Preparation method of beewax-based plastic fat

A technology for plastic fat and beeswax, which is applied in the fields of supramolecular chemical technology and plastic fat preparation for food, and achieves the effects of mild preparation conditions, high industrial development prospects and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

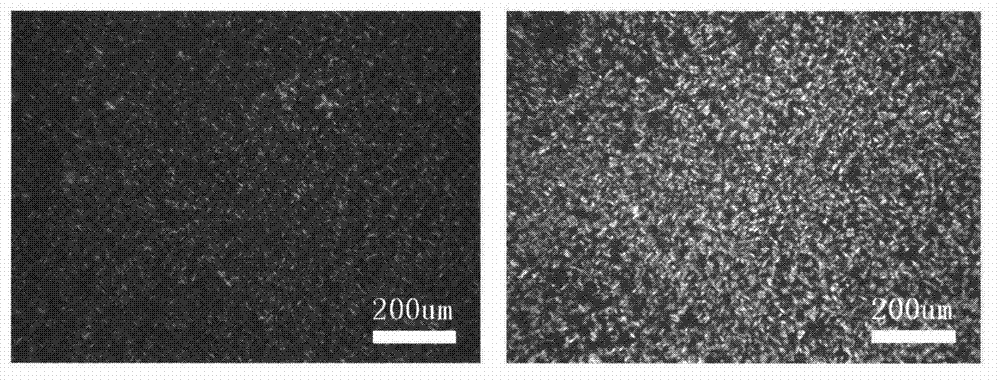

[0025] Example 1: Preparation of beeswax-canola oil-based non-emulsifying plastic fat

