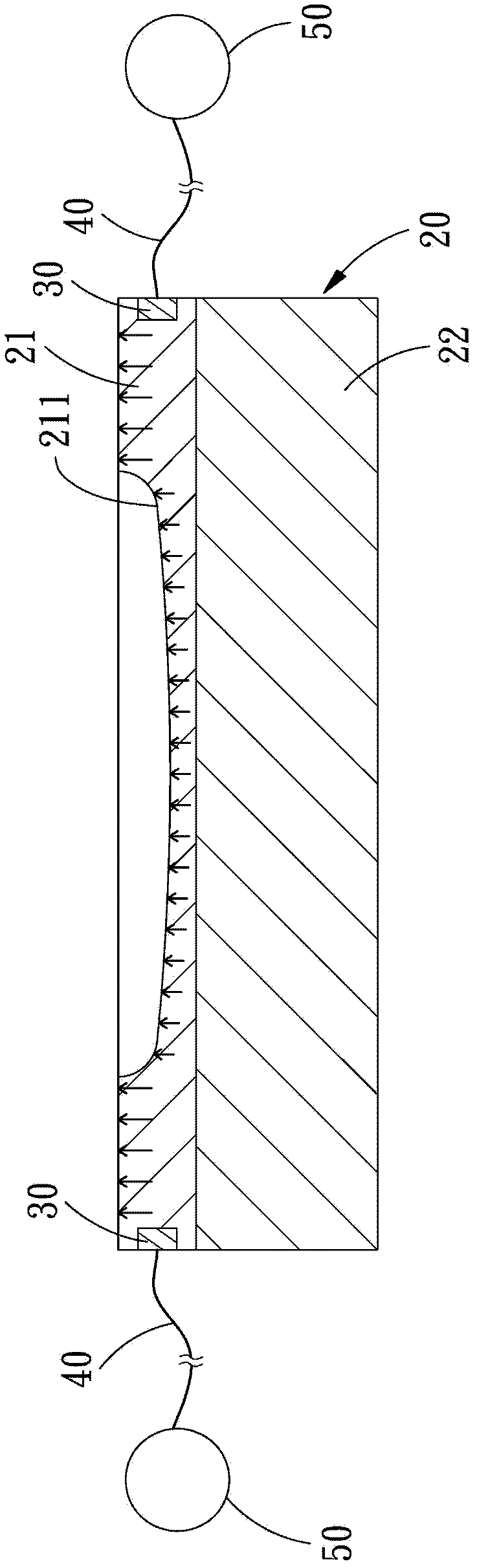

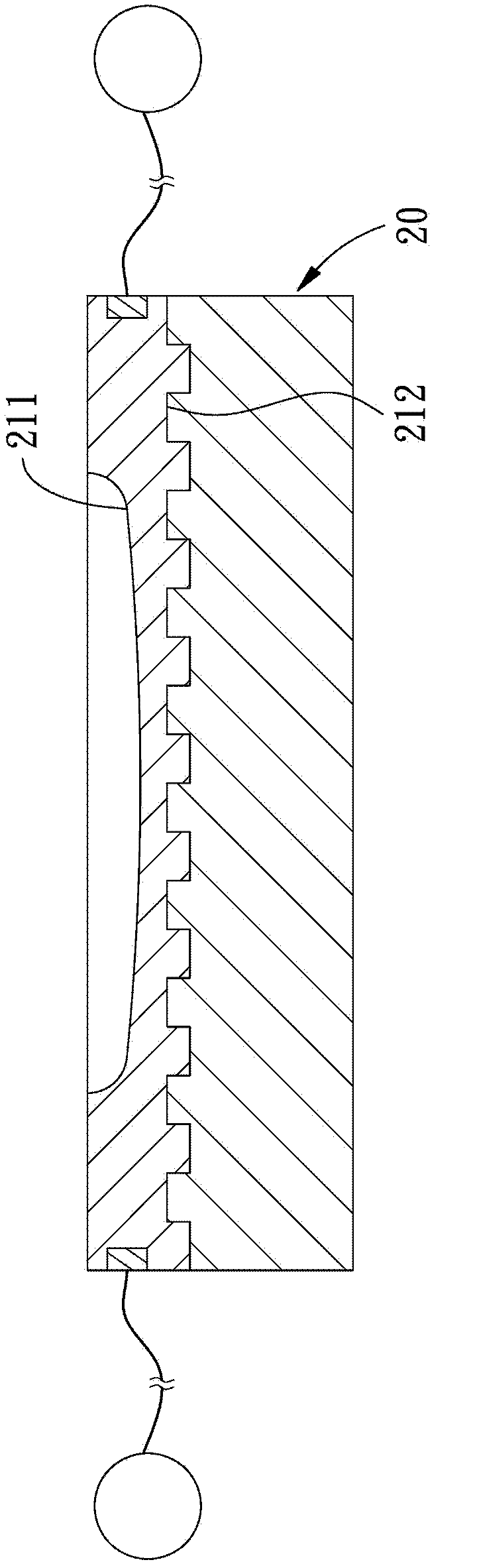

[0059] refer to figure 1 , a mold with a heating device provided by the first embodiment of the present invention is mainly composed of an upper mold 10, a lower mold 20, two conductive plates 30 and two conductive wires 40, wherein:

[0060] The upper mold 10 has an upper bonding surface 11 .

[0061] The lower mold 20 has a conductive layer 21 that is conductive and is steel (or aluminum), a lower bonding surface 211 that is arranged on the surface of the conductive layer 21 and faces the upper bonding surface 11, and a lower bonding surface 211 that is positioned on the surface of the conductive layer 21. And opposite to the insulating surface 212 of the lower bonding surface 211, an insulating layer 22 electrically insulatingly bonded to the insulating surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com