Feed device for toothbrush hair-planting

A technology for feeding equipment and toothbrushes, which is applied in the field of toothbrush manufacturing, can solve the problems of less personnel, labor occupation, and high personnel quality requirements, and achieve the effects of improving safety and reliability, improving work efficiency, and reducing labor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

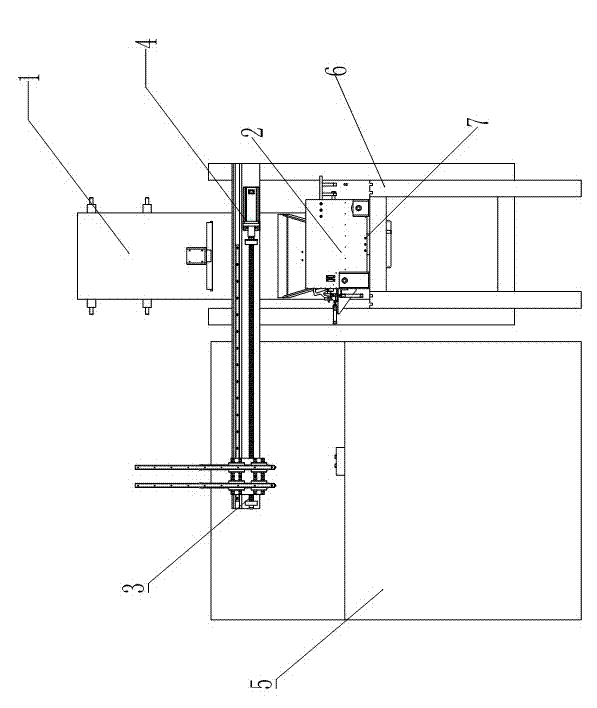

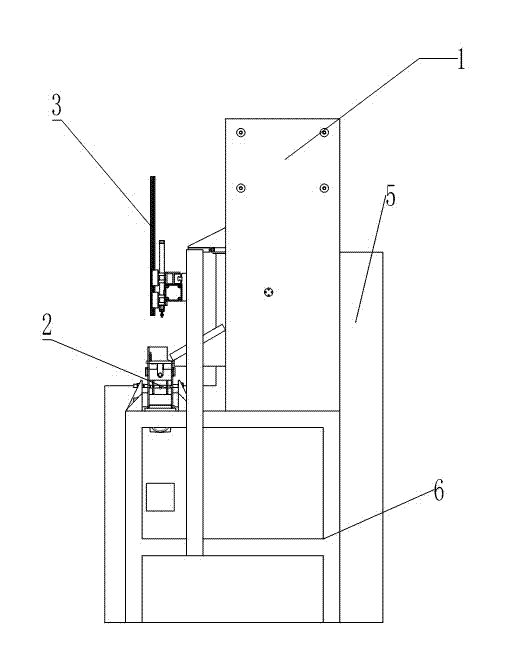

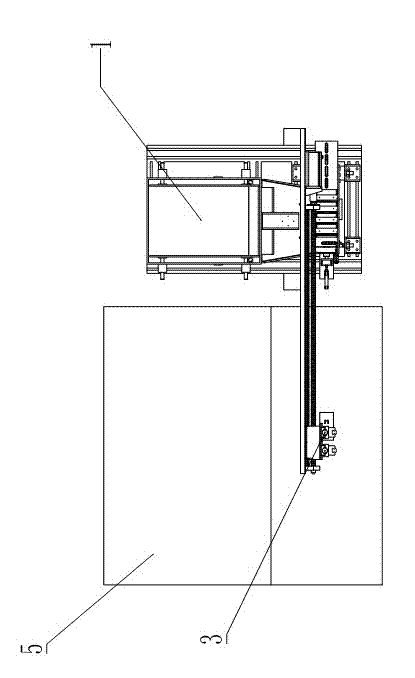

[0018] Such as Figure 1 to Figure 3 , the toothbrush hair-planting feeding device of the specific embodiment of the present invention is used for sending toothbrush into toothbrush hair-planting machine 5, and mechanical part comprises toothbrush separating machine 1, shakes brush machine 2, manipulator 3 and the support 6 that supports aforementioned parts. The electronic control part of the toothbrush hair transplanting feeding equipment includes an electrical control system and a monitoring and alarm system.

[0019] Toothbrush separator 1 separates and discharges a plurality of toothbrushes, which includes a hopper and a filter bin. The hopper preliminarily separates the toothbrushes that enter it in batches through the cylinder. Due to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com