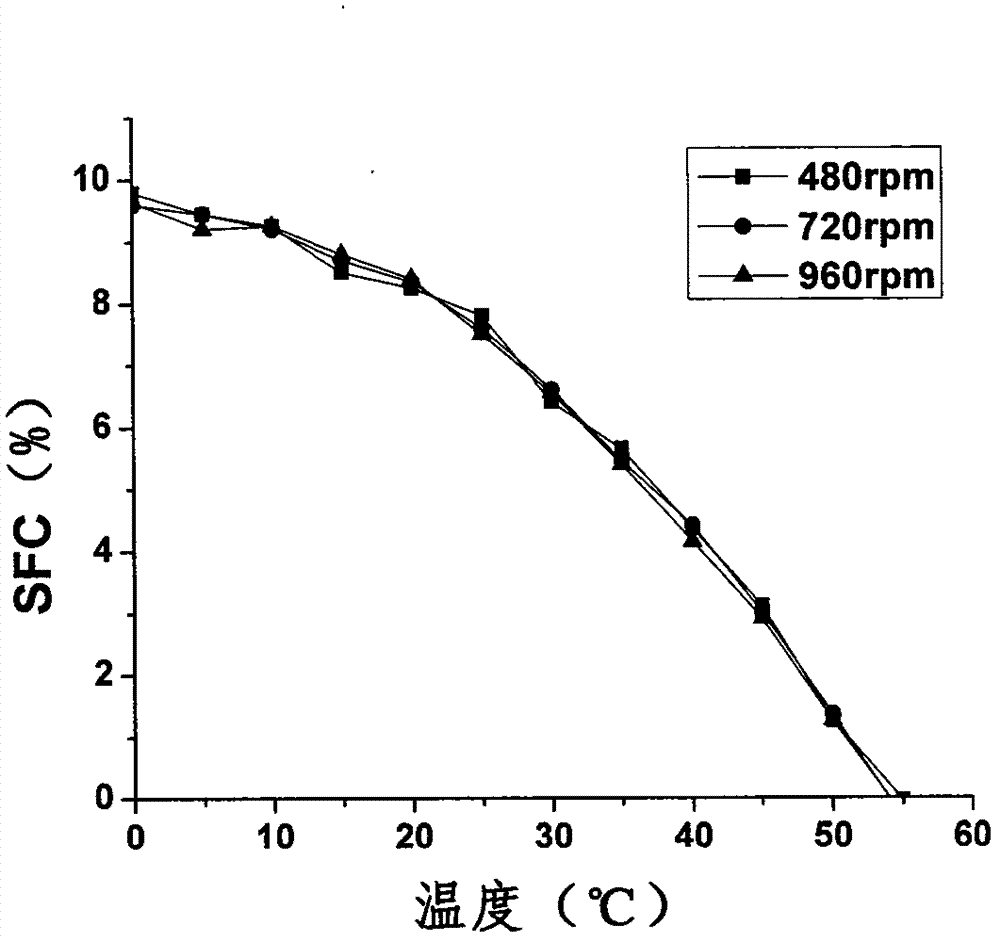

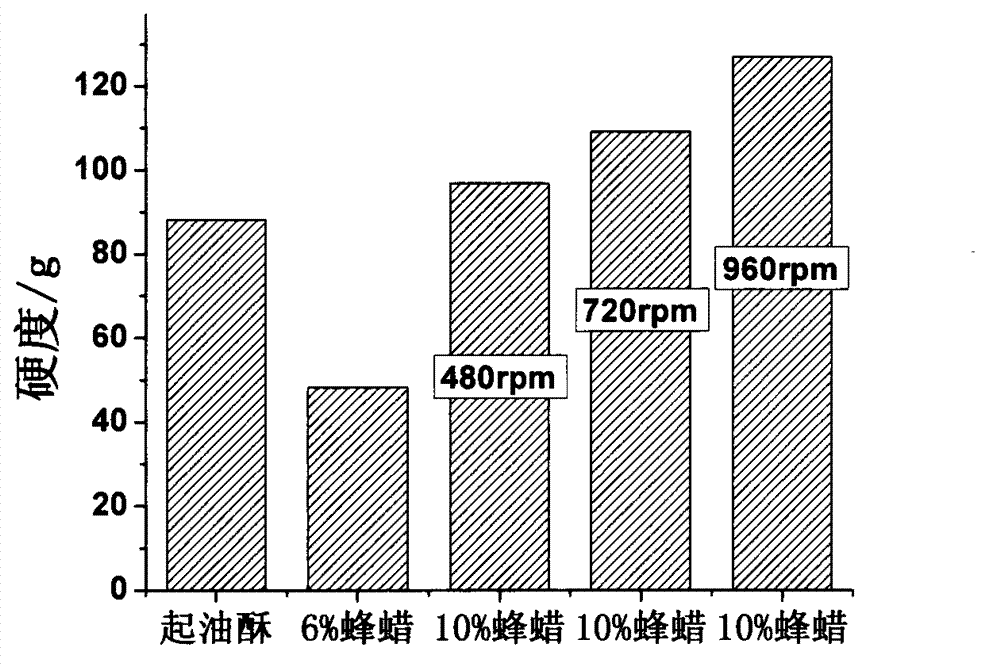

[0026] Accurately weigh 25g of canola oil in a 50mL beaker, add food-grade beeswax with mass fractions of 3%, 6%, 8%, 10%, and 15% to the above canola oil, using IKAMAG RT10 The multi-point magnetic stirrer stirred the sample at 480rpm, 720rmp, and 960rpm at a temperature of 80°C for 0.5-1h, and immediately transferred it to a refrigerator at 4°C for 24h, and then kept it at 20°C for one day to obtain the product. Fatty acid content, SFC curve, hardness.

Embodiment 2

[0027] Example 2: Preparation of beeswax-canola oil-based emulsified plastic fat

[0028] Accurately weigh 25g of canola oil in a 50mL beaker, add mass fractions of 3%, 6%, 8%, 10%, and 15% food-grade beeswax to the above canola oil, add mass fraction 10%, 20%, and 30% preheated deionized water, at a temperature of 80°C (1) homogenize twice under homogeneous pressures of 10MP, 20MP, 30MP, 40MP, and 50MP; (2) Stir at 480rpm, 720rmp, and 960rpm for 0.5-1h, and immediately transfer the sample to a refrigerator at 4°C for 24h, and then store it at 20°C for one day to obtain the product.

Embodiment 3

[0029] Embodiment 3: Physicochemical property analysis

[0030] Hardness measurement: use a physical property analyzer to measure the hardness. Take an appropriate amount of sample in a 50mL small beaker to maintain the uniformity of the system and the flatness of the test surface, and measure it after placing it at 20°C for 48h. Measuring conditions of texture analyzer: probe P5, speed before test 2mm / s, speed during test 1mm / s, speed after test 2mm / s, pressing depth 10mm. Each group of samples was measured 3 times at room temperature, the maximum value of each measurement was taken as the measurement result, and the average value of the 3 measurement results was obtained as the result.

[0031] SFC curve measurement: put the sample into the special glass sample tube of Oxford AM4000MQC low-field pulse nuclear magnetic resonance instrument, melt it in a constant temperature water bath at 100°C for 0.5h to eliminate historical crystallization, transfer it to a 60°C water bath...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com