Method for producing high-magnetic-induction oriented silicon strips through three-stage normalizing

A technology of high magnetic induction orientation and silicon steel belt, which is applied in the field of high magnetic induction orientation silicon steel, can solve the problems of high cost and unfavorable energy saving, and achieve the effect of improving phase strength, improving product quality level, and increasing product magnetic induction value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

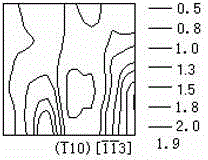

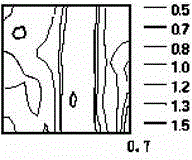

Image

Examples

Embodiment Construction

[0028] The present invention is described in detail below:

[0029] Test conditions: the test of each embodiment of the present invention adopts the casting slab composition of the existing steel type, and the values of each embodiment are in the composition and weight percentage: 2.5~3.5% Si; 0.030~0.090%C; 0.015~0.040 % AIsol; ≤0.010%N; 0.020~0.10%Cu; 0.020~0.150%Sn, 0.030~0.15%Mn, ≤0.035%S, the total amount of Cr, Ni, Mo does not exceed 0.25%, the rest is Fe and unavoidable Arbitrarily selected within the range of impurities. The thickness of the slab does not exceed 250mm.

[0030] Table 1 is the main process parameter list of each embodiment of the present invention and comparative example;

[0031] Table 2 is a list of performance testing situations of each embodiment of the present invention and comparative examples.

[0032] Each embodiment of the present invention is produced according to the following steps:

[0033] Its steps:

[0034] 1) After smelting and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com