Electric-field-type driver

A drive, piezoelectric drive technology, applied in the direction of generators/motors, electrical components, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve electromagnetic noise and audio noise, cannot be widely used, and has large output displacement and other issues, to achieve the effect of low production cost, extremely power consumption, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

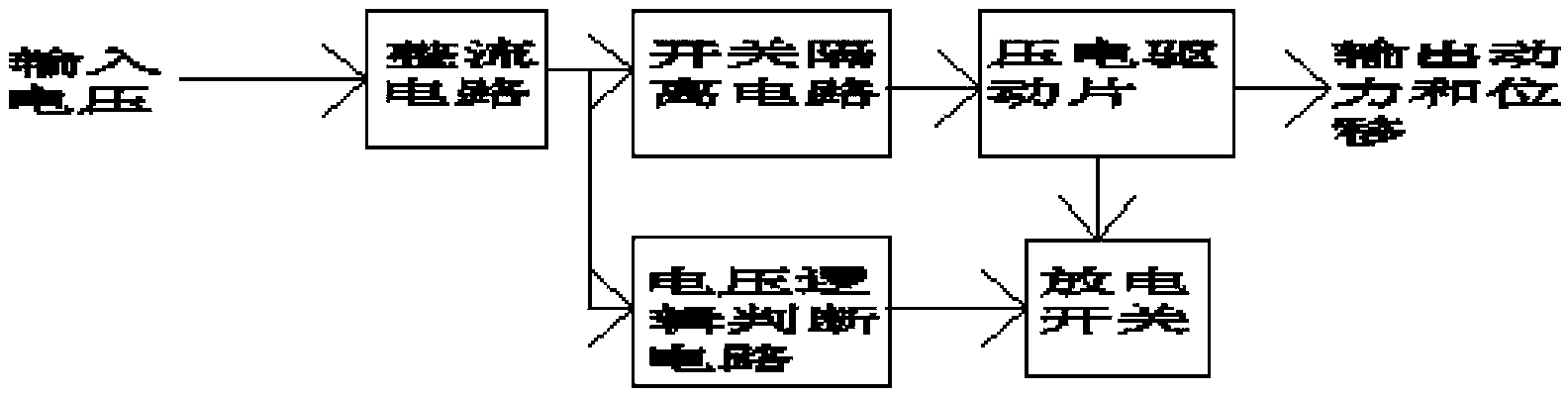

[0032] The electric field driver of the present invention includes two parts, a driving circuit and an actuator. Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

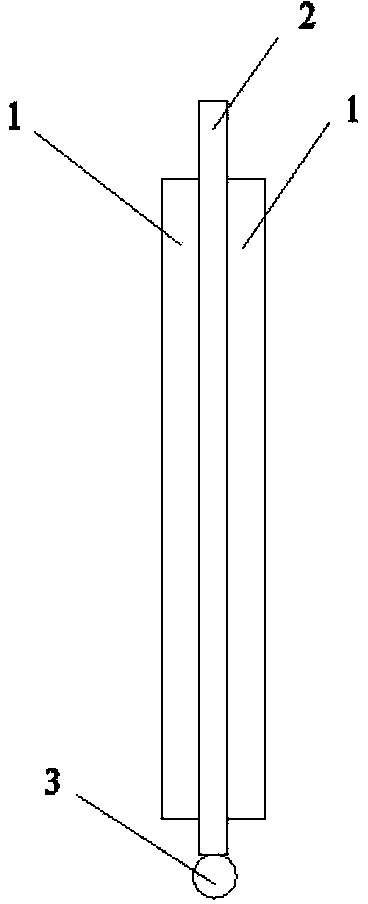

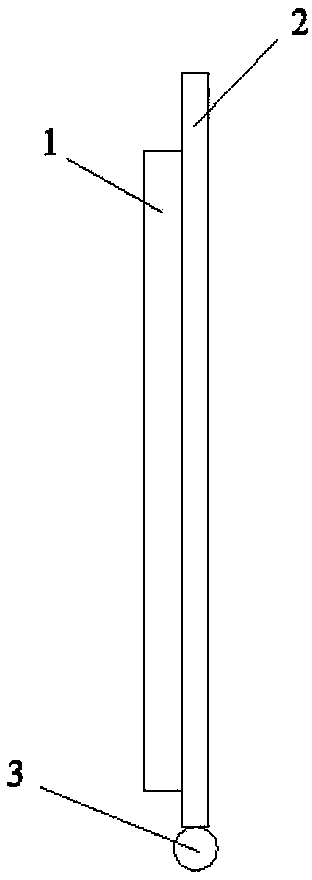

[0033] Figure 5It is an embodiment of a rotary actuator in the embodiment of the present invention. One end of the piezoelectric driving piece 5 is fixedly installed on the third connecting plate 9, and the other end of the piezoelectric driving piece 5 is installed on the first connecting plate through the first rotating shaft 3. 11, a baffle plate 6 is set next to one side of the piezoelectric driving piece 5, the baffle plate 6 is fixedly installed on the third connecting plate 9, the buffer resistor 8 is arranged on the third connecting plate 9, and the buffer resistor 8 passes through the connection The line 7 is connected in series with one electrode of the piezoelectric driving piece 5, and the two common electrode connecting lines 10 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com