Triaxial test device for asphalt mixture and test method

A technology of asphalt mixture and triaxial test, which is applied in the direction of applying stable tension/compression to test the strength of materials, and can solve the problems of rigid plate constraint specimen deformation, mutual interference of flexible liquid bladders, and mutual restriction of rigid loading plates. Achieve good asphalt concrete stress state, simple and easy test method, and solve the effect of corner effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

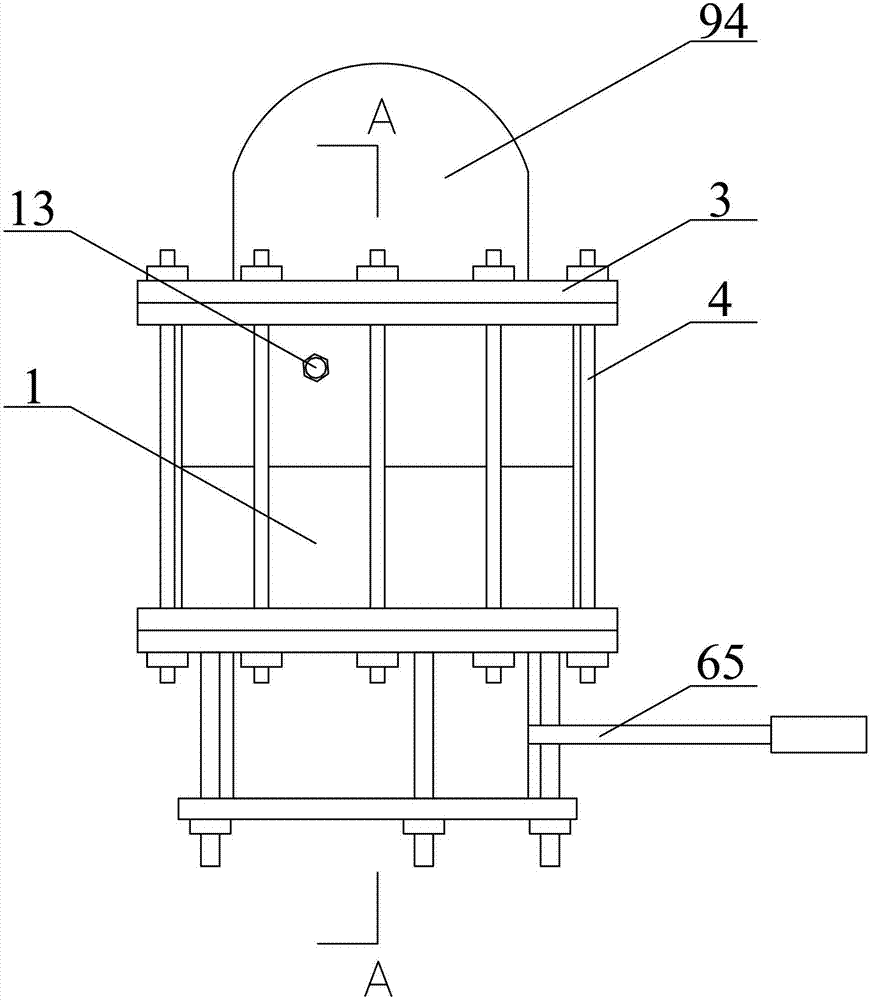

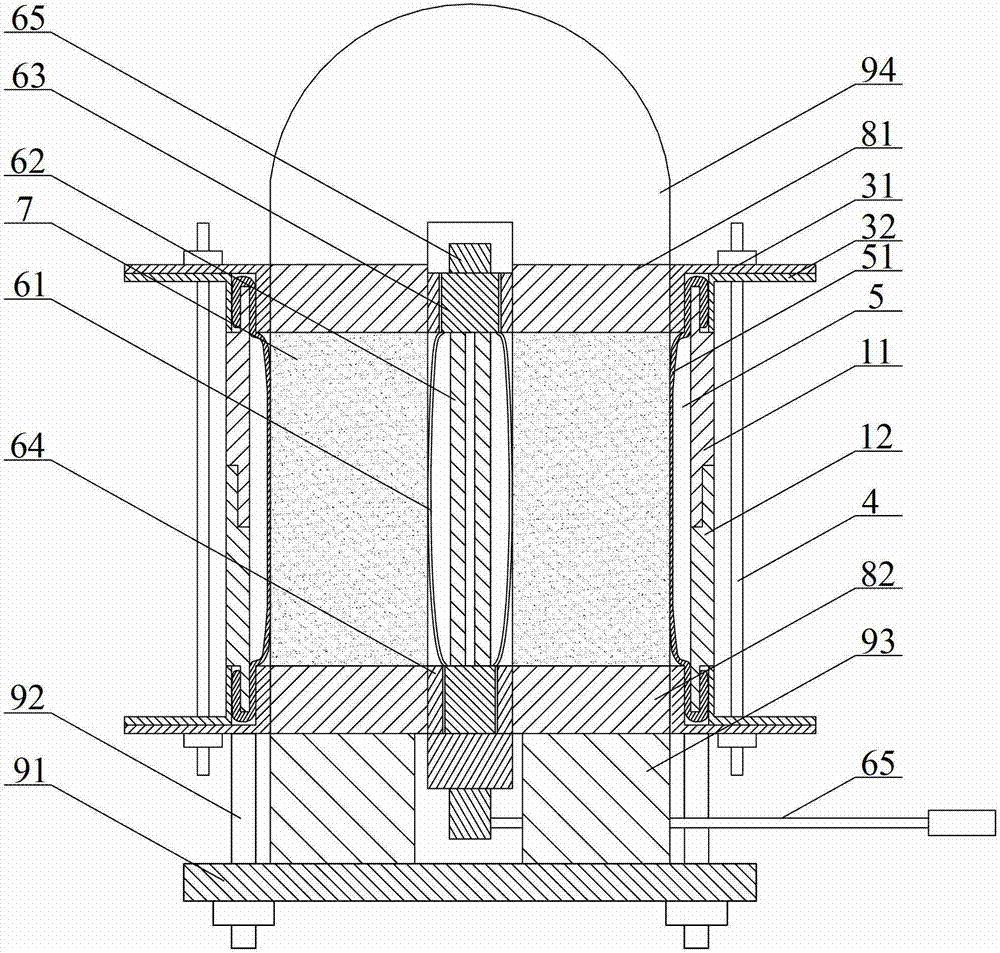

[0042] 1. Preparation of test pieces: static pressure method or rotary compaction method is used to make asphalt mixture test pieces, and core drilling samples are obtained as hollow cylinders with an outer diameter of 100mm, an inner diameter of 20mm, and a height of 100mm. In order to ensure that the drilling position is centered, a circular positioning centering cap with an outer diameter of 101 mm and an inner diameter of 21 mm was designed and manufactured. Before drilling, the positioning centering cap is placed on the surface of the test piece. If the drill bit can pass through the positioning centering cap smoothly, then It can accurately ensure that the drilling position is centered.

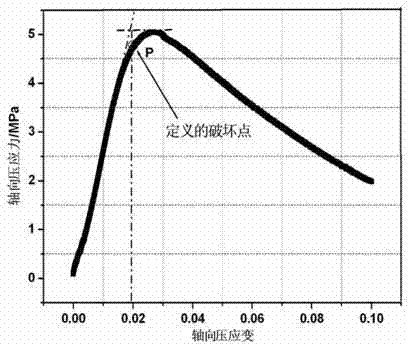

[0043] 2. Determination of the stress state of the specimen: the specimen used in the asphalt mixture airbag triaxial test is a hollow cylinder, and the inner airbag and the outer airbag respectively apply air pressure P to the inner cavity and outer wall of the specimen. 1 and P 0 , M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com